-

Home

-

About Us

-

Products

-

News

-

Blog

-

Contact Us

Leave Your Message

In the realm of electrical safety, the significance of the Fuse of Transformer cannot be overstated. According to the International Electrotechnical Commission (IEC), electrical faults account for approximately 30% of all fire incidents worldwide, emphasizing the need for robust protective measures. The Fuse of Transformer plays a crucial role in ensuring that electrical systems operate safely by preventing overloads and short circuits, which can lead to catastrophic failures. As reported by the National Fire Protection Association (NFPA), proper fuse installation and maintenance can significantly reduce the risk of electrical fires, with an estimated 60% of transformer-related incidents being avoidable through effective fuse utilization. Understanding the function and importance of the Fuse of Transformer is essential for electrical engineers and safety professionals alike, as it serves as a first line of defense against potentially hazardous electrical anomalies.

Fuses play a crucial role in the safety mechanisms of transformers, acting as a primary line of defense against electrical faults. According to the National Fire Protection Association (NFPA), approximately 23% of all electrical fires are due to equipment failure, with transformers being a significant contributor. Fuses help prevent overcurrent conditions that can lead to insulation breakdown and catastrophic failures, ultimately protecting both equipment and personnel.

When selecting fuses for transformer applications, it's vital to consider the current rating and response time. For instance, a fast-acting fuse may be necessary for sensitive electrical components, while a time-delay fuse can handle inrush currents without tripping. According to a report by the Electrical Safety Foundation International (ESFI), implementing proper fuse selection and maintenance can reduce electrical incidents by nearly 30%.

Tips: Regular maintenance inspections are essential. Ensure fuses are checked for signs of wear and tear, and replace any that show signs of damage. Additionally, always consult the transformer manufacturer’s guidelines to ensure compatibility and enhance overall safety. Keeping backup fuses on hand can also streamline emergency responses and reduce downtime in critical situations.

Fuses play a critical role in maintaining electrical safety within transformer systems, particularly as instances of transformer failures become more common due to various underlying issues. For instance, a recent study highlighted that many transformers in Bengaluru are poorly maintained, increasing their susceptibility to failures that can significantly disrupt the power supply. Such degradation emphasizes the importance of fuses, which are designed to provide a protective mechanism that disconnects the power in the event of overloads or faults, thereby preventing further damage to the transformer and ensuring the safety of the overall electrical system.

Moreover, statistics reveal that transformers are expected to have a useful life of approximately 25-30 years; however, many experience premature failures. In locations facing higher temperatures, such as the recent cases in Patna where power demand peaked at record levels amidst severe heat conditions, fuses serve as a first line of defense to protect transformers from overload situations that could otherwise lead to costly outages. By leveraging advancements in technology, including machine learning for monitoring transformer health, utilities can enhance their predictive maintenance strategies, minimizing failures and ensuring the reliability of power distribution networks.

This chart illustrates the common causes of transformer failures and highlights the importance of fuses in protecting electrical systems. The primary failure types include overheating, insulation breakdown, and electrical faults, which can all be mitigated by using appropriate fuses.

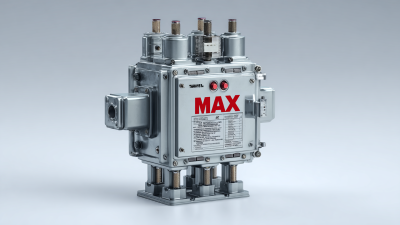

Fuses play a crucial role in enhancing the safety and reliability of transformers. They serve to protect these vital components from overloads and fault conditions. There are several types of fuses used in transformers, each offering unique advantages that cater to different operational scenarios. One of the most commonly used is the current-limiting fuse, which quickly interrupts excessive current flow while minimizing damage. This type of fuse is particularly effective in reducing the impact of short circuits, safeguarding not only the transformer itself but also the connected electrical systems.

Another type of fuse worth noting is the drop-out fuse, which is often employed in outdoor transformer applications. It is designed to disconnect the transformer from the power line when a fault occurs, ensuring immediate isolation to prevent further damage. This particular fuse is advantageous in that it allows for easy maintenance and replacement without the need for additional tools or equipment. By understanding the various types of fuses and their benefits, operators can make informed decisions to enhance the protection and longevity of transformers within their electrical systems.

Maintaining fuses in electrical systems is crucial for ensuring safety and efficiency. According to the National Fire Protection Association (NFPA), electrical failures contribute to over 25% of structure fires in the United States, highlighting the vital role that properly functioning fuses play in reducing these risks. Regular inspection and maintenance of fuses can prevent overloads and potential short circuits, which are common causes of electrical fires. It is recommended to check fuses monthly to ensure they are intact and free from corrosion, as faulty fuses can lead to significant safety hazards.

Best practices for maintaining fuses include adhering to the manufacturer’s specifications for fuse ratings and replacement schedules. The Institute of Electrical and Electronics Engineers (IEEE) suggests that all electrical systems should have a fuse replacement plan based on usage patterns and environmental conditions. Additionally, implementing a routine testing procedure can help identify weak points in the electrical system before they lead to system failure. Studies indicate that systems with regular maintenance checks have a 30% lower failure rate compared to those without scheduled evaluations. By prioritizing these practices, professionals can enhance both the safety and reliability of electrical installations.

When it comes to ensuring the safety of transformers, understanding

fuse ratings is crucial. Fuses act as the first line of defense against electrical faults,

protecting transformers from overload and short circuits. The rating of a fuse must align with the

transformer's capacity and operational parameters. An incorrectly rated fuse can either blow too frequently,

causing unnecessary downtime, or fail to protect the transformer during a fault condition.

Tip: Always consult the manufacturer's specifications for both the transformer and fuses.

This alignment ensures that the system can handle expected currents without risking damage or interruption.

Additionally, consider environmental factors when selecting fuse ratings. Temperature fluctuations, humidity,

and altitude can affect fuse performance. Choosing a fuse with a rating that accounts for these variables can

enhance the reliability and safety of your electrical setup.

Tip: Regular maintenance and testing of fuse integrity should be scheduled, ensuring they

maintain operational efficacy. Regular checks can prevent unexpected failures and enhance overall system stability,

safeguarding your investment in transformers.