-

Home

-

About Us

-

Products

-

News

-

Blog

-

Contact Us

Leave Your Message

In the realm of electrical engineering and surge protection, the significance of Zinc Oxide Arresters has gained unparalleled recognition. Industry expert Dr. Emily Carter, a leading figure in surge protection technologies, asserts, "The efficiency of Zinc Oxide Arresters in safeguarding electrical systems cannot be overstated, as they provide both robustness and reliability under extreme conditions." This statement encapsulates the essence of why these devices are paramount for protecting sensitive electrical infrastructure from surge events.

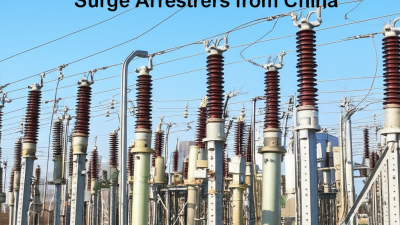

Zinc Oxide Arresters play a crucial role in various applications, ranging from substations to industrial plants, ensuring that electrical equipment remains undamaged during unexpected voltage spikes. Their unique properties, including high non-linearity and low residual voltage, have made them the preferred choice for engineers worldwide. As the demand for reliable surge protection intensifies, understanding the top benefits of Zinc Oxide Arresters becomes essential for anyone involved in electrical system design and maintenance. This article will explore the top ten advantages of integrating Zinc Oxide Arresters into electrical systems, highlighting their impact on safety, efficiency, and longevity.

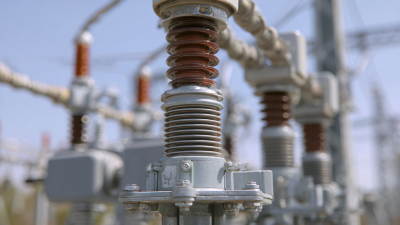

Zinc oxide arresters play a crucial role in protecting electrical systems from surges caused by lightning strikes or switching events. Unlike traditional arresters, which often use silicon carbide, zinc oxide offers superior non-linear resistance properties. This means that zinc oxide arresters can effectively clamp voltage surges while allowing normal operational voltages to pass through without significant interference. Their ability to absorb and redirect excess energy makes them an essential component in surge protection systems.

The design and functionality of zinc oxide arresters are centered around their ability to provide a fast and efficient response to voltage spikes. By diverting excessive currents away from sensitive equipment, zinc oxide arresters help maintain the integrity and longevity of electrical devices. The compact size and robust performance of these devices enable their use in various applications, ranging from residential setups to large industrial operations.

As electrical systems become increasingly complex, understanding and implementing zinc oxide arresters is vital for ensuring reliable surge protection and minimizing potential damage.

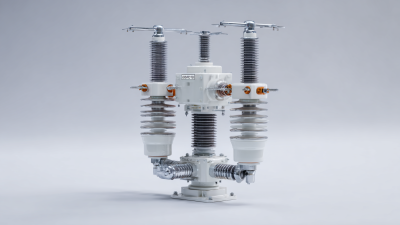

Zinc oxide arresters have become a popular choice in surge protection, largely due to their superior performance when compared to traditional devices. One of the key advantages of zinc oxide is its ability to clamp voltage levels effectively during a surge event. Unlike traditional silicon-based varistors, zinc oxide arresters offer a much lower clamping voltage, which minimizes the risk of damage to sensitive electronic equipment. This feature ensures that the connected devices are shielded from potentially harmful transients, enhancing their longevity and reliability.

Another significant benefit is the improved energy handling capacity of zinc oxide arresters. They can handle larger surge currents without degradation, making them particularly suited for high-demand applications. This durability translates into reduced maintenance costs and a lower likelihood of device failure. Furthermore, zinc oxide technology is compact and lightweight, which facilitates easier installation and integration into existing systems. These attributes collectively position zinc oxide arresters as an advanced solution for modern surge protection needs, making them a vital component in safeguarding electrical infrastructure.

| Benefit | Description | Comparison to Traditional Devices |

|---|---|---|

| Higher Energy Absorption | Zinc oxide arresters can absorb large voltage spikes, protecting sensitive electronics. | Traditional devices often fail to handle very high energy surges. |

| Compact Size | Their smaller form factor allows for easier installation in confined spaces. | Conventional devices are bulkier and require more installation space. |

| Lower Clamping Voltage | Offers effective protection at lower voltage levels, enhancing safety. | Older devices may clamp at higher voltages, risking damage to electronics. |

| Longer Lifespan | Durable materials extend the life of the device significantly. | Traditional devices may fail much sooner under stress. |

| Temperature Resilience | Resistant to temperature variations, ensuring reliable operation. | Older models may degrade under extreme temperatures. |

| Environmentally Friendly | Zinc oxide is less harmful to the environment compared to alternative materials. | Conventional devices may use materials that are hazardous to the environment. |

| Efficient Energy Handling | Efficiently channels excess energy away from systems, protecting them. | Traditional models may not effectively redirect energy surges. |

| Enhanced Safety Features | Built-in mechanisms reduce risks of failure or fire. | Older devices lack modern safety features, posing greater risks. |

| Cost-Effectiveness | Better long-term investment due to fewer replacements needed. | Traditional devices may save on initial costs but incur more replacements. |

| Versatile Applications | Suitable for a wide range of applications from residential to industrial. | Older devices may be limited to specific applications only. |

Zinc oxide arresters play a critical role in enhancing the reliability and safety of electrical systems. By effectively clamping voltage surges, they protect sensitive equipment from damage caused by transient overvoltage events. Unlike traditional metal oxide varistors, zinc oxide arresters provide a superior non-linear resistance behavior, allowing them to conduct excess voltage to the ground swiftly while minimizing energy losses. This fast response time is essential for maintaining the operational integrity of power systems, especially in environments prone to lightning strikes or switching surges.

In addition to their protective capabilities, zinc oxide arresters contribute to the overall safety of electrical installations. Their robust design ensures a high level of thermal and mechanical stability, effectively preventing premature failure. This reliability minimizes the risk of fire hazards and electric shock, making them an ideal choice for critical infrastructure. Moreover, their maintenance-free operation further enhances system safety, as they do not require frequent inspections or replacements, allowing operators to focus on their core responsibilities.

As such, the adoption of zinc oxide arresters is not only a precautionary measure but a strategic approach to fostering safer and more dependable electrical systems.

When installing zinc oxide arresters, several critical considerations ensure their optimal performance in surge protection systems. First, it is essential to select the appropriate voltage rating. The arresters should be rated above the operating voltage of the system to prevent premature failure while effectively handling surges. Proper spacing is also crucial; ensuring that the arresters are strategically placed along the electrical line minimizes the risk of electrical arcs and enhances the overall surge protection capability.

Another key consideration is the grounding system. A robust grounding connection is vital for zinc oxide arresters to function effectively. This connection helps in safely dissipating surge energy into the ground, reducing potential damage to electrical equipment. Maintenance checks are equally important; periodic inspections can identify wear or damage, ensuring that the arresters continue to operate at peak efficiency. Integrating these considerations into the installation process will amplify the protective benefits of zinc oxide arresters, safeguarding infrastructure against potentially damaging electrical surges.

Zinc oxide arresters have gained recognition in the electrical industry as a vital component for effective surge protection. With a focus on the maintenance and longevity of these devices, it's essential to note that their performance is closely tied to regular inspection and proper environmental conditions. Industry reports indicate that routine maintenance can extend the life of zinc oxide arresters by 30%-50%. This is particularly crucial as lightning and transient voltage events can demand high energy absorption levels, challenging the durability of these components.

Furthermore, the effective protection offered by zinc oxide arresters is significantly influenced by their installation environment. Data from research conducted by the Institute of Electrical and Electronics Engineers (IEEE) suggests that maintaining a clean and dry installation environment can enhance the operational lifespan of arresters, with some units showing optimal performance up to 20 years under ideal conditions. Regular testing and prompt replacement of damaged units also play a critical role in ensuring reliable surge protection, minimizing the risk of equipment failure and costly downtime. By prioritizing the maintenance and careful management of zinc oxide arresters, organizations can greatly contribute to enhanced electrical system resilience.