-

Home

-

About Us

-

Products

-

News

-

Blog

-

Contact Us

Leave Your Message

In industrial applications, protecting electrical systems is crucial. The choice of arrester affects overall system performance and longevity. The Silicone Rubber Arrester is emerging as a superior option. According to recent data, its use can reduce maintenance costs by nearly 30%. This material demonstrates exceptional durability and stability even in extreme environmental conditions.

Silicone Rubber Arresters offer excellent insulation properties. They withstand high voltages and temperatures effectively. This resilience contributes to reliable operation over time. Furthermore, a study by industry experts revealed that these arresters can significantly extend equipment lifespan. However, some manufacturers still overlook the importance of selecting the right material. This oversight can result in frequent replacements and increased operational costs.

Market analysis suggests that the demand for Silicone Rubber Arresters is on the rise. In regions prone to weather extremes, their effectiveness is particularly pronounced. Yet, not all arresters in the market meet the desired specifications. Users must ensure they select high-quality options to maximize benefits. The future of power protection lies in the continued adoption of advanced materials, making careful selection essential.

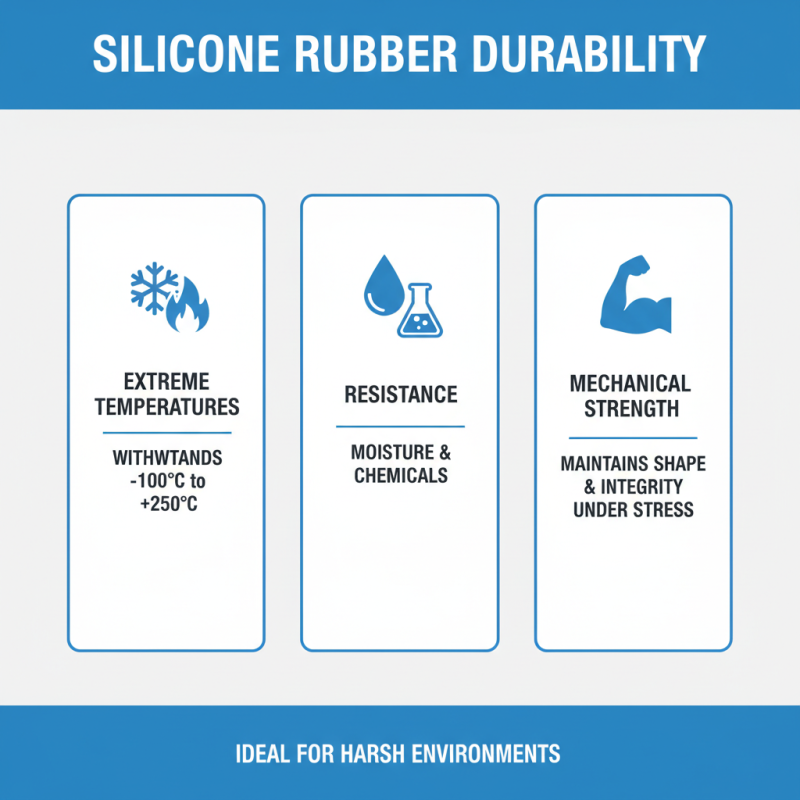

Silicone rubber arresters offer several advantages in electrical systems. They provide excellent insulation and resistance to heat. This makes them ideal for high-performance setups. The silicone material can withstand extreme temperatures without degrading. In addition, it does not crack or become brittle over time. This durability extends the lifespan of electrical components significantly.

Another benefit is the flexibility of silicone rubber arresters. They easily adapt to various environments and conditions. This adaptability helps in maintaining optimal performance across different electrical systems. However, installing these devices requires careful consideration. Improper installation can lead to failure or inefficient operation. It's crucial to assess your specific needs before making a choice.

Silicone rubber arresters also excel in protecting against moisture and dust. Their robust structure minimizes the risk of electrical failures due to environmental factors. Still, ensuring that the arresters remain clean and intact is essential for their effectiveness. Regular checks can mitigate potential issues. While these arresters are effective, understanding their limitations is equally important.

When considering arresters, silicone rubber stands out against traditional materials like ceramics or metal. Silicone rubber is incredibly flexible. It can tolerate extreme temperatures, which might damage other materials. This flexibility also allows for better energy absorption when a surge occurs. The material’s high resistance to UV light is another advantage. It won't break down as quickly when exposed to sunlight.

Traditional materials often suffer in harsher conditions. Metals can corrode, while ceramics may crack under pressure. These failures can lead to increased risks in systems. Silicone rubber, on the other hand, maintains its integrity over time. However, it can be more susceptible to certain chemical exposures. This aspect requires careful consideration during material selection.

Additionally, installation with silicone rubber arresters tends to be simpler. The lightweight nature allows for easier handling. But manufacturers may face challenges during production. Ensuring consistent quality in large batches can sometimes be tricky. Users must remain mindful of these factors when deciding on the best materials for their needs.

Silicone rubber is renowned for its durability in harsh environments. It withstands extreme temperatures, from freezing cold to scorching heat. This material is also resistant to moisture and chemicals, which makes it ideal for various applications. It performs well under stress, maintaining its shape and integrity over time.

When choosing silicone rubber for your arrester, consider its electrical resistance. Silicone has excellent insulating properties, ensuring safety in high-voltage scenarios. However, not all silicone rubber is created equal. Some formulations may lack the necessary toughness. It’s crucial to assess the specific requirements of your environment before making a selection.

**Tip:** Always check the temperature and chemical tolerance of silicone rubber. Use in environments exceeding these limits could lead to failure.

Balancing performance and cost is important. While high-quality silicone offers superior performance, it may come with a higher price tag. Evaluate your project needs carefully. Sometimes, opting for a less expensive variant might sacrifice longevity.

**Tip:** Consider potential trade-offs when selecting materials. A cheaper option can lead to higher maintenance costs down the line. Always think about the long-term implications of your choices.

Installing silicone rubber arresters requires careful planning. Proper installation ensures optimal performance and longevity. Experts suggest that a well-installed arrester can improve energy efficiency by up to 30%. This data highlights the importance of getting the installation right the first time. During installation, it is vital to ensure the seal is precise. A small gap can lead to significant energy loss.

Maintenance is another crucial aspect. Regular inspections help identify wear and tear early. Silicone rubber has impressive durability, often lasting over a decade under proper usage. However, routine checks are necessary to confirm it remains effective. A study indicates that 25% of failures occur due to neglect in maintenance. Users should monitor for cracks, discoloration, or any signs of wear. Keeping records of inspections can streamline this process.

Incorporating a maintenance schedule can greatly enhance the life of silicone rubber arresters. It’s essential to have a plan tailored to specific operational conditions. Monitoring environmental factors like temperature and humidity can lead to better performance. Learning from past mistakes can help in refining maintenance routines. Investing time in these guidelines may prevent costly downtime in the future.

Silicone rubber arresters offer impressive cost-effectiveness and longevity in various applications. According to industry reports, these materials can last up to 10 years longer than traditional alternatives. This extended lifespan translates into reduced replacement costs and less downtime for maintenance. Many industries are now recognizing the long-term savings provided by silicone rubber solutions.

Moreover, silicone rubber arresters feature exceptional resilience. They withstand extreme temperatures, ranging from -40°F to 400°F. This flexibility in harsh environments makes them ideal for diverse applications, such as electrical systems and industrial equipment. In fact, some studies indicate a performance efficiency of over 90% even under challenging conditions.

Despite these benefits, not every installation is flawless. Misapplications can lead to premature wear or failure. Users must understand the specific requirements of their applications. Choosing the right silicone rubber arrester requires careful consideration and sometimes trial and error. The goal is to strike a balance between performance and cost, ensuring that the investment in silicone rubber truly delivers optimal results.

| Feature | Silicone Rubber Arresters | Traditional Materials |

|---|---|---|

| Cost-Effectiveness | High initial investment but lower long-term maintenance costs | Lower initial costs but higher long-term maintenance |

| Longevity | Typically last 10-20 years | Usually last 5-10 years |

| Temperature Resistance | Excellent resistance from -50°C to 250°C | Limited resistance, around -20°C to 100°C |

| Chemical Resistance | Highly resistant to oils, acids, and solvents | Limited chemical resistance, can degrade over time |

| Environmental Impact | Recyclable and environmentally friendly | Non-recyclable and can harm the environment |