-

Home

-

About Us

-

Products

-

News

-

Blog

-

Contact Us

Leave Your Message

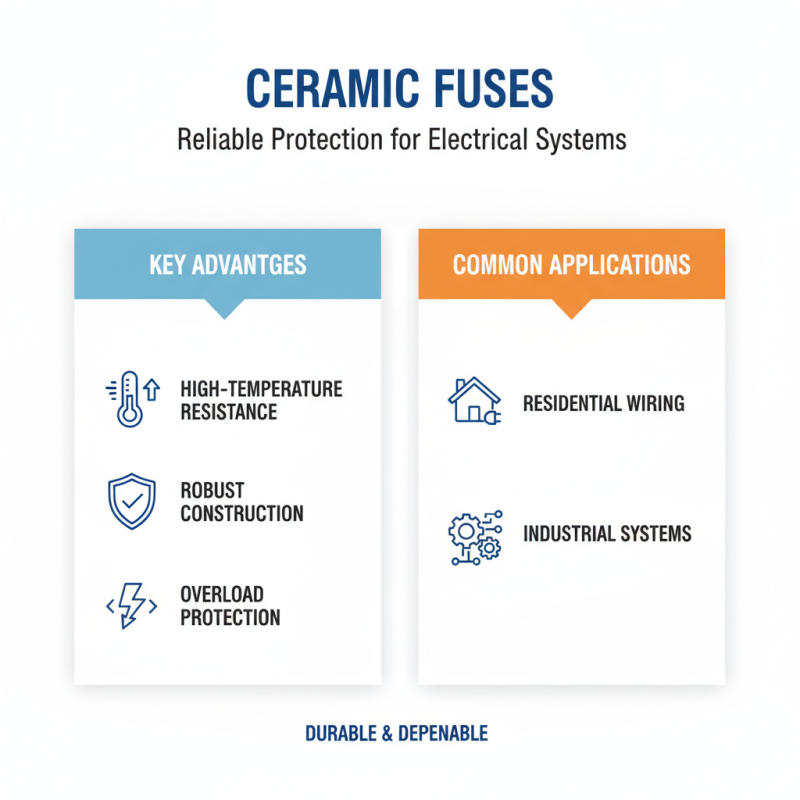

In today's electrical industry, the importance of reliable safety devices cannot be overstated. Ceramic fuses are gaining recognition for their superior performance and safety features. According to a recent report by the Electrical Safety Foundation International, over 30% of electrical fires result from faulty fuses. This alarming statistic highlights the need for effective protection in all electrical applications.

Expert John Smith, a leading authority on fuse technology, emphasizes the significance of ceramic fuses, stating, "Ceramic fuses provide unparalleled reliability and current interruption." Their design allows for higher breaking capacities, making them ideal for challenging environments. Unlike traditional glass fuses, ceramic fuses are less likely to shatter under extreme conditions. However, their initial cost can be higher, prompting some uncertainty among consumers.

Despite potential drawbacks, opting for ceramic fuses can enhance safety and efficiency. Organizations must consider long-term benefits over upfront costs. Investing in quality fuses leads to sustainable performance and greater peace of mind. In an industry focused on minimizing risks, ceramic fuses stand out as a dependable choice for electrical needs.

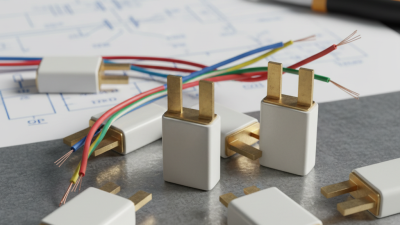

Ceramic fuses provide distinct advantages for various electrical applications. Unlike traditional glass fuses, ceramic fuses are more robust and resistant to high temperatures. They can handle overloads better, which prevents damage to electrical circuits. The ceramic material allows for safer operation in extreme conditions.

Moreover, ceramic fuses have better interrupting ratings. This means they can break circuits quickly in case of faults, reducing risks. Their construction also minimizes the chances of glass shards in the event of a failure. A potential downside is that ceramic fuses can be bulkier than other types. This may limit their use in compact spaces.

Additionally, while they boast longevity, improper installation can negate their benefits. It's essential to choose the right rating. A mismatch can lead to either nuisance blowing or insufficient protection. Overall, the characteristics of ceramic fuses often outweigh these challenges.

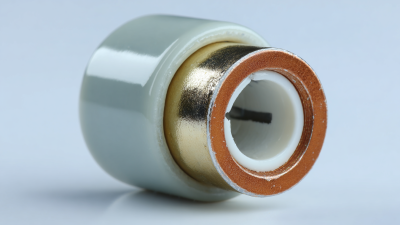

Ceramic fuses are a popular choice for electrical systems. They play a crucial role in protecting circuits from overloads and short circuits. Understanding their construction helps to appreciate their functionality. Ceramic fuses are made from high-quality ceramic material, making them durable and heat resistant. This is vital in preventing breakage during operation.

The inner components typically include a thin wire that melts under excessive current. This melting interrupts the electrical flow, protecting other devices. The external casing ensures maximum safety. However, not every type of ceramic fuse is suitable for all applications. Users must reflect on their specific needs. Choosing the wrong fuse can lead to inefficient performance. Over time, the need for regular checks exists.

Functionality varies between different fuse types, but ceramic fuses are versatile. They can handle various voltage levels and current ratings. With proper installation, they provide reliable service. Nonetheless, it’s easy to overlook regular maintenance. Ignoring this can lead to risks that affect overall safety. Balancing performance and safety is key in every electrical setup.

Ceramic fuses are widely used in various electrical systems. They offer distinct advantages in many applications. In residential wiring, they provide reliable protection against overloads. Their robust construction withstands high temperatures, making them suitable for home environments.

In industrial settings, ceramic fuses excel in protecting heavy machinery. They can handle large current loads without failure. These fuses also reduce downtime due to their durability. However, users should occasionally review fuse ratings to ensure compatibility. A mismatch could lead to inadequate protection.

In automotive applications, ceramic fuses add a layer of safety. They prevent shorts and protect sensitive electronics. Yet, it's crucial to install them correctly. Improper installation might cause dangerous situations. Regular checks can help avoid potential issues with performance and safety.

When it comes to fuses, ceramic and glass varieties each have distinct characteristics. Ceramic fuses feature a robust construction that offers better heat resistance. This quality allows them to handle higher electrical loads without failure. In contrast, glass fuses are more fragile and can shatter upon impact. Their see-through design is helpful for quick visual checks. However, this transparency can lead to unintended risks if broken.

Ceramic fuses often have a higher breaking capacity than glass. This means they can safely interrupt larger fault currents. Users may face a delay when replacing glass fuses, as it can be harder to find the right size. Meanwhile, ceramic fuses provide durability and consistent performance over time. Yet, some might find them pricier initially, which can deter budget-conscious buyers.

Deciding between these two options requires thoughtful consideration. Consider the specific electrical needs and environment. Ceramic fuses excel in harsh conditions, while glass may suffice for light-duty applications. Each type has its benefits and drawbacks, requiring users to reflect on their particular requirements.

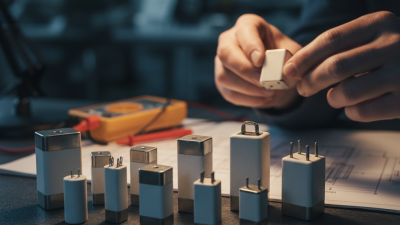

Ceramic fuses are popular for various electrical applications due to their reliability. When selecting ceramic fuses, it's crucial to consider several factors. One important aspect is the fuse rating. A proper rating ensures that the fuse will operate effectively during overload situations. According to industry reports, around 30% of fuse-related failures result from incorrect ratings.

Another key factor is the fuse's voltage and current capacity. Ceramic fuses typically have high interrupting ratings. This means they can safely stop excessive current without causing damage. Some studies indicate that using the right fuse can reduce equipment failure rates by up to 50%. However, users often overlook these specifications, leading to inefficient performance.

Additionally, installation methods matter. Improper installation can lead to frequent fuse blowouts. Research shows that about 15% of fuse failures occur due to installation errors. It's essential to follow guidelines and double-check connections. Even a small oversight can compromise safety and efficiency. Balancing these considerations can be challenging, but they are key to maximizing the performance of ceramic fuses.