-

Home

-

About Us

-

Products

-

News

-

Blog

-

Contact Us

Leave Your Message

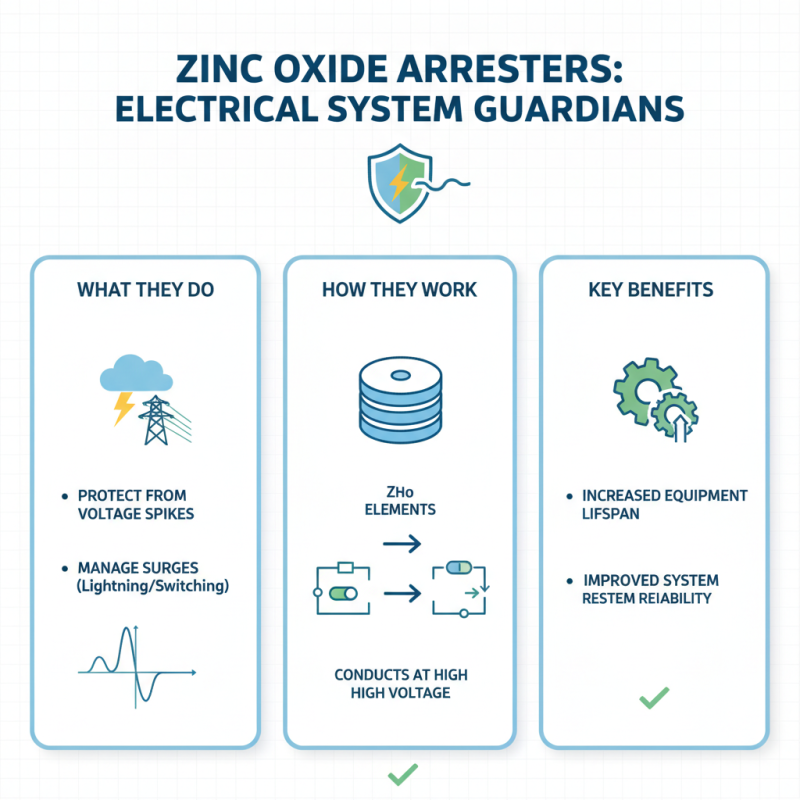

Choosing the right Zinc Oxide Arrester is crucial for your device’s safety. A suitable arrester protects against voltage surges. These devices help in maintaining the efficiency of electrical systems.

When looking for a Zinc Oxide Arrester, consider your specific needs. Each application has its challenges. You might face issues like inadequate ratings or compatibility problems. Take the time to research different brands and models available in the market. Sometimes, the cheaper option might not perform as expected. Pay attention to user reviews and recommendations.

Make sure you understand the technical specifications required for your system. Not all Zinc Oxide Arrester models are alike. Some may offer features that better suit your needs, while others could fall short. Reflect on the feedback you find. It might lead you towards a better choice. Selecting an arrester requires careful consideration and informed decisions.

Zinc oxide arresters play a crucial role in protecting electrical systems from voltage spikes. These devices manage surges caused by lightning or switching events. Understanding their functionality is essential for proper selection and installation.

Zinc oxide materials offer superior protection. They can absorb and dissipate excess energy efficiently. This helps prevent damage to sensitive equipment. When choosing an arrester, evaluate the voltage rating and energy absorption capacity. These factors determine their effectiveness in various applications.

Installation is equally important. Proper grounding ensures optimal performance. Inadequate grounding can lead to failures. Regular checks on the system can help identify potential issues. Maintenance of arresters is often overlooked, yet it is vital. A neglected arrester could compromise safety and functionality. Be mindful of these details when selecting a zinc oxide arrester.

When selecting a zinc oxide arrester, certain specifications are crucial. Consider the voltage rating. It must match your system requirements. A mismatch can lead to performance failures. Look closely at the energy absorption capability. This value indicates how much energy is handled during a fault. Higher ratings often mean better protection.

Another key specification is the insulation level. This pertains to the maximum system voltage the arrester can manage without breaking down. Assess the installation environment. Humidity and temperature can affect performance. Additionally, check the response time of the arrester. A quicker response can prevent damage effectively.

Consider the physical design as well. Size and weight matter for installation ease. Sometimes, larger arresters may not fit in confined spaces. Reflect on these details carefully. Each choice impacts safety and efficiency. Make informed decisions, as even minor oversights can lead to significant issues later on. Think beyond the basics to ensure you choose wisely.

When selecting a zinc oxide arrester, voltage rating and surge current capacity are crucial. The voltage rating indicates the maximum sustained voltage the device can handle. Generally, ratings vary from 3kV to 12kV. A unit with an insufficient rating can lead to frequent failures. This data aligns with the National Electrical Manufacturers Association (NEMA), which emphasizes that the correct rating protects your equipment effectively.

Surge current capacity is equally important. This defines how much surge current the arrester can divert during a high-voltage event. Devices typically rate between 10kA to 100kA. A lower capacity might offer temporary protection, but it could endanger sensitive electronics. The Institute of Electrical and Electronics Engineers (IEEE) suggests that checking the specific application is necessary. Optimal protection requires understanding both the anticipated surge levels and the system's specifications.

Choosing the right arrester is not just about specifications. It involves a thorough understanding of your environment and needs. There’s often a tendency to overlook real conditions and focus only on numbers. This can lead to mismatched ratings and unexpected failures. A holistic assessment is crucial for effective surge protection.

This bar chart represents the voltage ratings and surge current capacities of different zinc oxide arresters suitable for various applications.

When selecting a zinc oxide arrester, environmental conditions are essential. Think about the location. Is it urban or rural? Climates vary greatly. Humidity levels or temperature shifts can impact performance. In coastal areas, salt air is a concern. It causes corrosion.

Installation plans also play a role in your choice. Examine the mounting method. Will it be on a pole or a building? Assess the height. Taller installations may require units with higher ratings. Doing it right is vital. An improper choice can lead to failure. Monitor the area for potential hazards too. Nearby trees or buildings can interfere.

Take time to research the installation site. Environmental factors are often overlooked. Users can underestimate their impact on performance. Reflect on your specific needs. A tailored approach to selection can prevent issues later. Your attention to detail will yield better results.

When selecting a zinc oxide arrester, understanding manufacturer certifications and industry standards is crucial. Many products on the market claim to meet certain standards, but not all certifications have the same weight. The IEEE (Institute of Electrical and Electronics Engineers) and IEC (International Electrotechnical Commission) provide recognized frameworks for quality and safety. According to a recent industry report, over 30% of products failed to meet basic performance metrics during testing, highlighting the importance of trusted certifications.

Tips: Always ask for certification documents. Check if the arrester meets the IEC 60099-4 standard. This standard ensures that the arrester performs effectively under various conditions.

Moreover, look at the manufacturer’s track record. Experience matters. A company with a history of reliability tends to produce better products. However, not all long-standing firms have adapted to new technologies. Some may still rely on outdated practices, raising questions about their current quality.

Tips: Research reviews and industry feedback. Look for certifications that indicate continuous improvement and innovation. An arrester built on outdated concepts may leave you vulnerable to damaging surges.