-

Home

-

About Us

-

Products

-

News

-

Blog

-

Contact Us

Leave Your Message

In the realm of industrial applications, safety and efficiency are paramount. One innovative solution that has emerged to address these needs is the use of Silicone Rubber Arresters. These versatile devices are designed to provide significant benefits in a variety of industrial settings, enhancing operational safety and performance. The unique properties of silicone rubber, such as its durability, flexibility, and resistance to extreme temperatures and chemicals, make Silicone Rubber Arresters an ideal choice for many industrial applications.

As industries continue to evolve, the demand for reliable and effective solutions that promote worker safety and equipment longevity has become increasingly important. Silicone Rubber Arresters stand out due to their ability to absorb shock, minimize vibrations, and provide reliable support in challenging environments. This introductory exploration delves into the top benefits of Silicone Rubber Arresters, highlighting how they contribute to enhanced safety protocols and operational efficiency across various sectors. Understanding these advantages is crucial for industries looking to adopt innovative materials that support their equipment and workforce.

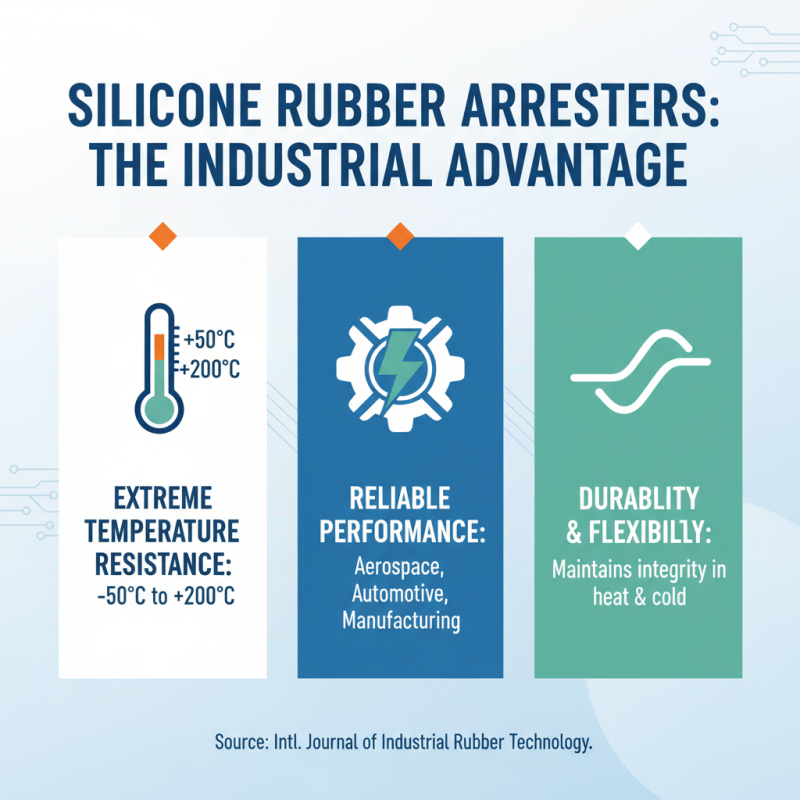

Silicone rubber arresters have gained significance in industrial applications due to their unique properties and reliable performance. One of the key characteristics of silicone rubber is its exceptional temperature resistance, capable of withstanding extreme conditions ranging from -50°C to +200°C. This temperature tolerance allows silicone rubber arresters to function effectively in diverse environments, such as aerospace, automotive, and manufacturing sectors where thermal fluctuations are common. According to a report by the International Journal of Industrial Rubber Technology, silicone materials can maintain their mechanical integrity and flexibility even under prolonged exposure to heat and cold, considerably outperforming traditional rubber compounds.

Another defining feature of silicone rubber arresters is their outstanding chemical resistance. They are less susceptible to degradation when exposed to oils, solvents, and other harsh chemicals, making them ideal for use in industries like food processing and pharmaceuticals. A study published in the Journal of Adhesion Science and Technology indicates that silicone rubber exhibits superior performance against chemical attacks compared to alternative elastomers, ensuring long-lasting durability and reliability in critical applications. Moreover, their high dielectric strength makes silicone rubber arresters suitable for electrical insulation tasks, contributing to safety and efficiency in electrical and electronic components within industrial machinery.

Silicone rubber arresters have emerged as a vital component in various industrial applications, primarily due to their unmatched safety features and performance benefits. One of the most significant advantages of silicone rubber is its ability to withstand extreme temperatures, ranging from -60°C to 230°C. This thermal stability ensures that the arresters retain their structural integrity and functionality in high-stress environments, reducing the likelihood of equipment failure or accidents. According to a report by the American Society for Testing and Materials (ASTM), materials that can endure such temperature variations can significantly decrease downtime and maintenance costs in manufacturing processes.

In addition to thermal resilience, silicone rubber arresters provide excellent damping properties, effectively minimizing vibration and shock in machinery. This capability not only enhances the safety of industrial operations by protecting equipment but also contributes to increased worker safety. A study from the Occupational Safety and Health Administration (OSHA) indicated that vibration-related injuries account for a considerable percentage of workplace incidents. By integrating silicone rubber arresters into equipment designs, businesses can mitigate these risks and improve overall operational safety.

Tips: When selecting silicone rubber arresters, consider factors such as load capacity, environmental exposure, and compatibility with other materials. Regular inspections and maintenance of arresters can also ensure continued safety and performance longevity, further enhancing productivity in demanding industrial environments.

Silicone rubber arresters are increasingly recognized for their exceptional durability and longevity, making them an ideal choice for various industrial applications. Unlike traditional materials, silicone rubber exhibits remarkable resistance to extreme temperatures, UV exposure, and harsh environmental conditions. This resilience ensures that silicone rubber arresters maintain their structural integrity and functionality over extended periods, minimizing the need for frequent replacements and repairs. This characteristic not only enhances operational efficiency but also significantly reduces maintenance costs for businesses.

Furthermore, the flexibility and adaptability of silicone rubber allow for a wide range of applications within different industries. Whether used in vibration dampening, cushioning, or as protective barriers, these arresters can effectively absorb and disperse energy without compromising their physical properties. Their ability to perform reliably in both high and low temperatures means that they can be utilized in diverse settings, from manufacturing plants to outdoor installations. This versatility, coupled with their durability, underscores the critical role silicone rubber arresters play in ensuring longevity and reliability in industrial operations.

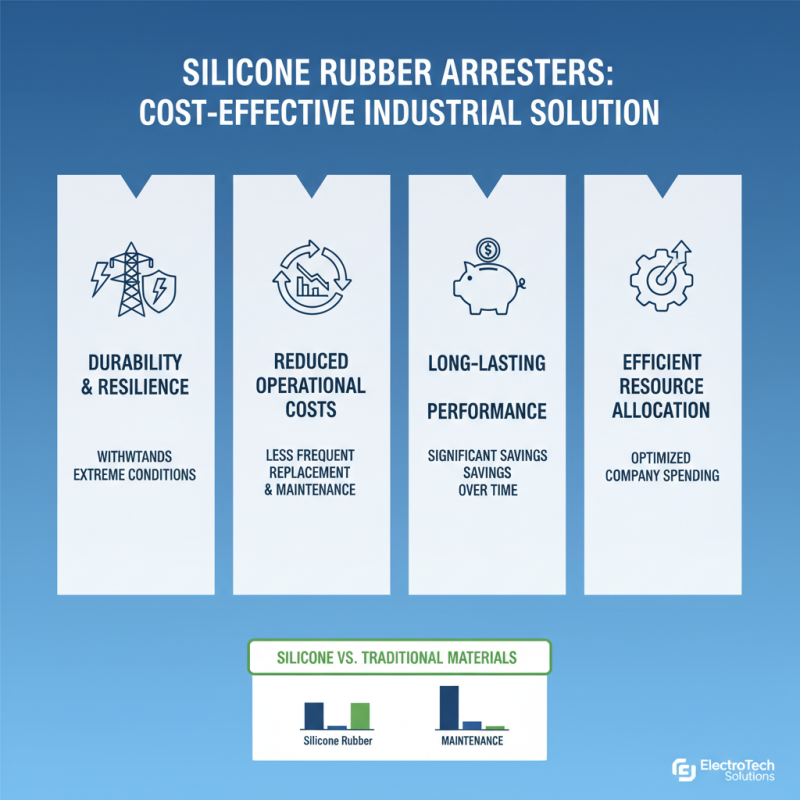

Silicone rubber arresters have gained traction in industrial applications due to their exceptional cost-effectiveness. The manufacturing of these arresters involves a blend of silicone rubber properties that offer durability and resilience, ultimately leading to lower operational costs. Unlike traditional materials, silicone rubber can withstand extreme temperatures and harsh environmental conditions, reducing the need for frequent replacements and maintenance. This long-lasting performance translates into significant savings over time, allowing companies to allocate their resources more efficiently.

Additionally, the lightweight nature of silicone rubber arresters promotes ease of installation and handling, further contributing to their cost-effectiveness. When compared to heavier, more rigid materials, silicone rubber not only simplifies the logistics of transport and setup but also minimizes labor costs. The flexibility and adaptability of silicone rubber allow for custom solutions tailored to specific industrial needs, enhancing operational efficiency without crossing budgetary constraints. As industries strive for economical yet efficient solutions, the continued adoption of silicone rubber arresters stands as a testament to their value in enhancing productivity while managing costs effectively.

When comparing silicone rubber arresters to traditional materials like metal or plastic, several key advantages of silicone rubber arise, particularly in industrial settings. Silicone rubber is inherently more flexible and resilient, which allows it to withstand a wider range of temperatures and harsh environmental conditions. This elasticity makes it less likely to crack or warp over time compared to its traditional counterparts, ensuring longer service life and reduced maintenance costs. Additionally, silicone rubber's resistance to chemicals, UV light, and ozone further enhances its performance in demanding applications.

Tips for selecting silicone rubber arresters include assessing the specific needs of your application. Consider factors such as temperature limits, exposure to chemicals, and required flexibility. Opt for silicone arresters that are rated for your industry’s requirements, as this will optimize performance and reliability. Furthermore, ensure that you evaluate the physical properties of the silicone in terms of durometer hardness, as this can influence how the arresters will behave under load.

Another advantage of using silicone rubber arresters is their lightweight nature, which simplifies installation and handling compared to heavier traditional materials. This can lead to overall efficiency improvements in the workplace, facilitating easier replacements and adjustments. Keep in mind that while silicone rubber can be initially more expensive, its durability and performance often result in greater cost-effectiveness over time. When making your choice, balance the initial investment with projected long-term savings.

| Feature | Silicone Rubber Arresters | Traditional Materials |

|---|---|---|

| Temperature Resistance | -50°C to 250°C | -20°C to 120°C |

| Chemical Resistance | Excellent | Moderate |

| Durability | Highly Durable | Less Durable |

| Flexibility | High Flexibility | Rigid |

| Weight | Lightweight | Heavier |

| Cost Efficiency | Higher Initial Cost | Lower Initial Cost |

| Maintenance | Low Maintenance | Higher Maintenance |