-

Home

-

About Us

-

Products

-

News

-

Blog

-

Contact Us

Leave Your Message

Choosing the right Cooper Power Fuses is crucial for any electrical system. According to industry expert John Smith, "The right fuse can be the difference between a well-functioning system and catastrophic failure." This highlights the importance of understanding your specific electrical needs.

Cooper Power Fuses come in various types and ratings. Each type serves unique purposes. Not all fuses are created equal—what works for one system may not work for another. Selecting an inappropriate fuse could lead to frequent outages or damage to equipment.

Consider the load capacity and voltage ratings when choosing Cooper Power Fuses. This isn't always straightforward, as many factors influence these decisions. Sometimes, we overlook the significance of environmental factors too. Humidity, temperature, and installation conditions greatly affect performance. Understanding these details is essential for optimal safety and reliability.

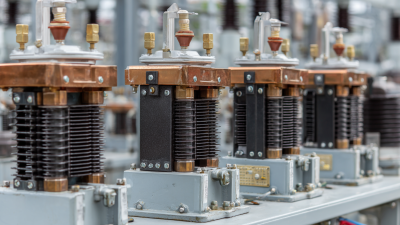

Cooper power fuses play a crucial role in electrical systems. They protect circuits from overloads and short circuits. Understanding their applications is vital for anyone working with electricity.

These fuses come in different ratings. The right choice depends on your specific needs. Consider factors like voltage, current, and installation environment. If the wrong fuse is selected, it can lead to inadequate protection. This can cause equipment damage and safety hazards.

Installation of fuses should be done with care. Proper placement is key. Ensure that accessibility for maintenance is also considered. Different types of fuses offer unique advantages. Some are designed for indoor use, while others withstand harsher outdoor conditions. Think about where it will be used. Not all fuses are created equal, and mistakes can be costly.

| Fuse Type | Voltage Rating (kV) | Current Rating (A) | Application |

|---|---|---|---|

| Distribution Fuses | 15 kV | 100 A | Secondary Voltage Protection |

| Substation Fuses | 34.5 kV | 200 A | Transformer Protection |

| Motor Fuses | 600 V | 30 A | Motor Circuit Protection |

| Renewable Energy Fuses | 1 kV | 50 A | Solar PV Systems |

When selecting fuses, assessing your electrical needs is crucial. Consider your system’s voltage and current ratings. These elements help determine the appropriate fuse size. Too small a fuse can lead to frequent blowouts. Too large a fuse might not protect your equipment effectively.

Next, think about the environment where the fuse will be used. Is it exposed to moisture or extreme temperatures? This factor can affect performance and lifespan. Opt for a fuse designed for harsh conditions if necessary. It’s essential to balance protection and functionality.

Lastly, evaluate your future requirements. Are you planning to expand your electrical system? If so, it might be wise to choose fuses that can accommodate a higher load. Remember, flexibility can save you from frequent replacements down the road. Regularly review your choices. Adjusting based on changes in your system is vital for optimal performance.

This bar chart represents the electrical current ratings for various types of fuses commonly used in electrical systems. It helps in identifying the most suitable fuse based on your specific electrical requirements.

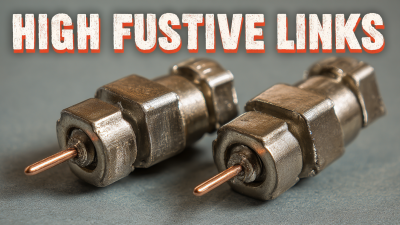

When selecting Cooper Power fuses, understanding the variety available is crucial. There are different types of fuses, such as current-limiting and dual-element fuses. Current-limiting fuses act fast to eliminate excess current, protecting equipment from damage. Dual-element fuses offer a time-delay feature, allowing temporary overloads without tripping. This functionality can be beneficial in industrial settings where equipment may experience short spikes in demand.

Reliable studies reveal that approximately 30% of electrical equipment failures are due to inadequate fuse protection. This statistic highlights the importance of choosing the right fuse type. For instance, in environments with frequent surges, dual-element fuses can prove more effective. However, choosing the wrong type can lead to costly downtime. A survey by industry experts indicates that 25% of businesses do not assess their fuse needs regularly, which can result in improper protection.

Additionally, fuse ratings can vary significantly. Some applications may require high-voltage fuses, while others function effectively with lower ratings. Not all fuses are created equal, and selecting the incorrect one can lead to operational difficulties. It’s essential to evaluate operational conditions and load requirements closely. Given these discrepancies, users should weigh their choices carefully and avoid simply defaulting to standard options.

When choosing the right fuse for your electrical system, several factors are crucial. Voltage rating is important. Ensure the fuse can handle the system's voltage without risk. Consider the current rating as well. The fuse should be rated slightly above the expected load. This prevents nuisance blowing but protects equipment effectively.

Response time is another aspect to think about. Fast-acting fuses react quickly against surges, while time-delay fuses can endure brief overloads. Knowing your system’s operational characteristics will guide this decision. Additionally, the environment matters, too. Some fuses are better suited for wet or corrosive conditions. Make sure to select one that matches your installation's specifics.

Lastly, don't overlook sizing. A fuse that is too small can trip frequently. One that is too large may not protect adequately. It’s a delicate balance. Performing a careful assessment will help avoid costly mistakes later. It's essential to regularly review your choices, as needs may change over time.

When it comes to installing power fuses, safety is paramount. Ensure that the area is clear of any moisture. This can prevent electrical accidents. Wear gloves to protect your hands. Before installation, read all guidelines carefully. Understanding the specifications is crucial for proper setup. Use tools that are rated for electrical work. If tools are rusty or damaged, consider replacing them. This can save a lot of trouble later.

Maintenance of power fuses is often overlooked. Regular checks can prevent failures. Inspect the fuses for signs of wear. Look for discoloration or any physical damage. These could indicate underlying issues. Ensure connections are tight and corrosion-free. If you find any, clean thoroughly. Be mindful that over time, fuses can degrade. Accumulated dirt can also be a potential risk. Keeping the area clean assists overall performance.

Safety during use can never be stressed enough. Educating all users on correct procedures is vital. Always follow safety protocols when handling fuses. Use a circuit tester to confirm that the power is off before touching any component. Mistakes happen; don’t rush through processes. Taking the time to do things right can prevent dangerous mishaps. Consider documenting all inspections and maintenance done. This helps track the performance and any recurring issues.