-

Home

-

About Us

-

Products

-

News

-

Blog

-

Contact Us

Leave Your Message

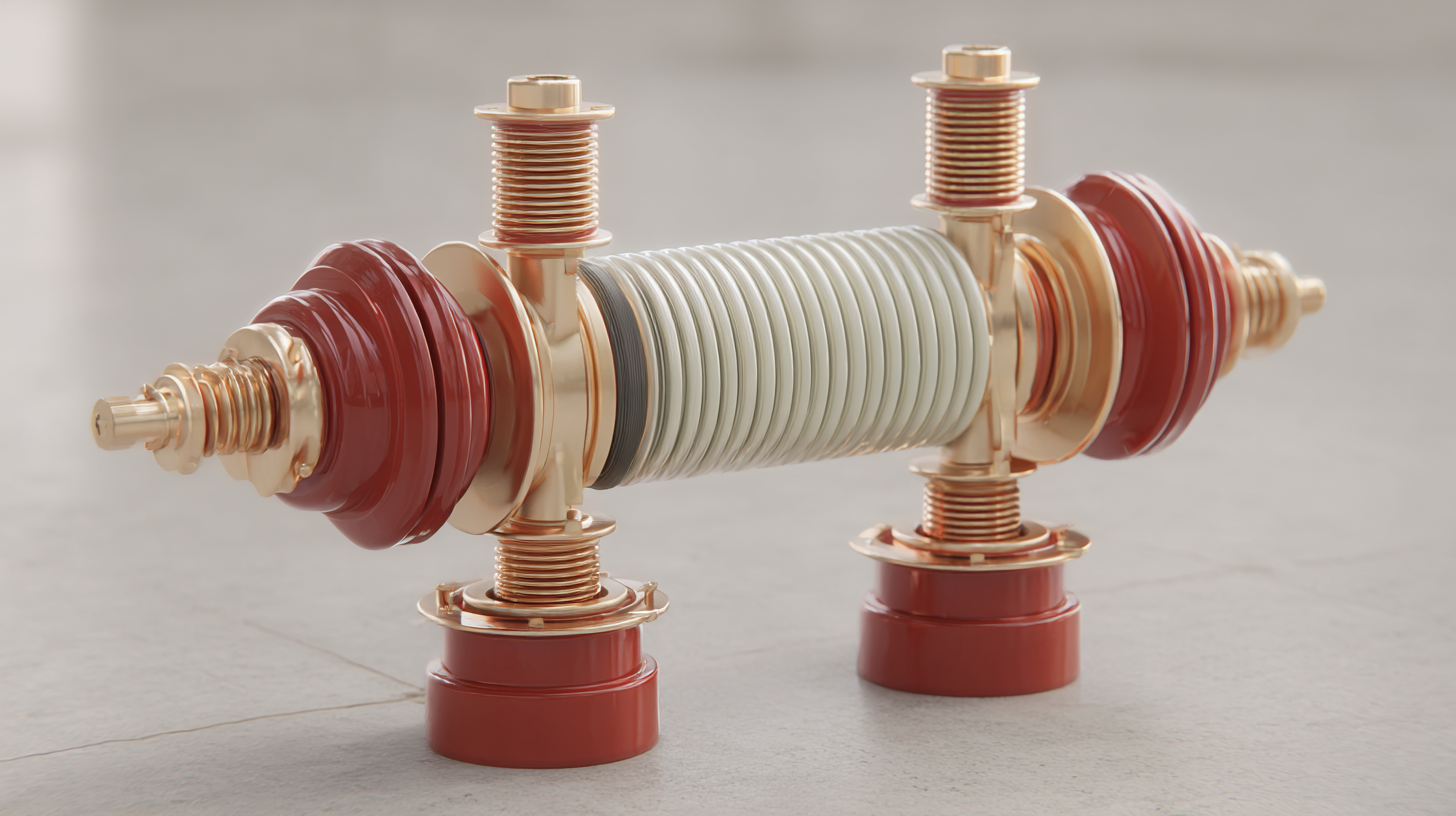

The future of electrical insulation technology is rapidly evolving, with Composite Polymer Insulators (CPI) leading the charge in advancements. As per a recent industry report by Markets and Markets, the global composite insulator market is projected to reach USD 3.82 billion by 2025, expanding at a CAGR of 7.8% from 2020. This growth is largely driven by the increasing demand for lightweight, high-performance materials in power transmission and distribution systems, as CPI can withstand harsh environmental conditions better than traditional ceramic insulators.

Additionally, the benefits of reduced maintenance costs and enhanced electrical performance make Composite Polymer Insulators an attractive option for utility companies striving for efficiency and reliability. As we delve into the top strategies for embracing this innovative technology, it becomes clear that adaptation and integration of CPI are vital for the future of sustainable energy infrastructure.

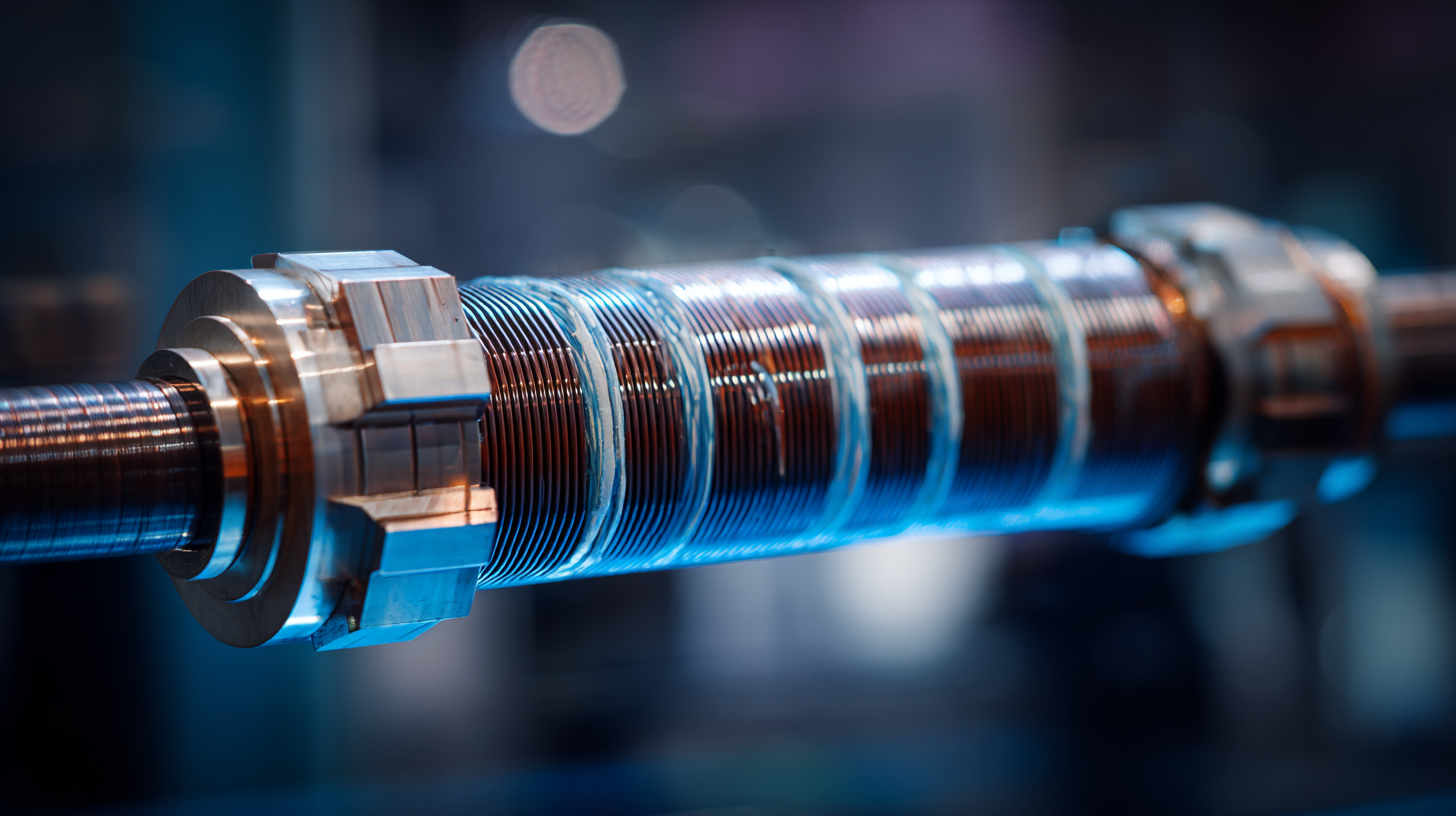

In recent years, the power industry has witnessed a transformative shift towards advanced composite polymer insulators. These innovative materials are revolutionizing modern power systems by offering significant advantages over traditional ceramic and glass insulators. With the growing demand for reliable and efficient energy transmission, the adoption of advanced composite polymer insulators is on the rise, promising improved performance in various environmental conditions.

In recent years, the power industry has witnessed a transformative shift towards advanced composite polymer insulators. These innovative materials are revolutionizing modern power systems by offering significant advantages over traditional ceramic and glass insulators. With the growing demand for reliable and efficient energy transmission, the adoption of advanced composite polymer insulators is on the rise, promising improved performance in various environmental conditions.

Advanced composite polymer insulators are designed to withstand extreme weather, resist corrosion, and reduce maintenance costs significantly. Their lightweight nature allows for easier installation and transportation, which is particularly beneficial in remote or challenging locations. Additionally, these insulators exhibit excellent electrical properties, enhancing the overall reliability of power systems. As utilities strive to meet increasing energy demands while addressing environmental concerns, the shift towards advanced composite polymer insulators marks a pivotal step toward sustainable and resilient infrastructure.

The future of power delivery is not only brighter but also more efficient, thanks to these state-of-the-art materials.

The integration of digital technologies into the production and monitoring of advanced composite polymer insulators is revolutionizing the electrical utility sector. Recent reports indicate that digital transformation can enhance operational efficiency by up to 30%, significantly reducing maintenance costs. This shift not only improves the performance and reliability of insulators but also ensures a longer lifespan, with some studies suggesting a lifespan increase of over 50% when employing smart monitoring systems.

By leveraging data analytics and IoT (Internet of Things) technologies, utilities can predict failures before they happen. For instance, sensors embedded within insulators can capture real-time data on environmental conditions and mechanical stress, allowing for proactive maintenance strategies. According to a report by the International Energy Agency, digital integration is expected to yield an additional savings potential of $30 billion by 2030 in the global electrical infrastructure.

Tips: To maximize the benefits of digital integration, utilities should invest in training for staff to effectively interpret data and respond to insights. Additionally, leveraging cloud-based platforms can facilitate easier data management and collaboration across teams, fostering a culture of innovation and responsiveness in maintaining insulator systems.

The advancements in composite materials are paving the way for innovative applications across industries, particularly with the rise of advanced composite polymer insulators. Recent market studies highlight significant growth in sectors leveraging these materials. For instance, the automotive industry is projected to grow from $99.27 million in 2023 to $104.74 million in 2024, with a forecasted increase to $146.75 million by 2032, showcasing a robust compound annual growth rate (CAGR). This growth illustrates the rising demand for durable and lightweight materials in electric vehicles.

Tips: When choosing composite materials for your projects, consider their weight-to-strength ratios and resilience against environmental factors. These properties can substantially enhance the performance and durability of your products.

In the realm of energy storage and aerospace, innovations in silicon-based anodes have led to revolutionary changes, mainly due to their promising application in consumer electronics and electric vehicles. Expected trends suggest a continued investment in these technologies as they are crucial for improving energy efficiencies and pushing the boundaries of material capabilities.

Tips: Look for composites that offer not just weight savings but also energy efficiency, as these attributes are essential for future-proofing your applications in competitive markets.

The performance of advanced composite polymer insulators in harsh environments is a critical area of exploration for the electrical utility industry. Recent studies indicate that these insulators can withstand extreme temperatures ranging from -40°C to 100°C, ensuring reliable operation in diverse climatic conditions. A report from the Electric Power Research Institute (EPRI) highlights that polymer insulators demonstrate superior hydrophobicity, reducing the risk of contamination and flashover by up to 30% compared to traditional ceramic insulators. This enhanced performance is essential for maintaining grid integrity and reducing maintenance costs.

Moreover, the long-term mechanical robustness of advanced composite polymer insulators under varying loads contributes to their growing adoption. According to the International Council on Large Electrical Systems (CIGRÉ), these insulators can endure mechanical loads exceeding 100 kN, making them ideal for high-stress installations, especially in coastal or industrial regions where environmental factors can contribute to rapid deterioration. The durability coupled with low weight also allows for easier installation and less strain on supporting structures, leading to a more efficient deployment in challenging terrains. As the demand for reliable electrical infrastructure increases, achieving optimal performance metrics in such insulators becomes paramount for future developments.

The integration of AI and IoT technologies is transforming the way we monitor and maintain advanced composite polymer insulators. With the growing demand for reliable power infrastructure, the continuous thermal monitoring market is expected to witness significant growth, driven by the need for enhanced predictive maintenance strategies. According to recent research, the continuous monitoring of electrical transformers leads to a reduced downtime of up to 30% and optimizes power grid efficiency, ultimately supporting large-scale infrastructure projects that are proliferating across the MENA region.

Moreover, the application of AI in the management of hydrogen fuel cells showcases the potential for smart monitoring systems to revolutionize energy management. By employing AI algorithms, stakeholders can improve operational efficiency and predictive capabilities, resulting in a performance enhancement of up to 25%. The IoT's ability to collect real-time data from various components empowers operators to make informed decisions regarding maintenance and operation, which is critical as the infrastructure landscape continues to evolve amidst urban development. This synergy between AI and IoT not only enhances performance but also ensures the longevity of advanced polymer insulators, paving the way for a sustainable energy future.

This bar chart illustrates the effectiveness of AI and IoT technologies in enhancing the monitoring and maintenance of advanced composite polymer insulators over the past five years. The data shows the percentage improvement in efficiency, reduced maintenance costs, and increased lifespan of insulators.