-

Home

-

About Us

-

Products

-

News

-

Blog

-

Contact Us

Leave Your Message

In today's rapidly evolving energy landscape, the importance of reliable and efficient power distribution cannot be overstated. At the heart of this system are components like Cooper Power Fuses, which serve as critical safeguards against electrical failures and overloads. Understanding how to effectively utilize these fuses is essential for electrical engineers, technicians, and anyone involved in power management. This comprehensive tutorial aims to provide a detailed checklist for mastering Cooper Power Fuses, ensuring that you can optimize their performance and longevity in various applications. By following the guidelines outlined in this tutorial, users will be better equipped to make informed decisions, utilize best practices, and ultimately enhance the reliability of their power systems. Whether you're a seasoned professional or just starting out, this tutorial is designed to empower you with the knowledge needed to excel in the efficient usage of Cooper Power Fuses.

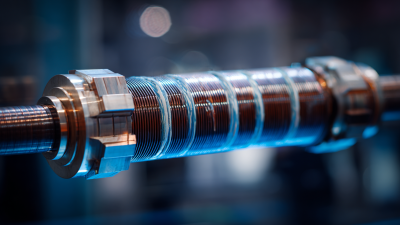

Cooper Power Fuses play a crucial role in ensuring the reliability and safety of electrical systems. Understanding their functionality is essential for effective application in various industries. These fuses are designed to protect electrical circuits by interrupting the current flow during overloads or short circuits, thus preventing damage to electrical equipment. According to industry reports, the global market for power fuses is expected to grow significantly, driven by the increasing demand for efficient power management systems. This growth reflects the vital need for reliable protection in today’s complex electrical grids.

In practical applications, Cooper Power Fuses are utilized in substations, distribution networks, and renewable energy installations. Their ability to respond quickly to fault conditions enhances system resilience and minimizes downtime. For instance, advancements in technology have led to the development of smart fuses that integrate monitoring capabilities, allowing utilities to assess the health of their electrical infrastructure in real time. A recent study highlights that integrating such technologies can improve operational efficiency by up to 30%, showcasing the necessity for utilities to adopt innovative solutions like Cooper Power Fuses to meet the ever-evolving demands of the energy sector.

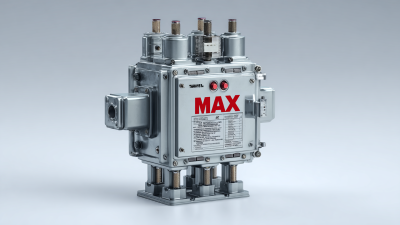

When it comes to ensuring the reliability and efficiency of electrical systems, selecting the right type of Cooper Power Fuse is crucial. Cooper Power Fuses are categorized into various types, including distribution fuses, substation fuses, and specialty fuses, each tailored to meet specific operational requirements. According to a recent industry report from the Electrical Apparatus Service Association (EASA), choosing the appropriate fuse can enhance system protection and significantly reduce downtime by up to 30% in critical applications.

Distribution fuses, for example, are designed to protect overhead or underground power lines from faults. These fuses come in different voltage ratings and interrupting capacities, making it essential for engineers to evaluate the load conditions before selection. In contrast, substation fuses are used primarily in high-power substations and can handle larger fault currents. The 2022 Global Power Fuse Market Report indicates a growing trend towards the adoption of specialty fuses that cater to unique environments, such as those exposed to extreme temperatures or moisture, suggesting that customization is key in achieving optimal performance.

Understanding the specific requirements of your electrical system and how different Cooper Power Fuses serve those needs is vital. A 2023 study by the Institute of Electrical and Electronics Engineers (IEEE) highlights that an informed choice can not only protect equipment but also enhance energy efficiency by up to 15%, highlighting the importance of proper evaluation when selecting fuses for your electrical setup.

When it comes to the installation of Cooper Power Fuses, adhering to best practices is crucial for maximizing efficiency and ensuring the longevity of the system. According to the IEEE Power and Energy Society, improper installation can lead to a 15-20% increase in operational failures, which can significantly affect system reliability and performance. Therefore, following precise installation protocols can mitigate risks associated with fuse failure and enhance the overall operational efficiency of electrical systems.

One essential practice is to ensure that the fuses are correctly sized for their respective applications. The National Electrical Code (NEC) suggests that the fuse rating should correlate with the load’s maximum continuous current, typically set at 125% of the continuous load. Additionally, maintaining proper environmental conditions—such as ambient temperature and supporting structures—can further optimize performance. A study published by the Electric Power Research Institute (EPRI) notes that ensuring a temperature control of +20% to -10% of the rated ambient can prevent significant thermal events that could compromise fuse integrity. These proactive steps not only enhance the reliability of Cooper Power Fuses but also contribute to a more sustainable energy distribution network.

When working with Cooper power fuses, troubleshooting common issues is crucial for maintaining efficiency and safety in electrical systems. Data from the IEEE (Institute of Electrical and Electronics Engineers) indicates that improper fuse operation can lead to system failures, accounting for approximately 30% of electrical outages. Understanding how to identify and resolve these issues can significantly mitigate risks and downtime.

When working with Cooper power fuses, troubleshooting common issues is crucial for maintaining efficiency and safety in electrical systems. Data from the IEEE (Institute of Electrical and Electronics Engineers) indicates that improper fuse operation can lead to system failures, accounting for approximately 30% of electrical outages. Understanding how to identify and resolve these issues can significantly mitigate risks and downtime.

One frequent problem encountered with Cooper power fuses is incorrect fuse ratings. As per industry reports, using a fuse with an inadequate interrupting rating can result in catastrophic failures during fault conditions. Additionally, ensuring that the fuse is appropriately sized for the application is essential—research shows that mismatched fuses lead to overcurrent conditions and can damage sensitive electrical equipment. Regular inspections and testing, as recommended by ANSI/IEEE standards, help ensure fuses are functioning correctly and within their specified limits, thereby enhancing overall system reliability.

Maintaining Cooper Power fuses is critical for ensuring their longevity and optimal performance in electrical distribution systems. With their reliability as a cornerstone for power reliability, regular maintenance can significantly extend their lifespan. According to industry reports, proper maintenance of fuses can increase their operational lifespan by up to 30%. This makes it essential to implement effective maintenance practices tailored to the specific requirements of Cooper Power fuses.

To promote the longevity of these fuses, consider these essential tips:

First, conduct regular visual inspections to check for signs of wear or corrosion. Fuses that are exposed to harsh environmental conditions may require more frequent assessments.

Second, ensure that connection points are secure and free of dirt or moisture, as these can lead to electrical failures.

Lastly, maintain accurate operational records, tracking performance and replacement schedules, to help anticipate issues before they arise.

Moreover, it’s crucial to adhere to manufacturer guidelines, such as using the correct fuse rating for your application. A 2021 report from the Electrical Safety Foundation International states that improperly rated fuses account for nearly 15% of electrical faults. By following these guidelines and adhering to best practices, you can optimize the performance of Cooper Power fuses, ensuring efficient and reliable electrical distribution.