-

Home

-

About Us

-

Products

-

News

-

Blog

-

Contact Us

Leave Your Message

In critical power systems, ensuring reliability is paramount, particularly in industries such as utilities, healthcare, and data centers where downtime can lead to significant financial losses and operational disruptions. According to a report by the Electric Power Research Institute (EPRI), equipment failures due to overcurrents account for a substantial percentage of outages, highlighting the need for effective protective devices. High Voltage Fuses play a crucial role in safeguarding electrical systems by providing reliable overcurrent protection and minimizing the risk of catastrophic failures. As per the latest market analysis by MarketsandMarkets, the global high voltage fuse market is projected to grow at a CAGR of 7.2% from 2022 to 2027, reflecting increasing investments in power infrastructure and the rising emphasis on system reliability. This underscores the importance of selecting the right type of high voltage fuses to enhance system integrity in critical applications, ensuring uninterrupted and stable power delivery.

High voltage fuses play a critical role in ensuring the reliability of power systems by providing essential protection against overcurrents. According to a report by the International Electrotechnical Commission (IEC), failures in electrical systems can lead to economic losses of approximately $150 billion annually worldwide. This data highlights the importance of maintaining the integrity of power systems, particularly in critical applications such as hospitals, data centers, and industrial processes, where downtime can have severe repercussions.

The use of high voltage fuses can significantly improve system reliability. A study by the Edison Electric Institute (EEI) indicates that the implementation of modern fuse technologies can reduce equipment failures by up to 30%. These fuses are designed to clear faults quickly and efficiently, thus minimizing the duration of outages and maintaining the continuity of service. By ensuring that high voltage fuses are correctly selected and installed, power system operators can enhance operational efficiency and reduce the risk of catastrophic failures.

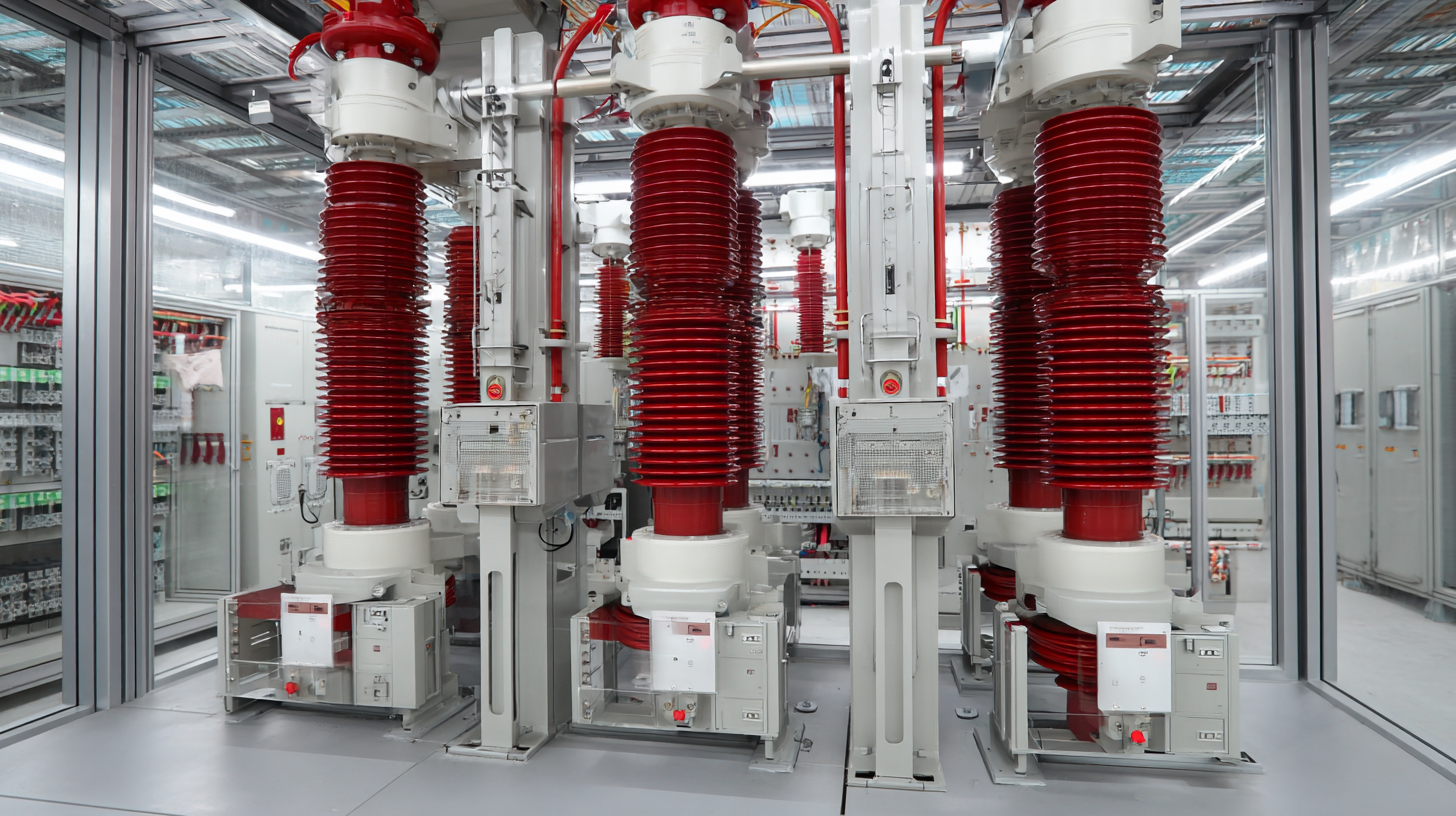

High voltage fuses play a critical role in ensuring the reliability of power systems across various industries. They are essential in protecting electrical equipment by preventing excessive currents that can lead to catastrophic failures. In sectors such as manufacturing, energy, and telecommunications, the use of high voltage fuses is increasingly common due to the rising demand for uninterrupted power supply and equipment longevity. These fuses are designed to act quickly in the event of an overload, thereby safeguarding vital components and minimizing downtime.

When selecting high voltage fuses for your applications, consider the following tips: First, ensure that the fuse ratings match the operational requirements of your system. Proper sizing is crucial to prevent nuisance tripping while still providing adequate protection. Second, assess the environmental conditions. Fuses are available in various designs suitable for harsh environments, including moisture, dust, and extreme temperatures. Lastly, collaborate with manufacturers who offer comprehensive support, from installation guidelines to ongoing maintenance to ensure optimal performance.

In terms of industries, high voltage fuses have proven indispensable in power generation plants, where they protect transformers and distribution equipment. In renewable energy sectors, such as solar and wind, fuses help maintain system integrity against faults. By investing in high voltage fuses tailored for specific applications, industries can enhance their operational reliability and efficiency, addressing the critical need for stability in modern electrified landscapes.

High voltage fuses play a critical role in ensuring the reliability of power systems, particularly in applications where failure can result in catastrophic consequences. The mechanisms behind high voltage fuse operation are complex yet fundamental to their effectiveness in circuit protection. High voltage fuses work by interrupting current flow when an overcurrent condition is detected, utilizing thermal, electromechanical, and plasma mechanisms to achieve fast and reliable operation. The latest advancements in fuse technology, such as the innovative two-stage forming fuses, are designed to enhance protection against high power pulses, making them indispensable components in modern electrical systems.

Recent studies indicate that the failure of protective devices like high voltage fuses can lead to severe operational risks in critical infrastructures. A comprehensive review highlighted the importance of incorporating robust detection and early warning systems to mitigate risks associated with phenomena like DC arc faults in battery systems. This is especially relevant given the increasing deployment of high-performance batteries, which demands advanced circuit protection solutions. Effective fuse operation not only protects equipment but also helps in maintaining the overall integrity and efficiency of power transmission mechanisms, ultimately contributing to safer electricity distribution in a rapidly evolving energy landscape.

The rapid evolution of power systems has spurred significant innovations in fuse technologies, particularly in the realm of high voltage fuses. With the increasing demand for reliable and efficient power distribution, manufacturers are focusing on developing advanced fuse designs that enhance performance and ensure system integrity. Technologies such as smart fuses, which incorporate digital monitoring capabilities, are becoming more prevalent. These devices provide real-time data on system conditions, enabling quick responses to potential faults, thus minimizing downtime and protecting essential electrical components.

Moreover, recent industry trends highlight a shift towards eco-friendly materials and sustainable manufacturing processes in fuse production. The integration of advanced materials not only improves the durability and longevity of fuses but also reduces environmental impact. Additionally, the incorporation of automated production techniques ensures high precision and consistency, meeting the growing expectations for quality in critical power systems. As these innovations continue to reshape the landscape of fuse technology, they play a crucial role in enhancing the reliability of power systems that millions depend on daily.

| Feature | Description | Recent Trends | Innovations |

|---|---|---|---|

| Response Time | High voltage fuses react rapidly to overcurrent conditions to minimize damage. | Focus on faster acting fuses to enhance system durability. | Introduction of materials with enhanced thermal conductivity. |

| Material Innovation | Use of advanced ceramics and composites for better performance. | Shift towards sustainable and recyclable materials. | Development of biodegradable fuses for environmental safety. |

| Smart Technology | Integration of sensors for real-time monitoring of fuse health. | Rise in IoT-enabled components within power systems. | Fusion of AI algorithms for predictive maintenance. |

| Safety Standards | Compliance with international safety regulations for electrical components. | Increasing regulatory scrutiny on materials and manufacturing processes. | Enhancements in testing procedures for reliability assurance. |

When it comes to critical power systems, the selection and implementation of high voltage fuses are paramount for ensuring reliability. According to the IEEE Standard 34, approximately 30% of power outages are attributed to equipment failures, where the role of high voltage fuses becomes crucial. Best practices involve understanding the fuse ratings, environmental considerations, and the characteristics of the electrical load. Selecting fuses that align with the specific application requirements, such as voltage rating and interrupting capacity, mitigates risks and enhances operational reliability.

Additionally, the installation of high voltage fuses should consider geographical and operational factors, including temperature fluctuations and humidity levels. A report by the Electric Power Research Institute (EPRI) indicates that improper selection of fuses can lead to increased maintenance costs by up to 25%. Implementing rigorous testing protocols and regular maintenance schedules can further ensure that these protective devices operate optimally. Utilizing real-time monitoring technology to track fuse performance can also provide insights into potential issues before they result in system failures, demonstrating that thorough planning and execution in the selection and implementation phases significantly enhance the resilience of power systems.