-

Home

-

About Us

-

Products

-

News

-

Blog

-

Contact Us

Leave Your Message

Electrical safety is paramount in our increasingly electrified world. High Voltage Xrnt plays a crucial role in this landscape. Dr. Emily Roberts, a renowned expert in electrical safety, states, "Understanding High Voltage Xrnt is key to preventing accidents." Her words highlight the importance of this technology in safeguarding lives.

High Voltage Xrnt is not just a term; it represents a commitment to safety. Each year, electrical incidents occur due to a lack of awareness about high voltage risks. Implementing High Voltage Xrnt standards can significantly reduce these incidents. Imagine a worker confidently operating near high voltage lines, equipped with the proper knowledge and tools. This scenario illustrates the tangible benefits of focusing on High Voltage Xrnt practices.

Yet, is the industry doing enough? Many organizations still overlook critical training programs on High Voltage Xrnt. This gap can lead to serious accidents. Companies must reflect on their safety protocols and prioritize education in high voltage environments. Making High Voltage Xrnt a routine part of training can empower workers and enhance safety overall.

High Voltage XRNT, or High Voltage Electrical Risk Network Technology, plays a crucial role in electrical risk management. It addresses serious hazards in electrical systems. According to a report by the National Fire Protection Association, electrical failures are a leading cause of workplace fires. Integrating XRNT can significantly reduce these risks.

Employing High Voltage XRNT allows for real-time monitoring of electrical systems. This technology helps identify issues before they escalate. A study shows that predictive maintenance can reduce unforeseen outages by up to 40%. However, not all systems are equipped with this technology. Many facilities still rely on outdated methods that can lead to catastrophic failures.

Understanding electrical risks isn’t just about technology; it includes training staff. A lack of training can undermine even the best systems. Statistics indicate that human error is responsible for over 70% of electrical accidents. Investments in training alongside XRNT implementation are vital for comprehensive safety. Organizations must strive for a balanced approach to enhance overall electrical safety and risk management.

| Parameters | Description | Importance in Electrical Safety |

|---|---|---|

| Voltage Level | Typically above 1000 volts | High voltage can lead to severe electrical shocks, requiring robust safety measures. |

| XRNT Definition | Electrical risk management technique to assess and minimize hazards. | Critical for identifying potential safety hazards in high voltage systems. |

| Risk Assessment | Process of evaluating the safety measures in place. | Ensures that electrical systems comply with safety standards and regulations. |

| Protective Gear | Specialized clothing and equipment designed for high voltage work. | Important for personal safety and injury prevention while working with high voltages. |

| Training and Certification | Programs designed to educate workers on safe practices. | Essential for ensuring that personnel are knowledgeable about risks and safety measures. |

Understanding electrical safety standards is crucial when discussing High Voltage XRNT. High Voltage systems can exceed 1000 volts. These systems pose significant risks if not handled properly. According to a report by the IEEE, improper maintenance of high voltage equipment accounts for approximately 30% of electrical accidents.

XRNT refers to Cross-Linked Polyethylene insulation technology. This technology helps minimize electrical leakage. It also enhances cable durability. But not all installations consider these safety standards. Many older systems still use outdated materials, increasing potential hazards. Inadequate training for technicians contributes to these issues.

A survey found that 45% of electrical workers reported insufficient training in high voltage safety protocols.

Regulatory agencies emphasize the importance of compliance. The National Fire Protection Association (NFPA) highlights that adherence to safety standards reduces incidents by 25%. However, many facilities neglect regular audits. This oversight can lead to devastating consequences. High Voltage XRNT is vital for protection, but system integrity must be prioritized to ensure safety.

High voltage XRNT (External Rated Neutral Transformer) plays a crucial role in electrical systems. Ignoring its importance can lead to severe consequences. According to a report by the National Fire Protection Association, electrical failures cause over 50,000 home fires annually. Incidents often stem from neglecting high voltage safety standards. This oversight can result in significant property damage and even loss of life.

Electrical systems are complex and hazardous. Without proper safeguards, the risk of electric shock and arc flash incidents increases. The Occupational Safety and Health Administration (OSHA) reports that electrical hazards are one of the top four causes of workplace fatalities. Investing in high voltage XRNT can help mitigate these risks.

Tips: Regularly inspect electrical systems. Ensure that all components, including XRNT, are rated for the appropriate voltage. This simple check can prevent catastrophic failures. Additionally, training staff on high voltage risks and safety procedures is essential. Ensuring everyone understands the dangers can save lives. It’s also crucial to update older systems. Aging equipment often lacks necessary safety features, leading to increased risks.

High Voltage XRNT is crucial for maintaining electrical safety. Ignoring it can lead to severe consequences such as electrical fires, equipment damage, personal injury, operational downtime, and potential legal issues, each with a varying degree of severity.

High voltage electrical systems pose significant risks. Recent studies indicate that nearly 1,500 electrical accidents occur every year in industrial settings. These incidents often lead to serious injuries or fatalities. Enhanced safety measures are needed for workers handling high voltage equipment.

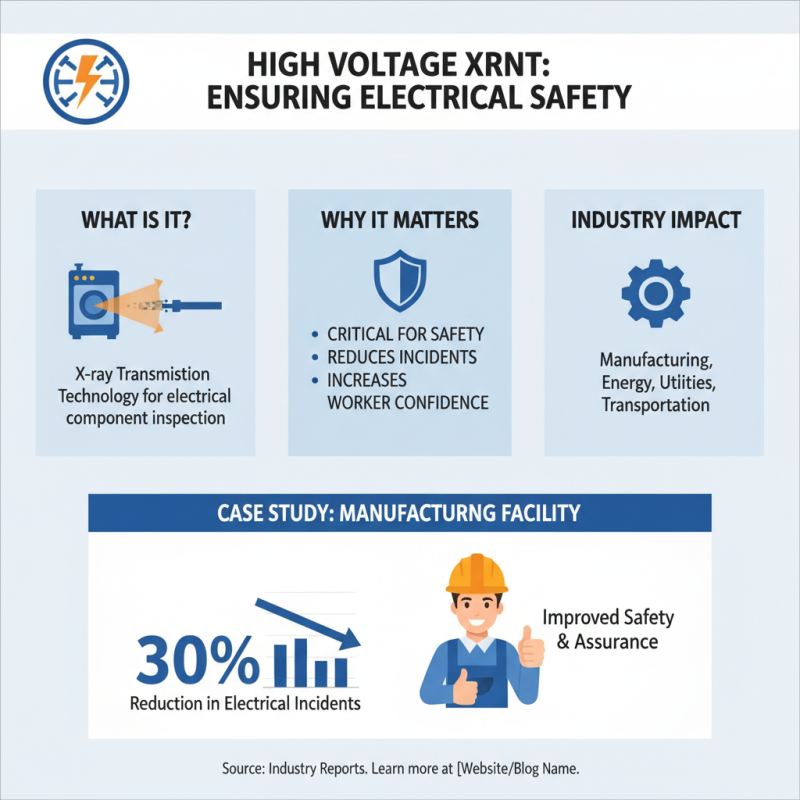

Technological advancements in high voltage X-rays and non-destructive testing (XRNT) play a crucial role in improving safety standards. New XRNT tools can detect potential failures before they escalate. For instance, a recent report showed that using XRNT can reduce equipment failure rates by up to 30%. This technology helps to identify faults hidden from view. It is particularly effective in examining insulated cables and connectors.

Despite advancements, some challenges remain. Many industries still rely on outdated inspection methods. This increases the risk of accidents. Training on new technologies is also lacking in some areas. Proper education can amplify the benefits of XRNT. Investing in technology alone isn’t enough; comprehensive training is required to ensure safety. Therefore, there is a pressing need for ongoing training programs that focus on the latest technological innovations in electrical safety.

High voltage XRNT (X-ray transmission) has become vital in ensuring electrical safety. Many industries rely on it for effective safety measures. Several case studies highlight this importance, showing positive outcomes from the implementation of XRNT. For instance, a manufacturing facility integrated XRNT in their safety protocols. They reported a 30% reduction in electrical incidents. Workers felt more secure, knowing that safety checks were thorough.

Another example comes from the energy sector. A utility company adopted XRNT technology to assess their high voltage equipment. The results revealed hidden issues that traditional methods missed. This proactive approach prevented potential failures and accidents. However, implementing XRNT is not without challenges. Some staff struggled with the new system, requiring additional training. This adjustment period raised questions about the best way to foster understanding and competence among employees.

Reflecting on these cases, it is clear that XRNT plays a significant role in improving safety standards. Yet, the human factor remains crucial in its effectiveness. Continuous training and adaptation are needed. Organizations must balance technology with employee engagement to maximize safety.