-

Home

-

About Us

-

Products

-

News

-

Blog

-

Contact Us

Leave Your Message

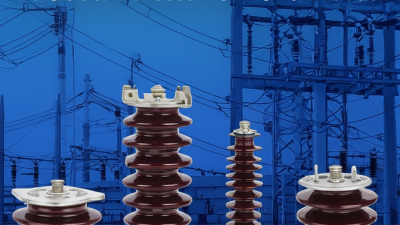

In the realm of industrial safety and efficiency, the role of high-quality materials cannot be overstated. Silicone Rubber Arresters, known for their durability and flexibility, are increasingly becoming essential components in various applications, from electronics to automotive industries. According to a report by MarketsandMarkets, the global silicone market is projected to reach USD 25.8 billion by 2026, exhibiting a compound annual growth rate (CAGR) of 4.4% over the forecast period. This surge underscores the demand for robust products such as Silicone Rubber Arresters, which are critical for ensuring performance under extreme conditions. With the world's leading factories in China now poised to offer superior manufacturing capabilities, choosing the right Silicone Rubber Arrester tailored to specific industrial needs has never been more vital. Understanding the key characteristics and benefits of these materials can enhance operational efficiency and safety, prompting stakeholders to make informed decisions in their procurement strategies.

When selecting silicone rubber arresters for industrial applications, understanding the various types and their key features is essential. Silicone rubber is a synthetic polymer characterized by its heat resistance, flexibility, and durability, making it suitable for diverse applications across various sectors. The global automotive silicone market, valued at USD 2.4 billion in 2023, demonstrates the material's increasing relevance, with a projected growth to USD 3.4 billion by 2028, reflecting a compound annual growth rate (CAGR) of 7.3%.

Among the different types of silicone rubber arresters, key features such as temperature stability, chemical resistance, and electrical insulation properties play a crucial role in their performance. Industrial users must also consider specific applications, such as vibration damping, sealing, and electrical insulation. Understanding the unique properties of silicone rubber enables manufacturers to select products that not only meet their operational demands but also enhance the longevity and reliability of their equipment. Consequently, the right silicone rubber arrester can lead to optimized performance while contributing to cost efficiency over time.

When selecting a silicone rubber arrester for industrial applications, understanding its durability and performance is of utmost importance. Silicone rubber is well-regarded for its excellent resistance to extreme temperatures and environmental hazards, making it an ideal material for arresters used in challenging conditions. Its ability to maintain integrity in high or low temperatures helps ensure that the arrester can provide consistent protection over time, thus reducing the risk of failures that could lead to costly downtime in industrial operations.

Moreover, the performance characteristics of silicone rubber arresters can greatly influence their effectiveness in various applications. The material's inherent flexibility allows for efficient energy absorption, which is crucial in mitigating the impact from surges or shocks. Additionally, the chemical stability of silicone rubber ensures that the arrester remains unaffected by exposure to oils, solvents, and other harsh substances commonly found in industrial environments. By carefully considering these durability and performance factors, industries can make informed decisions when choosing the right silicone rubber arrester to meet their specific needs.

When selecting silicone rubber arresters for industrial applications, several key factors must be taken into account to ensure optimal performance and safety. First and foremost, consider the operating conditions such as temperature range, chemical exposure, and mechanical stress. Silicone rubber is known for its resilience under extreme temperatures, but different grades may offer varying resistance to specific chemicals, which is critical in industries like food processing or pharmaceuticals. Understanding these environmental factors will guide you in choosing a product that meets your specific operational requirements.

Another crucial aspect is the physical properties of the silicone rubber arresters, including tensile strength, tear resistance, and flexibility. Assessing the load capacities and the intended use of the arresters will help determine the right specifications. For instance, if the application involves high levels of stress or dynamic movements, opting for a silicone rubber that exhibits high tensile strength and superior tear resistance is vital. Additionally, consider the compliance standards relevant to your industry, as selecting products that meet or exceed these criteria not only ensures safety but also contributes to a more efficient operational process.

This chart illustrates the importance of various factors to consider when selecting silicone rubber arresters for industrial applications. Each factor is rated on a scale from 1 to 10, indicating its significance in the selection process.

When comparing silicone rubber arresters to traditional options, one must consider several critical performance metrics. According to a recent industry report by TechSci Research, silicone rubber alternatives typically show an impressive thermal resistance range of -60°C to 200°C, significantly outperforming conventional materials, which often degrade under extreme temperatures. This quality not only enhances their durability but also reduces maintenance costs in industrial settings, where equipment failures can lead to costly downtimes.

Moreover, a study published in the Journal of Applied Polymer Science highlights the superior electrical insulating properties of silicone rubber arresters. They possess a dielectric strength exceeding 20 kV/mm, compared to traditional materials that often average around 15 kV/mm. This elevated electrical performance ensures better safety and reliability in high-voltage applications, solidifying silicone rubber's position as a preferable choice for industries focused on minimizing electrical hazards while maximizing operational efficiency. By investing in these advanced materials, companies can expect not only improved performance but also long-term cost savings through reduced failures and increased system uptime.

When it comes to ensuring optimal performance of silicone rubber arresters, regular maintenance is key. These essential components often face harsh conditions, which can lead to wear and tear over time. Begin by conducting routine visual inspections to check for any signs of cracking, wear, or damage. Regularly assessing the condition of the arresters will help identify potential issues before they escalate, thus prolonging their lifespan and maintaining their effectiveness.

Cleaning silicone rubber arresters is another crucial maintenance step. Accumulated dust, grease, or other contaminants can hinder their performance. Utilize a mild solvent or soap solution, avoiding harsh chemicals that could degrade the material. After cleaning, ensure that the arresters are thoroughly dried before reinstallation. Additionally, monitor the operating environment—extreme temperatures or exposure to chemicals can affect the integrity of the silicone. By implementing these maintenance tips, you can enhance the reliability and efficiency of your silicone rubber arresters, ensuring they operate efficiently for your industrial needs.

| Feature | Description | Maintenance Tips |

|---|---|---|

| Material Type | Silicone rubber offers excellent heat and chemical resistance. | Regularly inspect for signs of wear or degradation. |

| Temperature Range | Can withstand temperatures from -60°C to 200°C. | Ensure the application stays within the specified temperature range. |

| Shore Hardness | Commonly available in 30A to 60A hardness levels. | Test softness regularly to ensure it meets operational requirements. |

| Electrical Properties | Good dielectric strength and insulation properties. | Check for conductivity and insulation failure periodically. |

| Chemical Resistance | Resists oils, solvents, and ozone exposure. | Keep the arrested surfaces clean and free of contaminants. |