-

Home

-

About Us

-

Products

-

News

-

Blog

-

Contact Us

Leave Your Message

Choosing the right Ceramic Fuse for electrical applications is a vital aspect of ensuring safety and efficiency in various systems. Ceramic fuses are designed to provide reliable overcurrent protection, making them essential components in both residential and industrial settings. According to a report by the International Electrotechnical Commission, the demand for efficient protective devices, including ceramic fuses, is expected to grow by 5% annually through 2025 due to increasing concerns over electrical safety and the expansion of global electrical infrastructure.

Choosing the right Ceramic Fuse for electrical applications is a vital aspect of ensuring safety and efficiency in various systems. Ceramic fuses are designed to provide reliable overcurrent protection, making them essential components in both residential and industrial settings. According to a report by the International Electrotechnical Commission, the demand for efficient protective devices, including ceramic fuses, is expected to grow by 5% annually through 2025 due to increasing concerns over electrical safety and the expansion of global electrical infrastructure.

When selecting a ceramic fuse, it’s important to consider factors such as voltage ratings, current ratings, and environmental conditions. A comprehensive understanding of these parameters can significantly influence the performance and longevity of electrical systems. The National Electrical Manufacturers Association emphasizes that improper selection of fuses can lead to catastrophic failures, highlighting the importance of adhering to standardized guidelines. As electrical systems become more complex, the role of ceramic fuses in safeguarding against overloads and short circuits has never been more critical. Therefore, knowing how to choose the appropriate ceramic fuse is essential for any electrical professional or DIY enthusiast looking to ensure optimal functionality and safety.

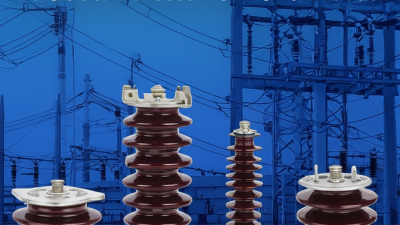

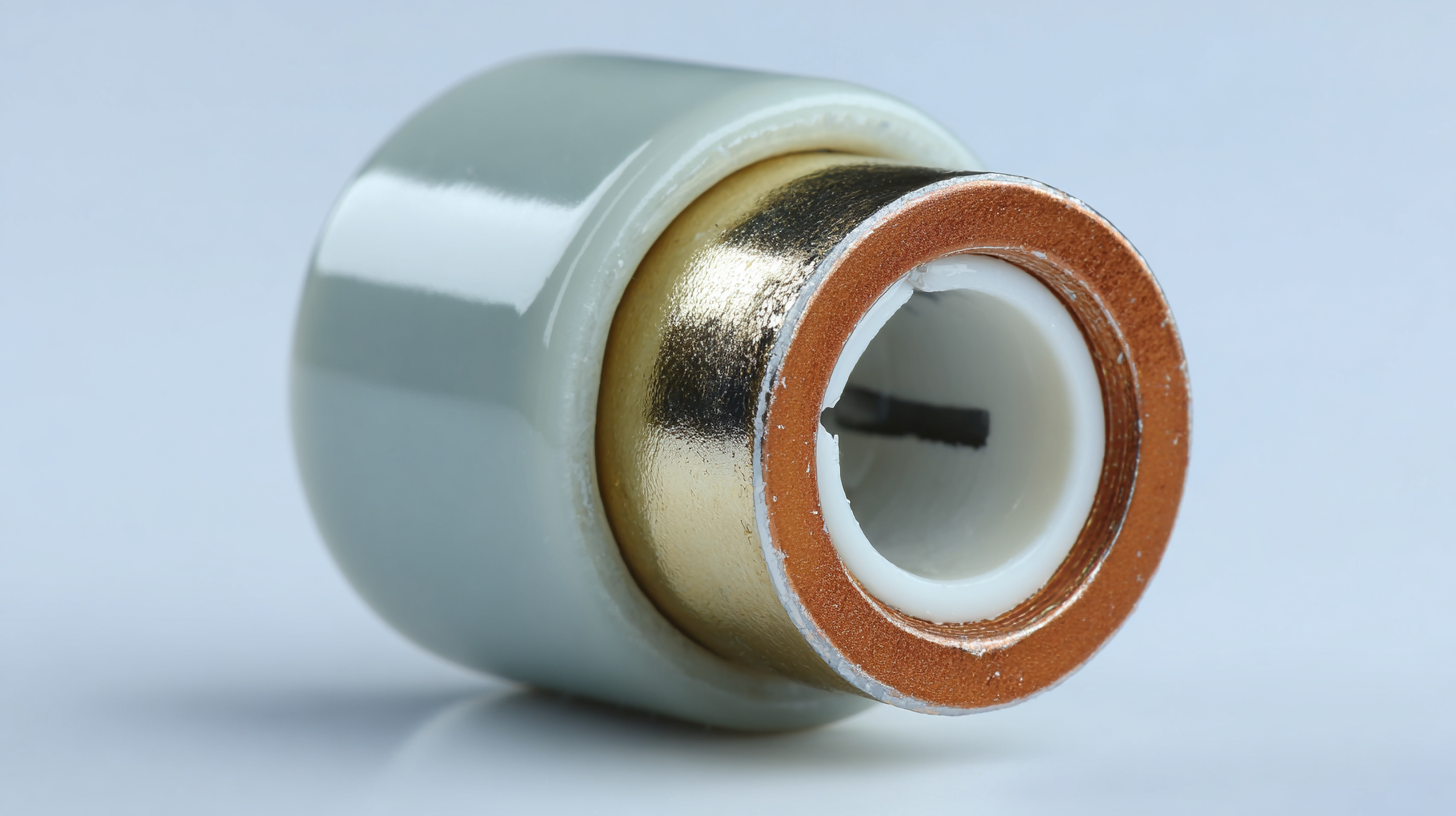

Ceramic fuses are essential components in electrical systems, providing protection against overloads and short circuits. Understanding the basics of ceramic fuses is crucial for selecting the right one for your applications. Ceramic fuses are made from a high-strength ceramic material that not only withstands high temperatures but also provides excellent performance in applications demanding high reliability. According to a report by MarketsandMarkets, the global fuse market is projected to grow at a CAGR of 5.8%, highlighting the increasing demand for reliable electrical safety components.

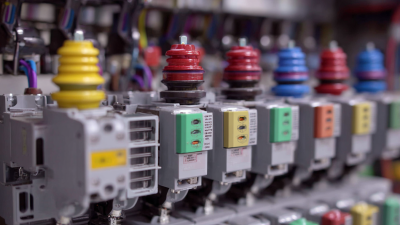

When choosing a ceramic fuse, consider the operating voltage and current limits specific to your application. The fuse rating must align with the maximum load your circuit will experience to ensure effective protection without nuisance blowing. Additionally, take into account the breaking capacity of the fuse, which indicates its ability to safely interrupt a fault current. Selecting a fuse with the appropriate breaking capacity can prevent catastrophic damage to your electrical system.

Incorporating the right strategies can streamline the selection process. For example, always verify the physical dimensions and mounting options of the fuse to ensure compatibility with your equipment. Additionally, consult manufacturer datasheets and industry standards to ensure compliance, which is critical for safety and efficiency. Following these tips can help you select a ceramic fuse that meets your specific electrical needs effectively.

When selecting a ceramic fuse for your electrical needs, several key factors should be considered to ensure optimal performance and safety. First and foremost, it is crucial to understand the electrical rating of the circuit you are dealing with. This includes the voltage and current requirements, as using a fuse with inappropriate ratings can lead to failure in protecting your electrical components or potentially create a fire hazard.

Another important factor is the physical size and mounting type of the fuse. Ceramic fuses come in various shapes and sizes, so compatibility with your existing equipment is essential. Additionally, consider the environment in which the fuse will operate. If the fuse is exposed to harsh conditions, such as high humidity or extreme temperatures, selecting a fuse specifically designed to withstand such conditions can enhance longevity and reliability.

Lastly, the fuse's response time is a significant consideration. Fast-acting fuses are ideal for circuits sensitive to overcurrent, while slow-blow fuses can tolerate temporary surges in current. By taking these factors into account, you can make a more informed choice, ensuring that the ceramic fuse not only protects your electrical systems effectively but also operates reliably over time.

When selecting a ceramic fuse for electrical applications, one of the critical factors to consider is the voltage rating. Ceramic fuses are designed to interrupt excessive currents, but if the voltage rating is not appropriately matched to the application, it can lead to fuse failure and, potentially, catastrophic equipment damage. According to a report by the Electrical Safety Authority, improper voltage selection is a leading cause of electrical faults, resulting in an estimated $2 billion in damages annually in the industry.

Voltage ratings in ceramic fuses indicate the maximum voltage that the fuse can safely interrupt without arcing or creating dangerous conditions. Standard voltage ratings range from 250V to 1000V, depending on the application. For example, the Institute of Electrical and Electronics Engineers (IEEE) suggests that for residential applications, using fuses rated for 250V is generally sufficient. However, for industrial applications, where power supply systems might operate at higher voltages, selecting fuses rated for 600V or more becomes essential. This careful consideration helps ensure that the fuse can safely handle the electrical demands of the circuit, optimizing reliability and safety in electrical systems.

Choosing the right amperage for your electrical system is crucial to ensure safety and efficiency. The amperage rating of a ceramic fuse needs to match the specific requirements of your application to prevent system overloads. According to the National Electrical Manufacturers Association (NEMA), over 60% of electrical faults can be attributed to improper fuse selection. It's essential to assess the total load on your circuits, factoring in all devices and appliances. For instance, if your circuit is designed for 20 amps, selecting a fuse rated significantly higher may allow excessive current that could lead to overheating and potential fire hazards.

In order to identify the appropriate amperage, consider the guidelines set by the Institute of Electrical and Electronics Engineers (IEEE), which recommends fuses to be rated at 125% of the continuous load. This is particularly important in residential settings where a standard 15 amp circuit may be used for multiple outlets. For example, if you anticipate a 12 amp draw, using a 15 amp fuse is advisable; however, a 20 amp fuse would be too high and could lead to unsafe conditions. Additionally, always consult the manufacturer's specifications for any equipment connected to the circuit, as these will include crucial information regarding maximum amperage and operational reliability.

| Tip Number | Tip Description | Recommended Amperage | Typical Application |

|---|---|---|---|

| 1 | Determine the total load of your circuit. | 10A | Lighting circuits |

| 2 | Consider inrush currents for motors. | 16A | Small motors |

| 3 | Use a fuse rating compatible with your wire gauge. | 20A | General purpose circuits |

| 4 | Ensure fuse type matches the expected fault conditions. | 25A | Heater circuits |

| 5 | Evaluate the environment where the fuse will be used. | 30A | Outdoor equipment |

| 6 | Match fuse ratings with circuit breaker settings. | 40A | Sub-panel circuits |

| 7 | Consider time-delay versus fast-acting fuses. | 50A | High-start applications |

| 8 | Check for fuse compatibility with existing fixtures. | 60A | Heavy-duty tools |

| 9 | Assess potential overloads in your system. | 70A | Industrial equipment |

| 10 | Consult electrical specifications for specific devices. | 80A | Commercial appliances |

When selecting ceramic fuses for electrical applications, avoiding common mistakes is crucial to ensure safety and functionality. One prevalent error is miscalculating the required amperage. According to a report by the National Fire Protection Association, improper fuse sizes lead to numerous electrical failures, often resulting in significant downtime and costly repairs. It is essential to consider the actual load and potential surges, as using a fuse rated too high can fail to provide adequate protection, while one rated too low may blow frequently, causing interruptions.

Another common mistake is overlooking the voltage ratings. A survey conducted by the Electric Power Research Institute found that around 30% of fuse failures occur due to voltage mismatches. Ensuring that the ceramic fuse matches or exceeds the circuit's voltage requirements is imperative to prevent catastrophic failures. Furthermore, buyers often neglect to assess the application environment. Fuses are designed with specific temperature and humidity ratings, and failing to consider these can lead to premature wear or unintended tripping. Understanding these critical aspects will significantly enhance the reliability and effectiveness of your electrical systems.

This chart illustrates the common ratings for ceramic fuses used in residential and industrial electrical systems. The data indicate the maximum current capacity (in Amperes) of each fuse type, helping you make informed decisions when selecting a fuse for your electrical needs.