-

Home

-

About Us

-

Products

-

News

-

Blog

-

Contact Us

Leave Your Message

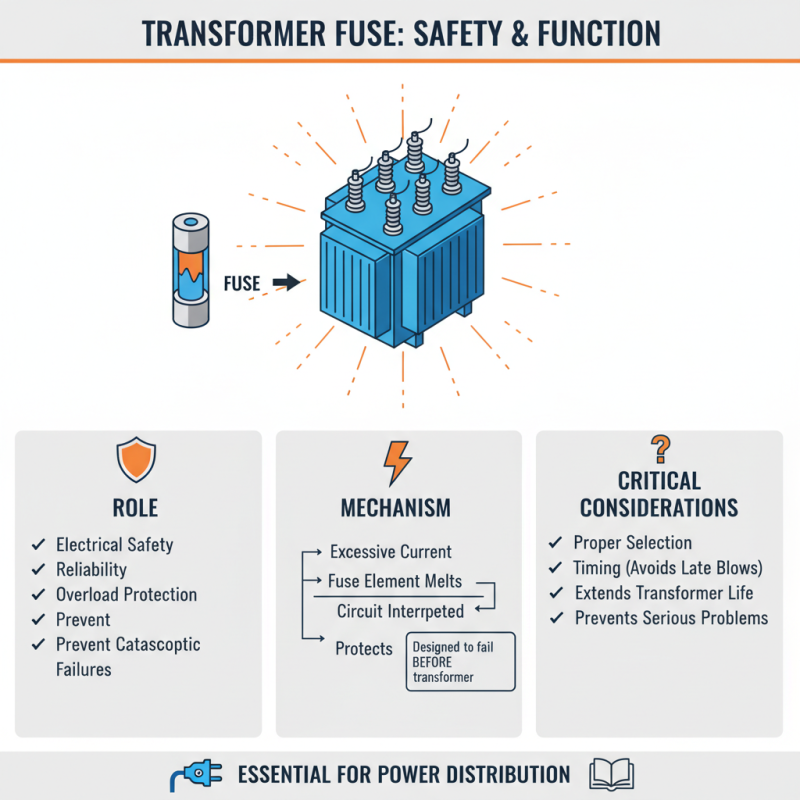

The "Fuse of Transformer" plays a crucial role in electrical safety and reliability. According to industry expert Dr. Emily Carter, "A fuse protects transformers from unexpected overloads." This simple device can prevent catastrophic failures. Understanding its function is essential for anyone working with transformers.

Fuses work by interrupting the circuit when excessive current flows. They are designed to fail before the transformer does. This failure is critical to preserving the integrity of the system. In many cases, fuses may not provide the protection anticipated. Some fuses blow too late, allowing damage to occur. Hence, selecting the right fuse is a nuanced decision that requires careful consideration.

Transformers are vital in power distribution. The efficiency of a transformer depends significantly on its protective components. A properly rated fuse can extend the life of the transformer. However, improper use or selection can lead to serious problems. Thus, the fuse of a transformer remains a subject worth deeper exploration and reflection. Understanding its intricacies can lead to safer practices in the industry.

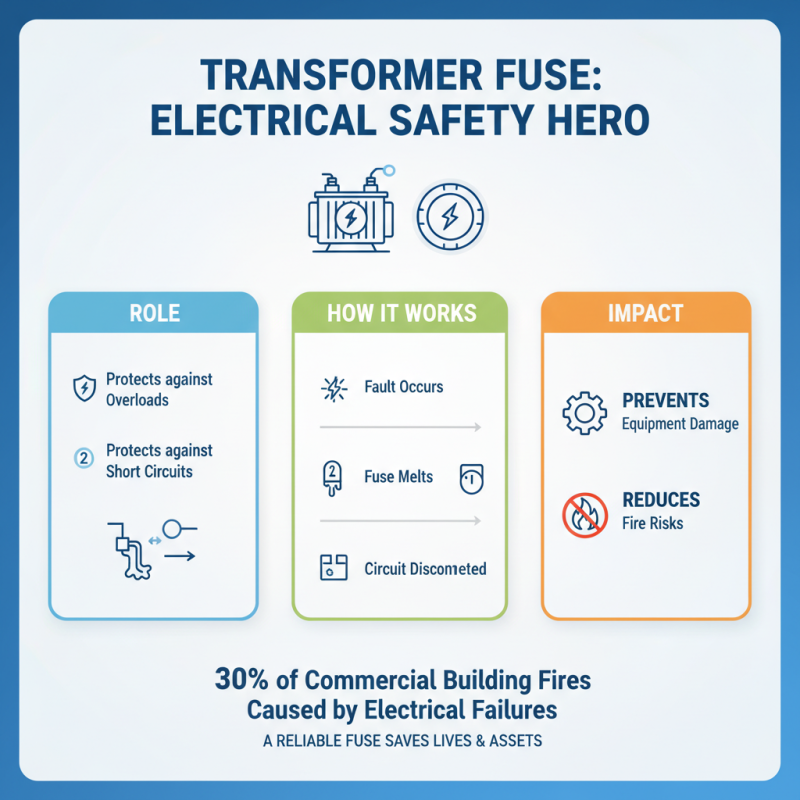

A transformer fuse plays a critical role in electrical safety. It offers protection against overloads and short circuits. When a fault occurs, the fuse melts and disconnects the circuit. This prevents equipment damage and reduces fire risks. According to a recent industry report, electrical failures cause 30% of fires in commercial buildings. A reliable fuse can significantly minimize these incidents.

The selection of a transformer fuse is vital. It must match the voltage and current rating of the transformer. Incorrect ratings can lead to fuse failure or unnecessary outages. An estimated 15% of fuses are improperly rated, highlighting the need for careful selection. Regular inspections are essential. Many facilities overlook this, putting their operations at risk.

Inadequate maintenance on fuses can result in significant downtime. Transformers account for about 25% of energy losses in electrical systems. Poor fuse management compounds this issue. Updating outdated technology can improve efficiency. Modern fuses, such as current-limiting fuses, provide better protection and response time. It's crucial to reflect on these aspects to enhance safety and efficiency in transformer operations.

In transformer systems, a fuse plays a crucial role in protecting equipment. It acts as a safety device that interrupts the electrical flow when excessive current occurs. This protects transformers from damage caused by overloads or short circuits. Fuses are typically simple, yet effective devices.

When the current exceeds a predetermined threshold, the fuse blows. This creates an open circuit, halting electricity flow. By doing so, it prevents potential failures of the transformer. Regular checks of fuses are essential to ensure they function properly. A blown fuse indicates a fault that needs immediate attention.

Tip: Always have spare fuses on hand. Replacing a blown fuse quickly can minimize downtime. Check the ratings on the fuses. Using the right type is vital for safety and functionality.

Be mindful that fuses can degrade over time. Regular inspection is necessary to identify wear and tear. Keeping a maintenance log helps track replacements and issues. Understanding how fuses work and their importance in transformer systems can lead to better maintenance practices.

| Fuse Type | Current Rating (A) | Voltage Rating (V) | Response Time (ms) | Application |

|---|---|---|---|---|

| Cartridge Fuse | 10-100 | 690 | 1-10 | Low Voltage Equipment |

| Blade Fuse | 1-40 | 32 | 10-20 | Automotive Applications |

| Ceramic Fuse | 1-100 | 500 | 5-15 | Industrial Equipment |

| MCB (Miniature Circuit Breaker) | 6-63 | 230 | 2-10 | Residential & Commercial |

| Resettable Fuse | 0.5-30 | 60 | <10 | Consumer Electronics |

Fuses play a critical role in protecting transformers from overloads and short circuits. There are several types of fuses used in these devices. Each type has its own unique characteristics, making them suitable for specific applications.

One common type is the expulsion fuse. It functions by utilizing an element that melts under excessive current, creating an arc. This arc is then expelled from the fuse, interrupting the circuit. The design is simple but effective, particularly in outdoor transformer installations where space is limited.

Another type is the current-limiting fuse. This fuse operates differently. It can detect high fault currents quickly and limit them before they can damage the transformer. These are often used in industrial settings where high power levels can lead to catastrophic failures. However, some users find them more complex to replace and maintain. The choice of fuse should consider the specific requirements and potential challenges of installation and operation.

Transformer fuses are essential for protecting electrical systems. They prevent damage caused by overcurrent situations. Regular maintenance of these fuses is vital. They should be checked periodically to ensure proper functionality. A common recommendation is to inspect fuses at least every six months. This proactive approach can enhance safety and reliability.

When it comes to replacing transformer fuses, safety must be the priority. Always disconnect power before beginning any work. Use appropriate personal protective equipment (PPE). In 2021, industry reports indicated that about 30% of electrical failures were due to improper fuse management. This alarming statistic highlights the need for diligence in fuse care.

Tips: Keep a maintenance log for each transformer. Document inspection dates and conditions of fuses. This will help track performance over time. Work with trained professionals when replacing fuses. Untrained personnel can inadvertently cause hazards. Remember, neglect can lead to costly downtime. Address any issues promptly and efficiently. Regular checks can prevent major failures, protecting your entire electrical system.

When dealing with transformer fuses, safety is paramount. These fuses protect transformers from overload and short circuits. A blown fuse can prevent costly damage and service interruptions. However, working with them requires a cautious approach. Always disconnect power before inspecting or replacing fuses. This is a critical step that many overlook.

Proper PPE is essential during this process. Insulated gloves and safety goggles offer protection against accidental shocks. It's crucial to verify the fuse type and rating before installation. Mismatched fuses can lead to system failures. Inspect the fuse box for any signs of wear or heat damage. Avoid working in wet conditions, as this can increase the risk of electric shock.

Regular maintenance checks can help in catching potential issues early. Document any changes made to the fuse system. Miscommunication can lead to dangerous situations in shared work environments. Understanding the specifics of transformer fuses can reduce the likelihood of accidents. Continuous education on safety protocols is important for everyone involved. Neglecting these aspects can lead to serious, sometimes irreversible consequences.