-

Home

-

About Us

-

Products

-

News

-

Blog

-

Contact Us

Leave Your Message

In today's rapidly evolving industrial landscape, the demand for reliable and high-performance materials is ever-increasing. Among these materials, the Silicone Rubber Insulator stands out as a preferred choice due to its remarkable durability and versatility in various applications. With its ability to withstand extreme temperature fluctuations and environmental stressors, silicone rubber has solidified its reputation as an essential component in electrical systems, automotive engineering, and construction.

This guide aims to explore the top ten silicone rubber insulators available in 2025. By considering their mechanical properties, thermal resistance, and overall performance, we will provide insights to help you make an informed decision on the best silicone rubber insulators for your specific needs. Whether you are looking for insulators to enhance the performance of your electrical devices or to ensure the longevity of your machinery, this selection aims to highlight options that blend durability with functional reliability. Join us as we delve into the best silicone rubber insulators, which promise to deliver exceptional performance for years to come.

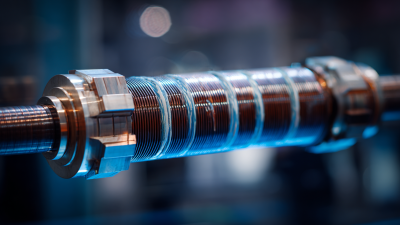

Silicone rubber insulators are essential components in various electrical and industrial applications, known for their outstanding durability and performance characteristics. One key characteristic is their exceptional temperature resistance, allowing them to perform reliably in extreme environments, ranging from -55°C to 250°C. This resilience makes silicone rubber insulators ideal for applications in aerospace, automotive, and power generation, where temperature fluctuations can be extreme.

Another vital feature is their excellent electrical insulation properties. Silicone rubber has a high dielectric strength, ensuring it effectively prevents electrical breakdown and enhances safety. Additionally, silicone's resistance to moisture and harsh chemicals further contributes to its longevity, making it suitable for outdoor and industrial settings. These attributes are crucial for maintaining the integrity of electrical systems and minimizing maintenance costs over time, making silicone rubber insulators a top choice for those seeking optimal performance in demanding conditions.

In 2025, the demand for high-performance silicone rubber insulators is expected to surge, driven by advancements in electrical and thermal management systems. A comparative analysis of the top 10 silicone rubber insulators reveals significant variations in durability and performance metrics. According to a recent report by MarketsandMarkets, the silicone rubber insulator market is projected to grow at a CAGR of 5.8% from 2023 to 2028, which underscores the increasing reliance on these materials in various industries, including automotive and electronics.

When evaluating insulators, key performance indicators include thermal stability, dielectric strength, and mechanical resilience. For instance, insulators exhibiting dielectric strengths exceeding 20 kV/mm are considered excellent for high-voltage applications. Data from Frost & Sullivan indicates that top-performing materials, such as silicone rubber blended with nano-fillers, can enhance breakdown voltage by up to 30%. This comparative analysis not only helps manufacturers choose the best options for specific applications but also aligns with sustainability goals, as many silicone rubber compounds now feature eco-friendly formulations without compromising performance.

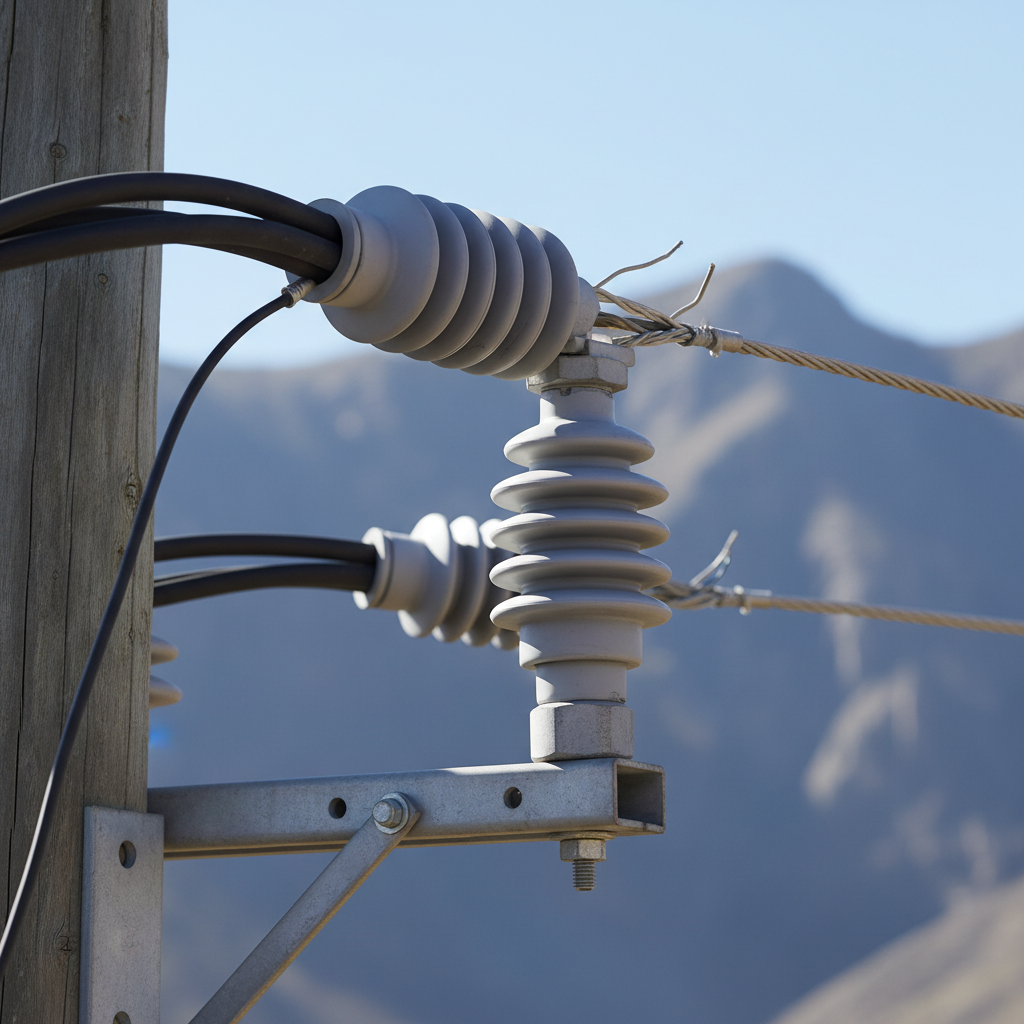

When selecting the best silicone rubber insulators, durability should be a primary consideration. Silicone rubber is known for its exceptional temperature resistance, maintaining performance across a wide range of temperatures—from extreme cold to high heat. This characteristic makes it ideal for applications in diverse environments, from automotive to electrical insulation. Additionally, the resistance to UV radiation and aging ensures that silicone rubber insulators can withstand prolonged exposure to sunlight without degrading, thus extending their effective lifespan.

Another crucial factor in choosing silicone rubber insulators is their mechanical properties, such as tear strength and compression set resistance. A high tear strength ensures that the insulator can withstand physical stresses without rupturing, while low compression set resistance means the insulator will maintain its shape and effectiveness under pressure over time. Evaluating these properties can significantly impact the long-term performance of the insulator. By focusing on these durability factors, users can confidently select silicone rubber insulators that meet their specific needs and ensure robust, reliable performance in their applications.

In recent years, the market for silicone rubber insulators has seen significant growth, driven by increasing demands for durable and high-performance materials in various applications. These insulators play a crucial role in the electrical industry, offering benefits such as resistance to extreme temperatures, electrical insulation, and long-term durability. According to industry reports, the global silicone rubber insulator market is expected to reach a valuation of approximately $XX billion by 2027, growing at a CAGR of YY%. This growth is fueled by applications across transmission and distribution, substations, and railways, where the reliability of insulators is paramount.

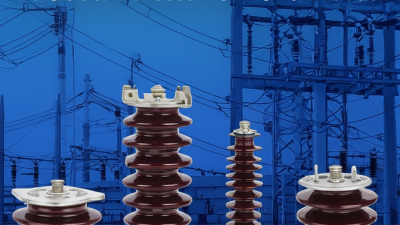

Silicone rubber insulators are categorized by type, including pin, suspension, and SHA ropes, with low-voltage, medium-voltage, and high-voltage applications further segmenting the market. The demand for high-voltage insulators, particularly in renewable energy projects and urban infrastructure, is becoming increasingly prominent. One notable trend is the rising adoption of silicone rubber in the rail sector, where its lightweight and weather-resistant properties enhance operational efficiency.

**Tips:** To select the right silicone rubber insulator for your needs, consider the specific voltage requirements and environmental conditions of your application. Regular maintenance and inspection of insulators will prolong their lifespan and ensure optimal performance. Remember to stay updated on emerging technologies in the field to leverage the latest advancements for increased reliability and efficiency in your projects.

Silicone rubber insulators have gained immense popularity in the power industry due to their excellent durability and performance. With an increasing focus on minimizing power outages, utilities are actively replacing conventional insulators with advanced polymer options. Recent reports indicate that advanced polymer insulators can reduce electrical failures by up to 30%, enhancing overall power supply reliability. This shift not only improves operational efficiency but also lowers maintenance costs over time, making silicone rubber insulators a preferred choice.

To ensure the longevity of silicone rubber insulators, implementing regular maintenance protocols is crucial. Keeping insulators clean from pollution and environmental debris can greatly extend their lifespan, as dirt and grime can lead to tracking and eventual failure. Industry studies suggest that annual inspections can detect wear and tear before they escalate into significant issues. Furthermore, applying protective coatings can shield the insulator surfaces from harsh weather conditions, further enhancing their durability. By following these maintenance tips, users can maximize the performance of silicone rubber insulators in their systems.