-

Home

-

About Us

-

Products

-

News

-

Blog

-

Contact Us

Leave Your Message

In electrical systems, the management of voltage levels is crucial for ensuring safety, efficiency, and reliability. Among the various protective devices used, a Medium Voltage Fuse plays a pivotal role. These fuses are specifically designed to protect equipment from overcurrents and short circuits within the medium voltage range, typically between 1 kV and 36 kV. Understanding how a Medium Voltage Fuse operates is essential for electrical engineers and technicians, as it helps mitigate risks associated with electrical faults and facilitates seamless operation in industrial and commercial settings.

The functionality of a Medium Voltage Fuse involves a simple yet effective mechanism: when excessive current flows through the fuse, it causes the fuse element to heat up and melt, thereby interrupting the circuit. This characteristic not only safeguards the connected equipment but also prevents potential hazards like electrical fires and equipment damage. Additionally, the selection and installation of the appropriate fuse type are critical, as they must match the specific application requirements to provide optimal protection. Through this exploration of Medium Voltage Fuses, we aim to shed light on their significance in electrical systems and how they contribute to the overall safety and efficiency of power distribution networks.

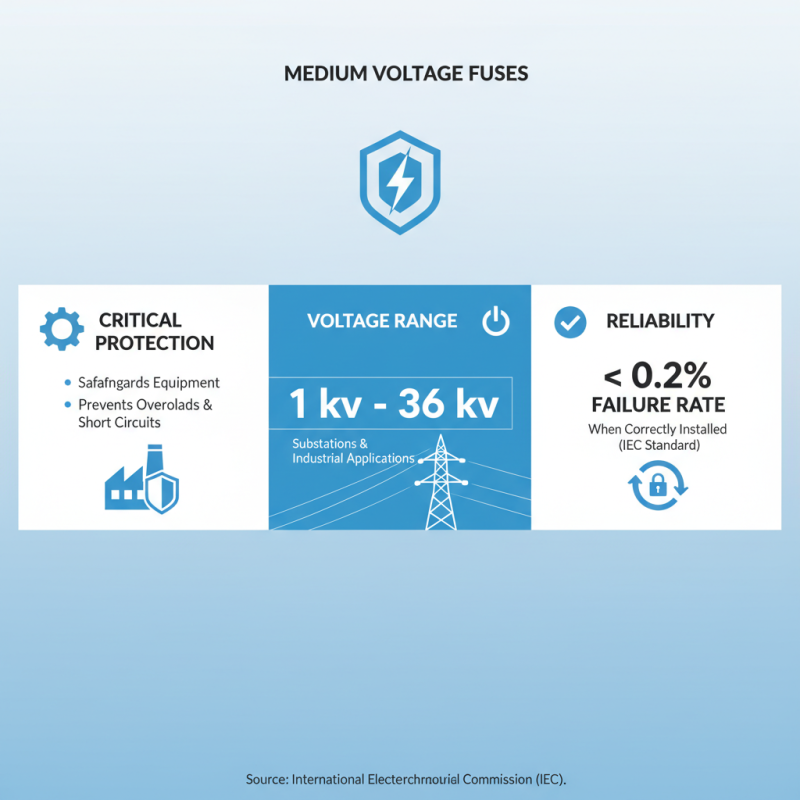

A medium voltage fuse is a critical component in electrical systems, primarily used to protect equipment and infrastructure from overloads and short circuits. Operating typically within the voltage range of 1 kV to 36 kV, these fuses play a crucial role in ensuring the safety and reliability of power distribution networks. According to the International Electrotechnical Commission (IEC), medium voltage fuses account for a significant portion of protection devices in substations and industrial applications, with a failure rate of less than 0.2% when correctly installed.

The primary function of a medium voltage fuse is to interrupt excessive currents caused by faults, thereby preventing potential damage to transformers, feeders, and other electrical equipment. When an overcurrent occurs, the fuse element—usually made of a metal alloy—melts at a predetermined temperature, effectively breaking the circuit. This action not only safeguards the equipment but also contributes to the stability and resilience of the entire electrical grid. Industry reports indicate that the implementation of proper medium voltage fuse technology can enhance system reliability by up to 30%, reducing unplanned downtimes and maintenance costs significantly, making it an invaluable asset in modern power systems.

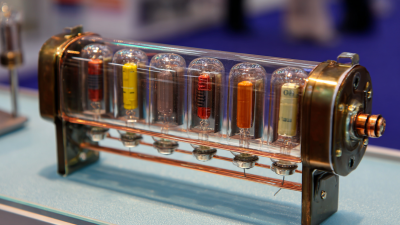

Medium voltage fuses play a crucial role in protecting electrical systems from overloads and short circuits. The key components of these fuses include the fuse element, the housing, and the arc quenching medium. The fuse element is typically made of a metal conductor that melts when excessive current flows through it, interrupting the circuit. This element is housed in a sturdy casing designed to withstand environmental conditions, while facilitating easy replacement when necessary. The selection of materials for both the fuse element and housing is critical, as they must ensure reliability and enhance the fuse’s performance.

Another essential design feature of medium voltage fuses is the arc extinguishing mechanism, which prevents the continuation of current after the fuse element melts. This is achieved through various methods, including the use of sand or gas, which helps to cool and quench the electrical arc generated during the fuse's operation. Additionally, many medium voltage fuses are designed with a visual indication feature that allows operators to easily determine the fuse status, ensuring quick maintenance and reduced downtime. The integration of these components and designs ensures that medium voltage fuses operate effectively, providing both protection and reliability in electrical systems.

Medium voltage fuses are essential components in electrical systems, designed to protect circuits from overloads and short circuits. Their operation relies on specific mechanisms that ensure rapid response to fault conditions. When an excessive current flows through the fuse due to a fault, the fuse element, typically made of a metal conductor, heats up. This heat generation is a result of the electrical resistance encountered by the current. When the temperature reaches a certain threshold, the fuse element melts, interrupting the current flow and thereby protecting the rest of the electrical circuit from damage.

The design of medium voltage fuses incorporates various features that enhance their protective capabilities. For instance, many fuses include a clear tube filled with sand or another insulating material, which helps to quench the arc that forms when the fuse element melts. This quenching process is crucial as it prevents the arc from causing further damage and allows for a quicker restoration of the system once the fuse is replaced.

Additionally, medium voltage fuses can be rated for different current levels and voltages, ensuring precise protection tailored to the specific requirements of the electrical network in which they are installed. Through these mechanisms, medium voltage fuses play a vital role in maintaining the reliability and safety of electrical systems.

Medium voltage fuses are crucial components in electrical systems, designed to protect equipment by interrupting excess current flow. Understanding the industry standards and ratings for these fuses is essential for ensuring their effective application in various settings. The specifications are typically classified based on voltage rating, current rating, and breaking capacity. Voltage ratings ensure the fuse can handle the operating conditions of the system, while current ratings indicate the maximum continuous current the fuse can allow before it blows.

Furthermore, breaking capacity denotes the maximum fault current that the fuse can safely interrupt without a risk of failure. This parameter is critical in applications where unexpected surges in current are likely. Compliance with recognized standards such as those set by the International Electrotechnical Commission (IEC) or the Institute of Electrical and Electronics Engineers (IEEE) helps manufacturers and users ensure that the fuses will operate correctly under specified conditions. Overall, a thorough understanding of these ratings and standards is vital for selecting the appropriate medium voltage fuse for any electrical application, ensuring reliability and safety in operation.

This bar chart illustrates the amperage ratings commonly used for medium voltage fuses, showcasing the different voltage levels and their respective fuse ratings. Understanding these ratings is essential for ensuring proper protection in electrical systems.

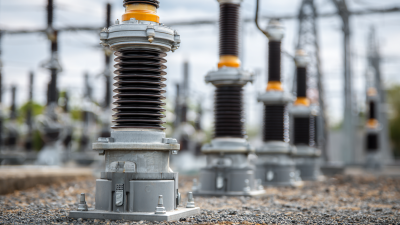

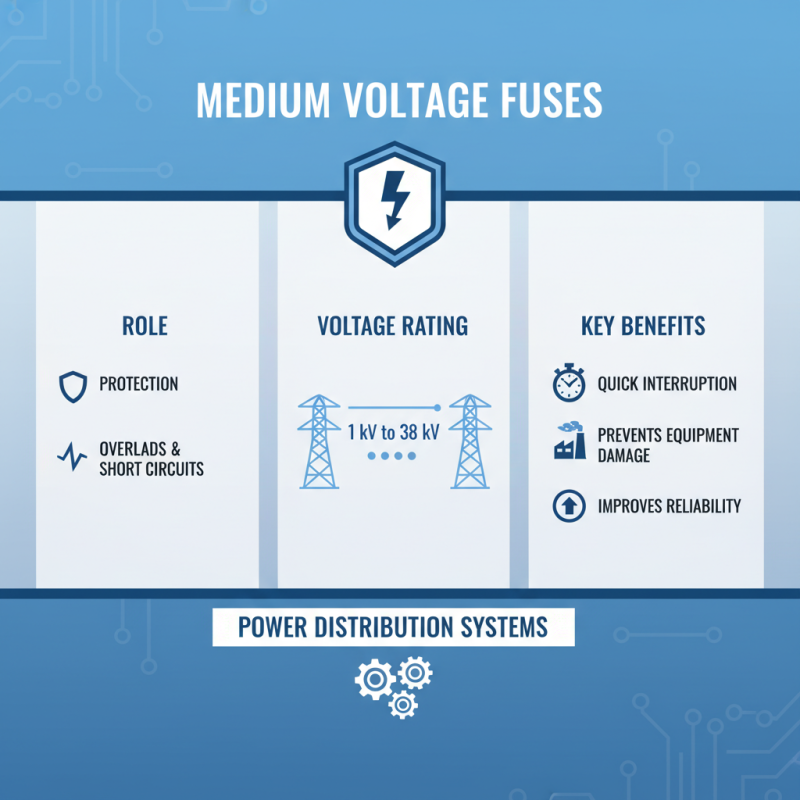

Medium voltage fuses play a crucial role in power distribution systems by protecting electrical equipment from overloads and short circuits. Typically rated between 1 kV and 38 kV, these fuses are designed to interrupt excessive currents quickly, preventing damage to transformers, generators, and other critical components. Their ability to operate efficiently in medium voltage applications makes them indispensable in industrial and commercial electrical networks where reliability is paramount.

The applications of medium voltage fuses are widespread, ranging from substations to various industrial settings. They are commonly used to protect distribution transformers, capacitor banks, and motor circuits. In addition to safeguarding equipment, medium voltage fuses enhance system reliability by isolating faulted sections from healthy ones, allowing for continued operation of unaffected areas. This targeted interruption not only minimizes downtime but also ensures safety by preventing the spread of electrical faults throughout the system. Ultimately, the integration of medium voltage fuses in power distribution networks contributes significantly to efficiency and reliability in electrical systems.