-

Home

-

About Us

-

Products

-

News

-

Blog

-

Contact Us

Leave Your Message

Ensuring safety when working with High Voltage Xrnt is crucial. This equipment can be dangerous if not handled properly. Understanding its features and risks is vital for everyone involved.

High Voltage Xrnt requires specific maintenance practices to function effectively. Regular inspections are crucial. Ignoring minor issues can lead to bigger problems. Proper training is essential for operators. They must know what to look for during maintenance.

In addition, safety gear is not optional. Wearing suitable protective clothing can prevent serious injuries. However, some users might overlook this aspect. Choices can be personal, but safety should always come first. Ultimately, safe use of High Voltage Xrnt stems from knowledge and attention. This is an area where reflection can lead to improvement.

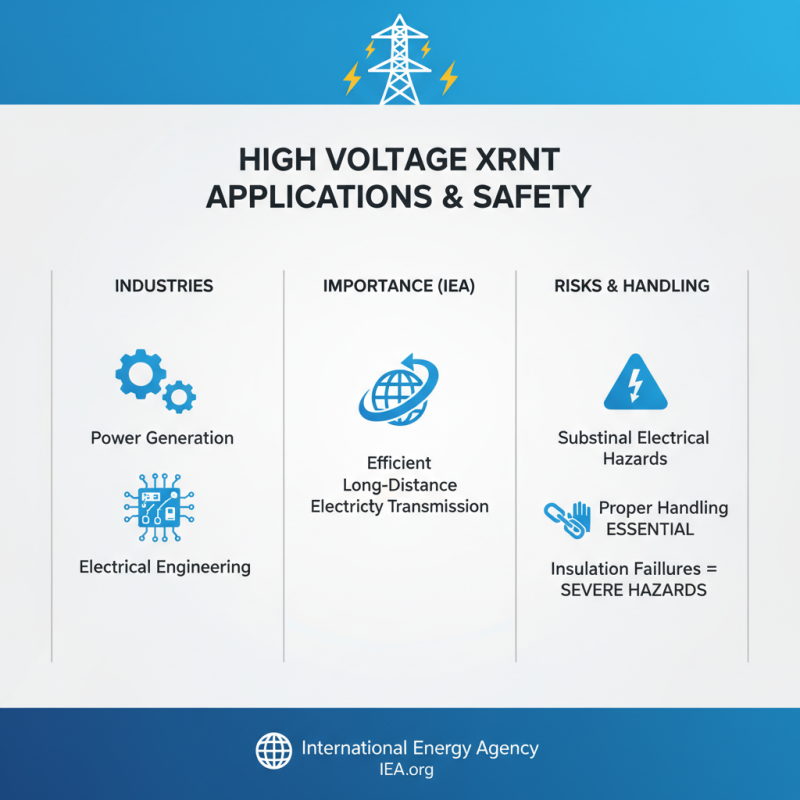

High voltage Xrnt applications span various industries, including power generation and electrical engineering. According to the International Energy Agency, high voltage systems are crucial for efficient electricity transmission over long distances. However, these systems come with substantial risks. Proper handling is essential. Insulation failures can lead to severe electrical hazards.

Operators must undergo extensive training to mitigate these dangers. A study published in the Journal of Safety Research reported that over 40% of high voltage accidents stem from human error. Regular maintenance is just as vital. Equipment should be inspected regularly for wear and tear. Neglecting these checks might result in costly failures.

Awareness of potential electrical hazards is key. Industry guidelines recommend using protective gear when working with high voltage Xrnt systems. Furthermore, using clear signage around high voltage areas is critical. This simple step reduces the risk of accidental contact. With continual education and strict adherence to safety protocols, the risks associated with high voltage Xrnt can be greatly minimized.

Working with high voltage Xrnt requires strict adherence to safety precautions. The risks are significant; statistics show that contact with high voltage can lead to severe injuries or fatalities. Proper training and awareness are essential for anyone in this field. Ensure all workers understand the potential hazards before approaching any high voltage equipment.

Tip 1: Always wear appropriate personal protective equipment (PPE). Insulated gloves and rubber-soled shoes are not optional. A lack of proper attire can be disastrous. Regular equipment inspections can prevent electrical failures.

It's crucial to maintain a clear work environment. Clutter can lead to accidents and distractions. Ensure all tools and materials are stored safely. Provide adequate signage to warn others of high voltage areas.

Tip 2: Implement a lockout/tagout (LOTO) system. This practice greatly reduces the risk of accidental energization. Workers must follow established protocols to ensure all sources of energy are properly controlled before maintenance. Remember, not following these methods could lead to grave consequences.

High voltage work demands respect and caution. Reflecting on past incidents can provide valuable lessons. Learning from mistakes is key to improving safety practices.

High voltage equipment like Xrnt requires meticulous attention. Proper maintenance ensures safety and longevity. According to industry reports, equipment failures can lead to significant downtime and costly repairs. Consistent inspections are vital. Check for signs of wear and tear regularly.

Tips for maintenance include maintaining clear ventilation. Dust and debris can accumulate. This hinders performance and can lead to overheating. Keep the work area tidy. Every small detail matters. Implement a routine for checking connections and safety switches. Data suggests that neglecting these checks can increase the chance of malfunctions, leading to hazards.

Another key aspect is keeping records of maintenance. Document every inspection and repair. This practice aids in identifying patterns in equipment failures. It also assists in making informed decisions about upgrades or replacements. Ignoring this can result in repeated issues, wasting both time and resources. Always prioritize safety and efficiency when dealing with high voltage Xrnt equipment.

| Dimension | Guideline | Frequency |

|---|---|---|

| Insulation Resistance | Check insulation resistance using a megohmmeter. | Monthly |

| Visual Inspection | Inspect for visible damage or wear on cables and equipment. | Weekly |

| Grounding System | Verify grounding connections and system integrity. | Quarterly |

| Circuit Load Monitoring | Monitor circuit loads to ensure they are within safe limits. | Daily |

| Thermal Imaging | Conduct thermal imaging scans to identify hotspots. | Bi-annually |

| Equipment Training | Ensure operators are trained on high voltage safety protocols. | Annually |

High voltage XRNT equipment can face various issues over time. Common problems include overheating, inconsistent output, and sudden shutdowns. Such issues may arise from poor maintenance or improper usage practices. It is essential to monitor the equipment regularly. Check for signs of wear and loose connections. Ignoring minor problems can lead to bigger failures.

When troubleshooting, start with the basics. Ensure all connections are secure and that the equipment is placed in a well-ventilated area. Excessive dust can block ventilation. Clean the components regularly but handle them with care. For unexpected shutdowns, check power sources and circuit settings. Sometimes a simple reset can solve the problem, but don’t rely on quick fixes. Reflect on how maintenance habits can be improved for longer lifespan.

Users should also educate themselves about safety protocols. High voltage work carries risks. Understanding the common failure points can greatly minimize hazards. If issues persist, consider seeking professional help. It's okay to ask for assistance. A proactive approach to troubleshooting ensures the equipment performs well and safely.

Working with high voltage equipment demands caution and knowledge. Safety should always be the top priority. Wear protective gear, such as insulating gloves and safety goggles. This reduces the risk of injury during operations. Always inspect your equipment before use. Look for damaged wires or faulty connections. It’s crucial to maintain your tools and devices, as wear and tear can lead to serious failures.

When operating high voltage systems, keep your workspace tidy. Clutter can cause distractions, increasing the chance of mistakes. Ensure you have clear access to emergency shut-off systems. If something goes wrong, knowing how to respond quickly can save lives. Use barriers or warning signs to alert others to the potential danger.

Regular training sessions can help keep your skills sharp. Even experienced operators can forget crucial safety measures over time. Reflect on your actions after each use. What went well? What could improve next time? This habit fosters a culture of safety and vigilance that benefits everyone. Ensure all team members understand the risks involved. Communication is key to maintaining a safe environment during high voltage operations.