-

Home

-

About Us

-

Products

-

News

-

Blog

-

Contact Us

Leave Your Message

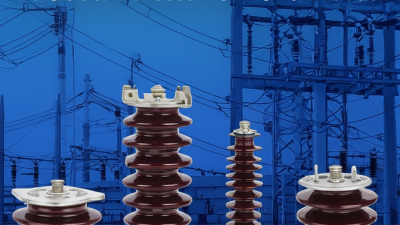

In today's industrial landscape, the demand for reliable insulation materials is crucial. Silicone Rubber Insulators stand out for their durability and resistance to extreme temperatures. According to a 2022 market report, the silicone rubber segment is projected to grow by 5.4% annually. This growth is driven by the increasing need for electrical insulation in various applications.

Silicone Rubber Insulators offer unique benefits, such as flexibility and long-term resilience. They can operate within a wide temperature range, making them suitable for many environments. However, some manufacturers still face challenges with production quality. This inconsistency can lead to reduced performance, raising concerns for users in critical applications.

The right Silicone Rubber Insulator can significantly improve performance and reliability. Yet, not all products meet the same standards. Consumers must navigate a crowded market, balancing cost and quality. With various options available, making an informed choice is essential to ensure safety and efficiency.

Silicone rubber insulators are essential components in various industries. They provide electrical insulation, thermal stability, and mechanical durability. These insulators are resistant to extreme temperatures and harsh environmental conditions, making them suitable for outdoor applications and indoor environments alike.

In electrical applications, silicone rubber insulators help prevent short circuits and equipment failures. They are used in connectors, transformers, and power supply systems. The flexibility of silicone rubber also allows for unique designs and configurations. This adaptability can lead to different challenges in manufacturing and installation.

While silicone rubber insulators are effective, they are not without limitations. Their performance can degrade under certain conditions. For example, exposure to UV light may weaken the material over time. It's crucial to evaluate their usage based on the specific environment. Consideration is needed for both performance and longevity to ensure reliability in critical applications.

Selecting the right silicone rubber insulator is essential for optimal performance. Key factors include temperature resistance, electrical insulation properties, and mechanical strength. A report by Research and Markets revealed that the silicone rubber market will grow at a CAGR of 5.2% through 2026. This growth reflects the increasing demand for high-quality insulators in various industries.

Temperature tolerance is crucial. Different applications require different thermal ranges. For example, some insulators can withstand up to 300°C, while others operate effectively around 200°C. Make sure to assess your application’s specific temperature needs to avoid premature failures. Electrical insulation is another critical aspect. A good insulator should have a high dielectric strength, typically around 20 kV/mm or higher, depending on application requirements. Many buyers overlook this feature, leading to significant safety risks.

Mechanical strength matters, too. Insulators must withstand physical stress without cracking or degrading over time. According to industry standards, the tensile strength of silicone rubber should be over 5 MPa to ensure durability. However, not all options meet these benchmarks. It’s essential to examine product specifications closely. Balancing these factors can be challenging. Sometimes, a higher price tag doesn’t guarantee better performance. Careful evaluation is necessary to find the right balance for your specific needs.

When it comes to selecting silicone rubber insulators, understanding your specific needs is crucial. Different applications call for different properties. For example, high temperature resistance is vital in some industrial settings, while flexibility might be key in automotive uses. The right product can not only enhance safety but also improve efficiency.

Tips: Always check the temperature ratings. Not all silicone insulators perform similarly under heat. Consider environmental factors too. Outdoor applications may require insulators that resist UV damage.

In various projects, you might find that one insulator performs excellently in a lab test but fails during real-world use. It’s essential to examine your operational environment closely. Don’t hesitate to test multiple options. Feedback from practical applications often uncovers unexpected benefits or limitations.

Tips: Look into user reviews for insights. Real-world experiences can highlight issues that specifications might not cover. Pay attention to durability and long-term performance.

| Product Name | Temperature Rating (°C) | Color | Thickness (mm) | User Rating |

|---|---|---|---|---|

| High Temp Silicone Sheet | -60 to 260 | Red | 2 | 4.7 |

| Silicone Rubber Mat | -50 to 230 | Black | 3 | 4.5 |

| Industrial Silicone Insulator | -40 to 200 | Gray | 5 | 4.6 |

| Silicone Insulating Ring | -60 to 180 | Transparent | 1 | 4.8 |

| Heavy Duty Silicone Pad | -10 to 300 | Blue | 10 | 4.9 |

| Flexible Silicone Tube | -50 to 220 | Red | 2 | 4.5 |

| Silicone Gasket Material | -20 to 250 | Black | 3 | 4.6 |

| Food Grade Silicone Sheet | -40 to 250 | White | 4 | 4.7 |

| Silicone Electric Insulator | -40 to 220 | Light Blue | 6 | 4.8 |

| High Density Silicone Block | -50 to 270 | Black | 8 | 5.0 |

When considering silicone rubber insulators, it’s important to analyze their features and benefits. These materials are highly resistant to temperature variations. They can endure extreme heat and cold without losing their properties. This makes them suitable for diverse environments. Their flexibility allows for easy installation across different applications.

Durability is another critical advantage. Silicone rubber insulators can withstand weathering and aging. They resist sunlight, ozone, and other harsh conditions. However, not all silicone insulators are created equal. Some might not perform well in specific situations. Thus, assessing individual needs is key.

The insulation properties are also significant. Silicone rubber can effectively prevent electrical conductivity. This makes it ideal for electrical applications. Yet, users must consider their specific requirements. It’s vital to ensure compatibility with intended uses. The right choice balances performance and cost. Finding the perfect silicone rubber insulator requires thorough research and careful selection.

Maintaining silicone rubber insulators is crucial for their longevity. Regular inspections help identify wear, cracks, or any signs of deterioration. If you notice any issues, it’s best to replace them before they cause problems. Dirt and grime can accumulate over time, affecting performance. Clean them frequently using a mild detergent and water. Avoid harsh chemicals; they can degrade silicone.

Storage also plays a role in the care of silicone insulators. Keep them in a cool, dry place away from direct sunlight. Excessive heat can alter their properties. Be cautious about bending or twisting these insulators, as this can cause permanent deformation. While silicone is flexible, it does have limits.

Always check compatibility with other materials. Some combinations may lead to unexpected reactions. Regularly replace insulators after a certain period or usage cycles to ensure safety. While silicone rubber is durable, it is not indestructible. Neglecting maintenance can lead to unexpected failures. Keep records of inspections and replacements. This simple practice can help identify patterns over time.