-

Home

-

About Us

-

Products

-

News

-

Blog

-

Contact Us

Leave Your Message

Understanding the function of a Power Transformer Fuse is crucial for anyone in the electrical industry. These fuses protect transformers from overloads and faults. The right fuse type can prevent costly damages and enhance the efficiency of power systems.

Different fuse types have distinctive characteristics. For example, some fuses respond quickly to short circuits, while others are designed for high-current applications. Knowing your options is essential. This knowledge can lead to better decisions that impact safety and performance.

Recognizing the importance of these fuses is not just technical. It requires careful consideration of specific situations and power requirements. Improper choices may lead to failures. There’s always room for improvement and learning in this field. Understanding Power Transformer Fuse types enhances both knowledge and practice. Being informed empowers professionals to make better choices.

Power transformer fuses play a crucial role in electrical systems. They protect transformers from overcurrent and short circuits. Understanding the types of fuses can help you choose the right one for your needs. According to industry reports, over 30% of transformer failures are due to electrical faults. Fuses can prevent these failures by interrupting excess current.

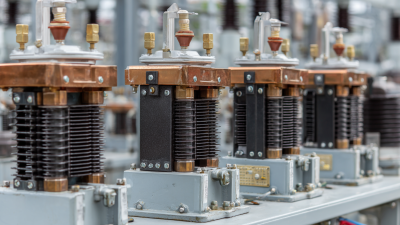

There are several types of power transformer fuses. Current limiting fuses operate quickly, reducing peak currents and damage. Expulsion fuses, on the other hand, are simpler and contain a low-cost design. They work effectively in outdoor environments. The choice depends on the application and specific requirements. Many engineers recommend careful evaluation to choose the right fuse type.

In some cases, fuses can fail. Aging can lead to reduced effectiveness. Also, improper installation can compromise their function. Regular checks are advised to ensure reliability. Data shows that around 15% of electrical faults result from fuse failures. Thus, understanding the limitations of fuses is key for maintenance and safety.

Fuses play a critical role in power transformers. They protect against faults and overloads. Without proper fuses, transformers face serious risks. A fuse acts as a safety valve. It interrupts the circuit when excess current flows. This simple device prevents costly damage.

Different fuse types serve various needs. For instance, current-limiting fuses quickly cut off the supply. Other types, like expulsion fuses, offer a simple design. However, they may not always react fast enough. Each type has its pros and cons. Choosing the correct fuse requires careful consideration.

Neglecting fuse management can lead to failures. Over time, fuses can degrade and lose effectiveness. Regular inspection is vital. Monitoring operational conditions helps ensure fuses are in good shape. A blown fuse may seem trivial but can have far-reaching effects. Power transformers depend on these components for safety.

When it comes to power transformers, selecting the right fuse type is crucial. Understanding fuse types can prevent severe outages. Here's a closer look at five common types of power transformer fuses.

One of the most used fuse types is the expulsion fuse. Its design allows for quick interruption of faults. Typically made with a ceramic casing, these fuses are reliable in outdoor settings. The expulsion fuse can withstand high voltage levels, making it ideal for many applications. However, it requires regular maintenance to ensure functionality.

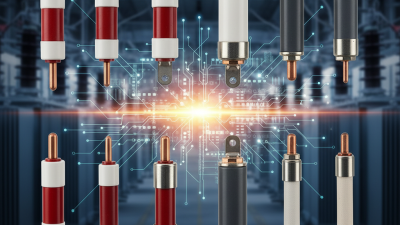

Another option is the current-limiting fuse. These fuses protect transformers by limiting fault currents. They react quickly and can prevent damage to electrical components. A study suggested that using current-limiting fuses can reduce equipment failure rates by up to 30%. Keep in mind, this type may not be suitable for every situation.

Tips: Regularly inspect all fuses for signs of wear. Test functionality to ensure efficiency. Sometimes, minor issues lead to major failures.

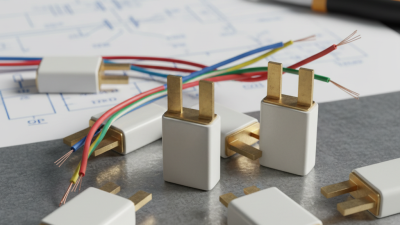

Lastly, consider the fuse link type. It's simple but effective. These are often chosen based on specific current ratings. Users should always verify compatibility with transformer specifications. Avoiding shortcuts in fuse selection is essential.

When it comes to power transformer fuses, understanding different types is essential. Each fuse type has unique features and benefits that cater to varying applications. The current-limiting fuse is popular due to its ability to quickly interrupt short circuits. It minimizes damage and improves system reliability. Operators often prefer this type for its protective characteristics.

Another common choice is the expulsion fuse. These fuses work well in outdoor environments. They are simple and cost-effective. However, they may not always provide the best protection under certain conditions. Engineers must assess the environment carefully before opting for this solution.

Lastly, there’s the semiconductor fuse. This type offers high precision and quick response to overloads. It’s ideal for sensitive equipment, yet it may require more regular maintenance. Finding the right balance between performance and cost is often challenging. Understanding these nuances can lead to better decisions in fuse selection without compromising safety.

When it comes to transformer fuses, proper installation and maintenance are critical. Incorrectly installed fuses can lead to system failures. It’s essential to ensure they fit well and are securely connected. Regular inspections can prevent issues before they arise. The physical layout of the installation area can impact fuse efficiency. Keep that area clean and free of obstructions.

Tips: Always check for signs of wear or damage on fuses. A simple visual inspection can save time and money. Ensure that the rating of the fuse aligns with the transformer’s capacity. Mismatched ratings lead to overheating or frequent blowouts. It’s an easy detail to overlook, but crucial for system integrity.

Maintenance should include periodic testing. Testing ensures that fuses work under load conditions. If you find inconsistent performance during tests, it’s time for replacement. Be aware, however, that not all aging fuses need immediate replacement. Sometimes, a fuse can be visually intact but may not perform well under stress. Continuous monitoring is key for maintaining optimal system operations.