-

Home

-

About Us

-

Products

-

News

-

Blog

-

Contact Us

Leave Your Message

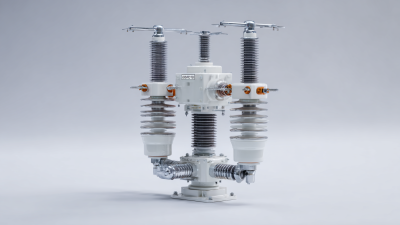

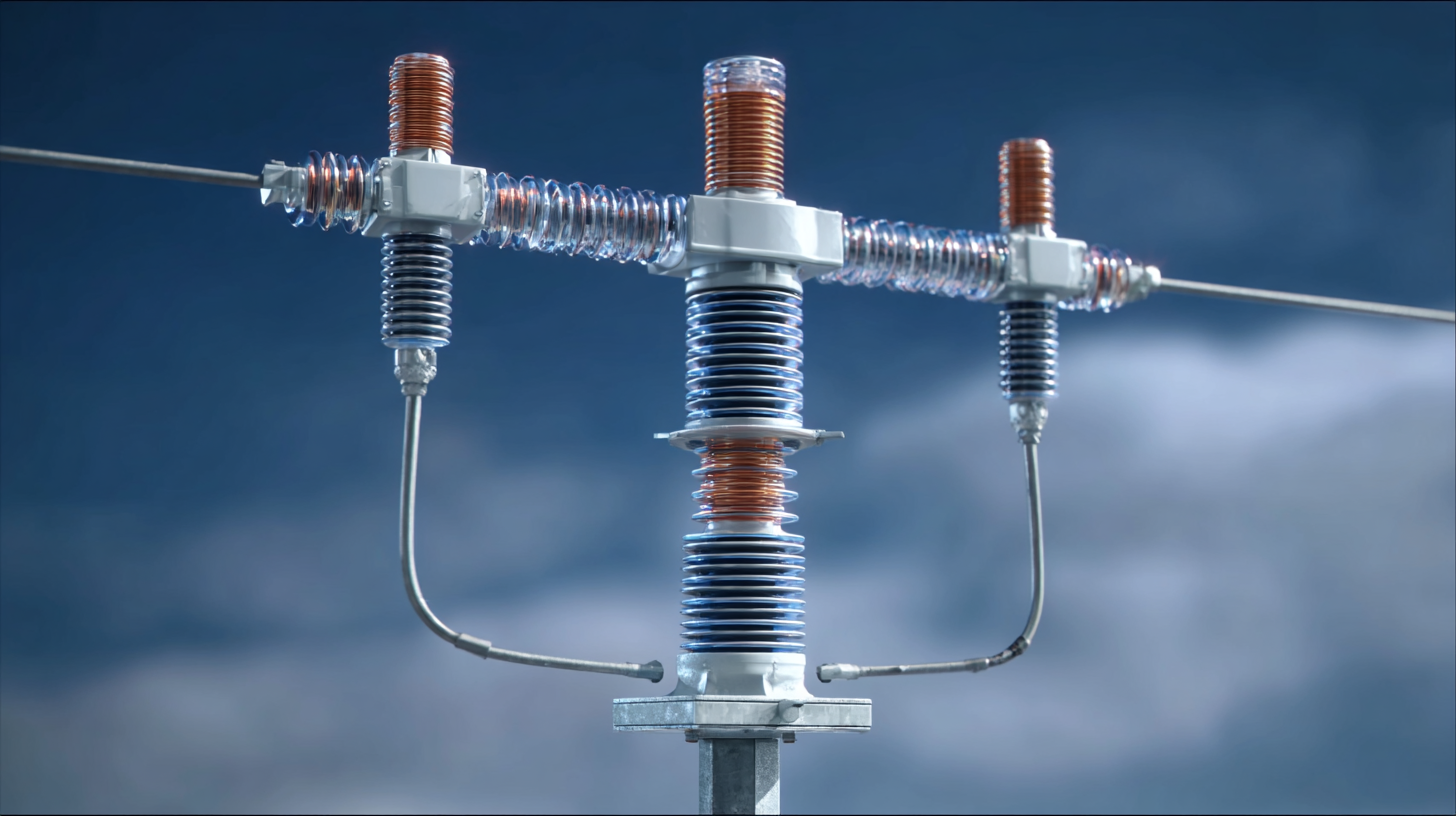

In an era where electrical safety is paramount, the innovative introduction of Silicone Rubber Arresters is revolutionizing the industry. According to a report by MarketsandMarkets, the global electrical insulation market is projected to reach USD 61.4 billion by 2025, driven by the increasing demand for advanced safety solutions.

Silicone Rubber Arresters, known for their exceptional dielectric properties and resistance to environmental factors, are poised to play a crucial role in this growth. With their ability to withstand extreme temperatures and enhance operational reliability, these devices not only protect electrical systems from voltage surges but also extend their lifespan significantly.

The adoption of Silicone Rubber Arresters in various electrical applications underscores a pivotal shift towards more resilient infrastructure, addressing the pressing need for enhanced safety measures in the increasingly electrified world.

Silicone Rubber Arresters, known for their exceptional dielectric properties and resistance to environmental factors, are poised to play a crucial role in this growth. With their ability to withstand extreme temperatures and enhance operational reliability, these devices not only protect electrical systems from voltage surges but also extend their lifespan significantly.

The adoption of Silicone Rubber Arresters in various electrical applications underscores a pivotal shift towards more resilient infrastructure, addressing the pressing need for enhanced safety measures in the increasingly electrified world.

Silicone rubber arresters play a crucial role in enhancing electrical safety, particularly as the demand for reliable electrical systems continues to rise. These devices are designed to protect electrical equipment from voltage surges, which can occur due to lightning strikes or switching operations. The growing emphasis on infrastructure and renewable energy sources has increased the demand for effective surge protection solutions. According to recent industry reports, the polymer surge arrester market is projected to surpass USD 904.8 million by 2024, with a compound annual growth rate (CAGR) of 5.4% expected from 2025 to 2034. This indicates a significant shift towards advanced materials like silicone rubber in surge protection systems.

The unique properties of silicone rubber, including its excellent electrical insulation and resistance to extreme weather conditions, make it an ideal choice for arresters. As utility companies and industries seek to minimize downtime and enhance operational reliability, silicone rubber arresters are becoming a preferred solution. They not only offer enhanced safety through effective voltage clamping but also contribute to the longevity of electrical equipment by preventing surge-related damages. As the market evolves, it will be fascinating to see how these innovations in silicone rubber technology further revolutionize electrical safety.

Silicone rubber arresters are emerging as a pivotal innovation in the field of electrical safety, offering numerous advantages over traditional materials. One of the primary benefits lies in their superior thermal stability. According to a recent study by the Electric Power Research Institute (EPRI), silicone rubber can withstand temperatures ranging from -60°C to 180°C without significant degradation, making it ideal for outdoor applications where environmental conditions can be extreme. This thermally resilient property ensures that silicone rubber arresters maintain their performance and integrity longer than conventional rubber or polymer products.

In addition to temperature resilience, silicone rubber arresters exhibit exceptional dielectric strength, measured at around 20 kV/mm, as reported by the International Electrotechnical Commission (IEC). This high level of electrical insulation reduces the risk of breakdown and enhances the overall safety of electrical systems. Furthermore, silicone rubber is inherently hydrophobic, providing excellent water repellency. This characteristic minimizes the risk of moisture-related failures, which are a common concern with traditional materials, particularly in areas prone to rainfall or humidity. The combination of these benefits positions silicone rubber arresters as a revolutionary choice for electrical safety applications, promising a more reliable and durable solution for the industry.

| Feature | Silicone Rubber Arresters | Traditional Materials |

|---|---|---|

| Temperature Resistance | -60°C to 200°C | -40°C to 90°C |

| Electrical Insulation | Excellent | Good |

| Aging Resistance | High | Medium |

| Chemical Resistance | Excellent | Limited |

| Flexibility | High | Lower |

| Weight | Lightweight | Heavier |

| Cost | Moderately Priced | Generally Lower |

| Impact Resistance | Superior | Average |

Proper installation of silicone rubber arresters in electrical systems is crucial for enhancing safety and performance. These arresters serve as vital components in mitigating voltage spikes, effectively protecting sensitive electrical equipment from potential damage. When installing silicone rubber arresters, it's essential to ensure they are placed at strategic points within the electrical system, typically near the source of electrical supply and close to equipment that is susceptible to surge damage.

When installing these devices, start by assessing the electrical setup to determine the best locations for placement. The arresters should be securely mounted and connected to the electrical grounding system to ensure maximum effectiveness. Additionally, it is important to verify that all connections are tight and that the materials used are compatible with the existing electrical infrastructure to maintain integrity under varying environmental conditions. Regular maintenance checks should be conducted to confirm the arresters are functioning properly, especially after severe weather events, similar to how heavy dampers protect skyscrapers against strong winds and typhoons. This proactive approach ensures that electrical systems remain safe, efficient, and free from damaging surges.

When installing these devices, start by assessing the electrical setup to determine the best locations for placement. The arresters should be securely mounted and connected to the electrical grounding system to ensure maximum effectiveness. Additionally, it is important to verify that all connections are tight and that the materials used are compatible with the existing electrical infrastructure to maintain integrity under varying environmental conditions. Regular maintenance checks should be conducted to confirm the arresters are functioning properly, especially after severe weather events, similar to how heavy dampers protect skyscrapers against strong winds and typhoons. This proactive approach ensures that electrical systems remain safe, efficient, and free from damaging surges.

Silicone rubber arresters play a crucial role in enhancing the safety and reliability of electrical systems, particularly in mitigating the effects of over-voltage surges. To maintain their effectiveness, regular inspection and maintenance practices are essential. According to the IEEE (Institute of Electrical and Electronics Engineers), nearly 70% of equipment failures can be traced back to inadequate maintenance protocols. This statistic underscores the importance of routine checks on silicone rubber arresters, ensuring they remain functional in preventing potential electrical hazards.

Best practices for maintaining silicone rubber arresters include conducting visual inspections at least bi-annually. Inspectors should look for any signs of wear, such as cracking or discoloration, typically caused by environmental factors like UV exposure or extreme temperatures. Additionally, it's recommended to perform insulation resistance testing, as research by the Electrical Safety Foundation International indicates that up to 40% of electrical hazards can be eliminated through proper diagnostic evaluations. Keeping detailed records of inspections and any maintenance performed helps in tracking the performance of arresters over time, ultimately ensuring the safety of electrical applications.

Silicone rubber arresters are becoming essential in various industries, particularly in electrical applications, due to their unique properties that enhance safety and reliability. These materials are known for their excellent insulation characteristics, resistance to heat, and durability, making them ideal for environments where electrical safety is paramount. For instance, in the automotive industry, silicone rubber arresters are employed to protect sensitive electronic components from voltage surges and environmental extremes, thereby extending the lifespan of critical electrical systems.

Silicone rubber arresters are becoming essential in various industries, particularly in electrical applications, due to their unique properties that enhance safety and reliability. These materials are known for their excellent insulation characteristics, resistance to heat, and durability, making them ideal for environments where electrical safety is paramount. For instance, in the automotive industry, silicone rubber arresters are employed to protect sensitive electronic components from voltage surges and environmental extremes, thereby extending the lifespan of critical electrical systems.

In industrial settings, silicone rubber arresters play a crucial role in machinery and equipment protection. They mitigate risks associated with electrical faults, ensuring operational safety and efficiency. Their flexibility and strength also make them suitable for use in construction and telecommunications, where they help manage electrical signaling and prevent equipment failure. As industries increasingly prioritize safety and sustainability, the adoption of silicone rubber arresters will likely expand, further revolutionizing how safety is approached in complex electrical applications.