-

Home

-

About Us

-

Products

-

News

-

Blog

-

Contact Us

Leave Your Message

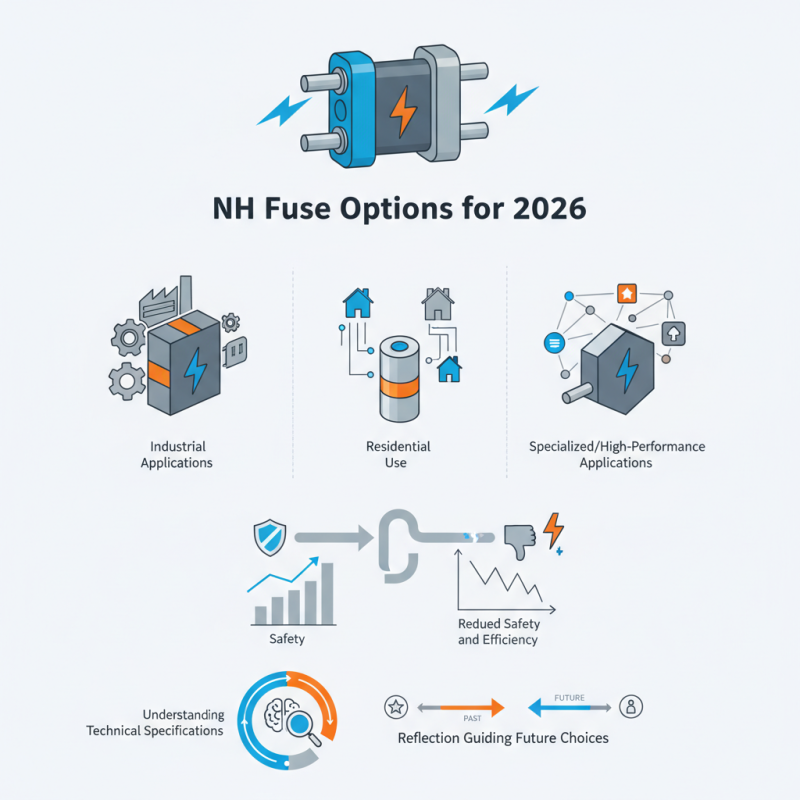

As the demand for reliable power protection grows, the choice of the right NH fuse becomes increasingly critical. According to industry expert Mark Thompson, “Choosing the right NH fuse can make or break electrical safety.” Navigating through the options available for 2026 requires careful consideration.

NH fuses come in various ratings and designs. Each type serves distinct applications. For example, fuses designed for industrial settings may differ significantly from those used in residential areas. The fuse’s ability to interrupt current under specific conditions is essential. Yet, many still struggle to grasp the technical specifications.

Moreover, some users mistakenly overestimate their knowledge. This can lead to poor choices that compromise safety and efficiency. A product that works well for one application may fail miserably in another. As we explore the best NH fuse options for 2026, reflection on past decisions can guide future ones. Understanding the intricacies of NH fuses is not just beneficial; it’s vital for creating a safe environment.

NH fuses are essential for electrical protection. In 2026, various types are available. Each type serves specific needs and applications. Understanding these options is vital for selecting the right fuse.

There are traditional NH fuses, which are popular for their reliability. These fuses can handle high current loads. They often come in various ratings, making them suitable for different installations. Another option is fast-acting NH fuses. These are designed to respond quickly to overcurrents. They protect sensitive equipment from damage.

For those needing higher voltage options, NH fuses provide various voltage ratings as well. The selection process can be challenging. It's crucial to assess the specific application requirements. Factors such as current rating and breaking capacity matter. Miscalculating these could lead to inadequate protection. Keeping an open mind about alternatives is important. Many options exist, and each presents unique advantages and drawbacks.

This chart illustrates the projected market share of various NH fuse types for the year 2026, highlighting their anticipated performance and adoption rates in industrial settings.

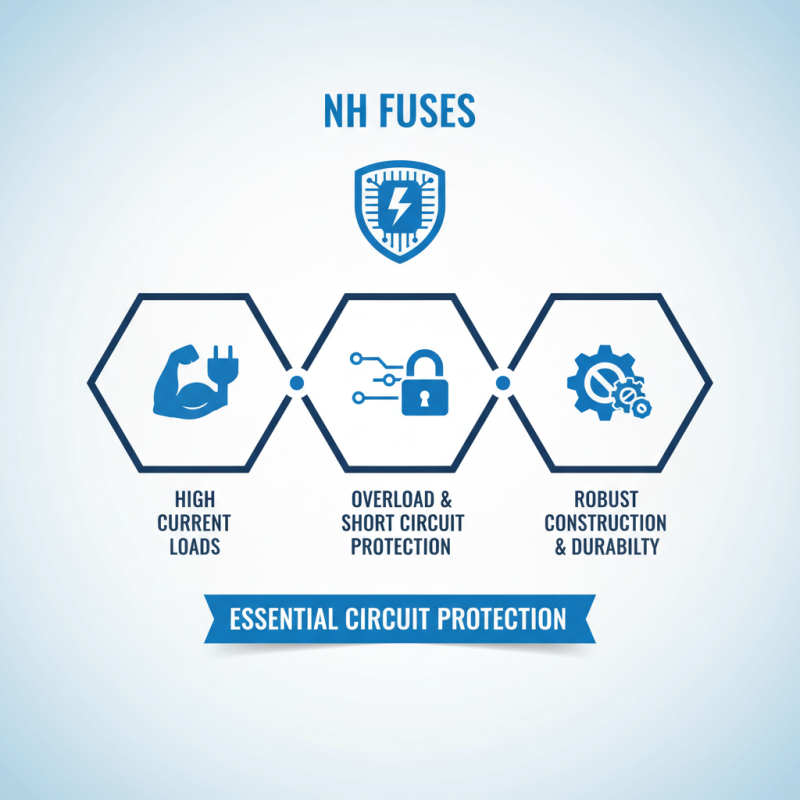

NH fuses are essential for protecting electrical circuits. They come in various options, each with specific features. One key feature is their ability to handle high current loads. They provide reliable protection against overloads and short circuits. Additionally, NH fuses have a robust construction. This ensures durability even in extreme conditions.

When choosing NH fuses, consider their breaking capacity. This indicates how much current they can safely interrupt. Another feature to examine is their dimension and size. Fuses that are too large may not fit your existing installations. Smaller options might not provide enough protection.

It's also important to reflect on installation challenges. Some users find it difficult to replace fuses in tight spaces. Regular maintenance is crucial. Neglecting to check the fuses can lead to unexpected failures. Making informed decisions about your fuse options is key. Analyze your needs carefully before selecting the best NH fuse for your system.

When considering NH fuse options for 2026, an analysis of various brands reveals significant variations in performance and reliability. Recent industry reports indicate that quality fuses can decrease downtime by up to 30%. This is crucial in sectors where continuous operation is essential. Brands differ greatly in their thermal characteristics and interrupting capacities, impacting their suitability for specific applications.

It's essential to examine individual specifications closely. Many fuses claim high performance, but actual results may vary. Some may not handle unexpected surges well, leading to premature failures. This lack of consistency can be problematic, especially in critical systems. Investing in reliable fuse options can enhance safety and efficiency.

Tips: Always check for third-party testing data. Look for fuses with temperature ratings aligned with your environment. Specific applications may require unique characteristics. Relying solely on brand reputation can be misleading. Ensure that you maintain an inventory of fuses suited to varying conditions. Regular assessments of fuse performance can help in avoiding future issues. This proactive approach can save significant costs and enhance operational stability.

| Feature | Option A | Option B | Option C |

|---|---|---|---|

| Voltage Rating | 500V | 500V | 630V |

| Current Rating | 63A | 80A | 100A |

| Breaking Capacity | 120kA | 150kA | 200kA |

| Dimensions (mm) | 30 x 60 | 33 x 65 | 40 x 70 |

| Operating Temperature | -25 to +60°C | -20 to +55°C | -30 to +70°C |

| Certifications | IEC, UL | IEC, CE | IEC, UL |

When selecting the right NH fuse for 2026, several factors come into play. The voltage rating is crucial. High voltage fuses are necessary for certain applications. Be mindful of the current rating as well. Too low or too high can lead to equipment failure. Each application has its specific demands.

Another consideration is the fuse's breaking capacity. This indicates the fuse's ability to interrupt a fault current. Choose a fuse that can handle potential short circuit levels. This is critical for safety and reliability. Additionally, think about the installation environment. Will it be exposed to moisture or extreme temperatures? Those factors can affect fuse performance.

Lastly, consider the physical size of the fuse. Space constraints can limit your options. Not all fuses fit into every system. Some may require adapters or modifications. Reflect on your specific needs. Each choice can impact overall system efficiency. Taking time to evaluate these details can prevent issues later.

As we look ahead to 2026, the landscape of NH fuse technology is evolving. Innovations are reshaping their efficiency and safety profiles. The adoption of smart technology is one key trend. This allows for real-time monitoring and automated response in critical situations. Increased reliability in electrical systems is a top priority for industries everywhere.

Tips: Consider investing in fuses with advanced thermal and overload protection. This can prevent equipment damage during surges. Fuses designed for harsh environments also show promise. They offer better resilience against dust, moisture, and temperature fluctuations.

The push toward sustainability is impacting NH fuse usage. Manufacturers are focusing on eco-friendly materials. This shift reduces the environmental footprint of electrical systems. However, there are challenges, especially in balancing cost and sustainability. Companies must weigh the benefits against potential price hikes.

Tips: Keep an eye on certifications for environmentally-friendly products. This can guide better purchasing decisions. Monitoring evolving regulations around energy efficiency is also essential.