-

Home

-

About Us

-

Products

-

News

-

Blog

-

Contact Us

Leave Your Message

In today’s rapidly evolving electrical landscape, the need for effective surge protection has never been more critical. This is where the Polymeric Surge Arrester comes into play, providing essential defense against voltage spikes that can lead to costly equipment damage and downtime. Selecting the right polymeric surge arrester involves not only understanding the technical specifications but also adhering to best practices to ensure optimal performance and reliability.

In this guide, we will explore seven best practices for selecting a polymeric surge arrester, emphasizing key factors such as material quality, environmental considerations, and installation techniques. Whether you are a seasoned engineer or new to the field, these insights will equip you with the knowledge necessary to make informed decisions that enhance system resilience and longevity.

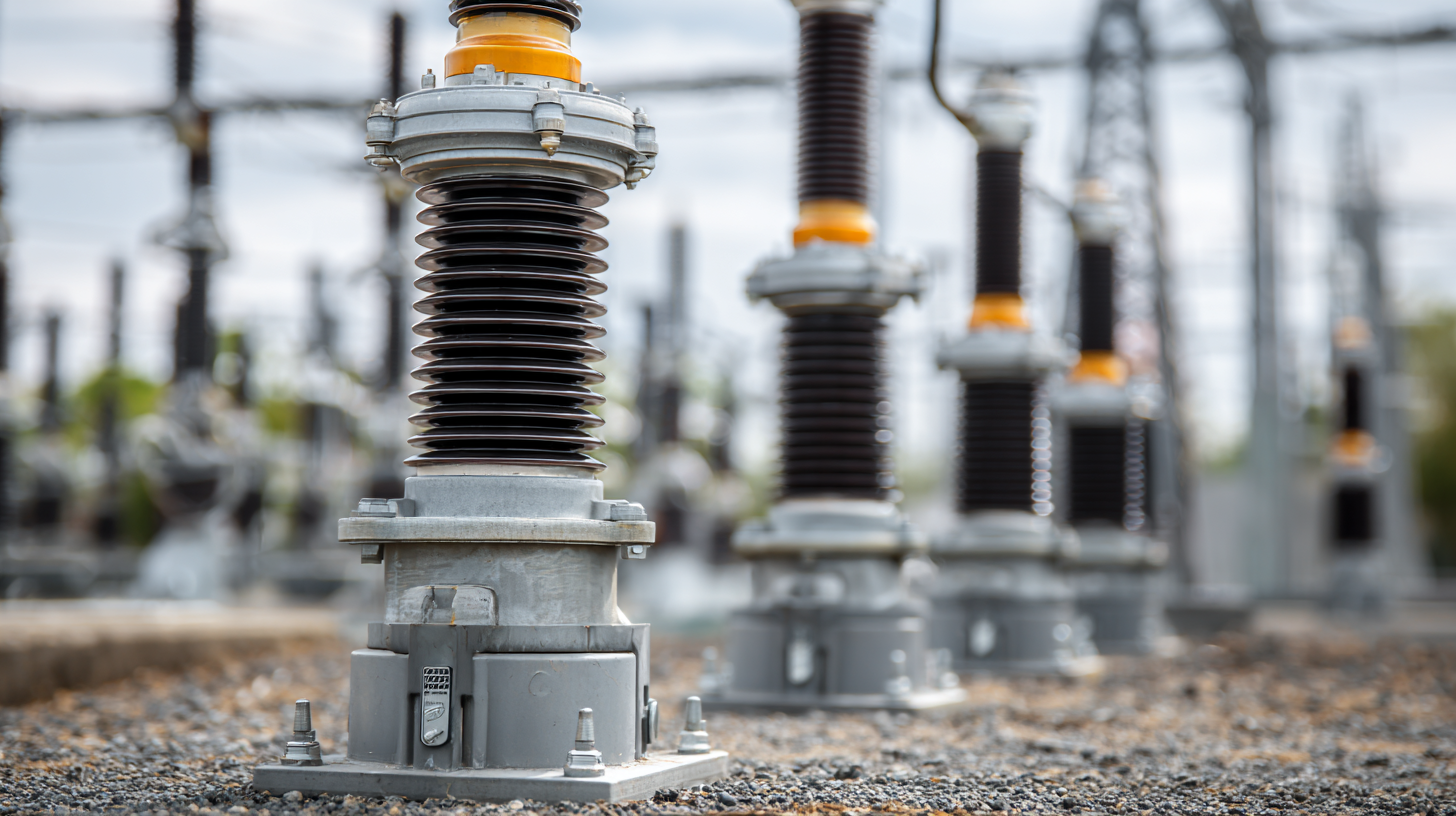

Polymeric surge arresters are essential components in modern electrical systems, providing critical protection against voltage spikes that can damage sensitive equipment. Their importance cannot be overstated, as they help maintain the integrity and reliability of power networks, particularly in industrial and commercial settings. Utilizing polymeric materials, these arresters offer excellent electrical properties and durability, making them highly effective at dissipating excessive energy during transients.

When selecting a polymeric surge arrester, it’s vital to consider its voltage rating and energy absorption capacity. Tip: Always choose a device that is compatible with the maximum voltage levels of your system to ensure optimal protection. Additionally, assessing the environmental conditions — such as temperature fluctuations and exposure to UV radiation — can guide you in selecting a model that can withstand harsh environments.

Another important aspect to consider is the installation and maintenance requirements of polymeric surge arresters. Tip: Opt for products that simplify the installation process and offer clear maintenance guidelines to ensure longevity and performance. Regular inspections and testing can help identify potential issues before they escalate, further enhancing the reliability of your electrical system.

When selecting a polymeric surge arrester, several key factors must be considered to ensure optimal protection for your electrical systems. First and foremost, understanding the application environment is essential. Polymeric surge arresters are designed to work in various conditions, including outdoor and indoor settings.

Evaluating the temperature range, humidity, and potential exposure to pollutants will help determine the most suitable product that can withstand environmental stresses over time.

When selecting a polymeric surge arrester, several key factors must be considered to ensure optimal protection for your electrical systems. First and foremost, understanding the application environment is essential. Polymeric surge arresters are designed to work in various conditions, including outdoor and indoor settings.

Evaluating the temperature range, humidity, and potential exposure to pollutants will help determine the most suitable product that can withstand environmental stresses over time.

Another critical factor is the voltage rating of the surge arrester. It should align with the maximum continuous operating voltage of your electrical system to guarantee reliable performance. Additionally, assessing the energy absorption capacity is vital; this measurement indicates the device's ability to handle transient surges effectively without malfunction. Finally, consider the manufacturer's reputation and warranty options. A reliable brand often ensures product quality and performance, providing peace of mind and long-term reliability for your surge protection needs.

When selecting the right polymeric surge arrester for your needs, it's essential to understand the different types available in the market.

Polymer-housed surge arresters are increasingly popular due to their lightweight and high insulating properties. According to industry reports, these devices can significantly reduce the risk of equipment damage caused by voltage surges, making them ideal for protecting critical infrastructure like power plants and substations.

Polymer-housed surge arresters are increasingly popular due to their lightweight and high insulating properties. According to industry reports, these devices can significantly reduce the risk of equipment damage caused by voltage surges, making them ideal for protecting critical infrastructure like power plants and substations.

Recent advancements in the manufacturing of polymeric surge arresters have led to increased production capabilities, allowing for more tailored solutions to specific applications. For instance, recent announcements highlight that major manufacturers are ramping up production to meet growing demand, especially in regions prone to electrical storms and other surge-inducing phenomena. By thoroughly evaluating the performance characteristics, such as insulation strength and response time, users can ensure they select the most suitable product for their unique environments and operational requirements.

Additionally, considerations about environmental factors and maintenance needs should not be overlooked. Certain polymeric surge arresters offer enhanced durability and longer service life, which translates into lower long-term costs. As the industry continues to evolve, staying informed about the latest innovations and market trends will empower users to make educated decisions on the right polymeric surge arresters for their specific applications.

When selecting a polymeric surge arrester, it is crucial to evaluate the performance specifications that determine its effectiveness and reliability in protecting electrical systems. Recent studies have highlighted the significance of the electric field distribution along insulator surfaces, which can be influenced by the integration of ZnO microvaristors. This optimization can lead to a more uniform electric field, reducing the likelihood of insulation failure and enhancing the longevity and efficiency of the surge arrester.

Further comparisons of metal oxide surge arresters (MOSAs) indicate they remain a top choice for mitigating overvoltages caused by lightning and switching surges in power distribution networks. Industry reports suggest that MOSAs exhibit superior response times and energy absorption capabilities compared to traditional arresters, with performance metrics demonstrating a reduction in failure rates by up to 50% when properly implemented. These characteristics underscore the importance of thorough performance evaluation, including voltage ratings and energy handling capabilities, when selecting the appropriate polymeric surge arrester for a specific application.

When selecting a polymeric surge arrester, understanding maintenance and longevity is crucial for ensuring optimal performance and reliability. Regular inspection is essential; inspect the arrester for any signs of physical damage, dirt accumulation, or weathering due to environmental factors. Keeping the arrester clean and free from contaminants not only helps maintain its functionality but also extends its lifespan. Incorporate a proactive maintenance schedule to identify potential issues before they escalate.

Moreover, the installation environment plays a significant role in the durability of your polymeric surge arrester. Ensure that it is installed in an area with adequate ventilation and protection from harsh weather conditions. Consider using surge arresters that are specifically designed to withstand local climate conditions. Additionally, it's essential to educate your maintenance team on proper handling and operational protocols, as this knowledge can drastically reduce the risk of premature failure. By prioritizing maintenance and choosing the right conditions for installation, you can maximize the longevity of your polymeric surge arresters and maintain system integrity.