-

Home

-

About Us

-

Products

-

News

-

Blog

-

Contact Us

Leave Your Message

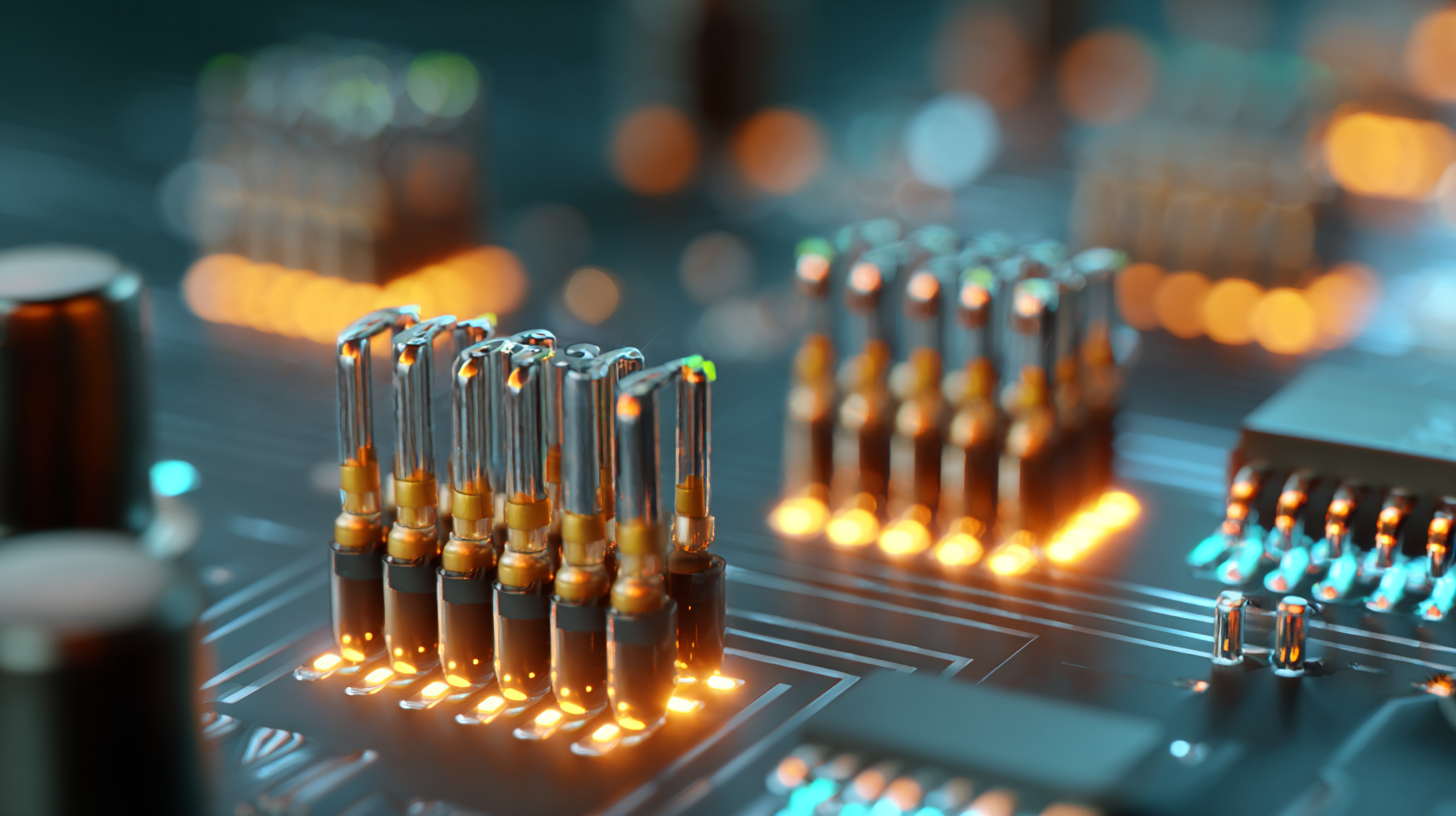

The advancement of modern electronics has significantly shaped various industries, with innovations continuously pushing the boundaries of technology. Among these innovations, the Pt Fuse has emerged as a critical component, particularly in safeguarding sensitive electronic circuits against overcurrent conditions. According to a report by MarketsandMarkets, the global fuse market is projected to reach USD 2.6 billion by 2025, driven by the increasing demand for reliable and efficient electronic devices. As devices become more compact and powerful, the role of the Pt Fuse in ensuring durability and performance is paramount.

This introduction explores the pivotal functions of Pt Fuses within contemporary electronic systems, highlighting their applications in sectors ranging from consumer electronics to automotive industries, and discusses how their unique properties contribute to enhanced reliability and safety in an ever-evolving technological landscape.

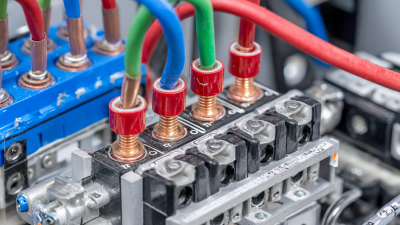

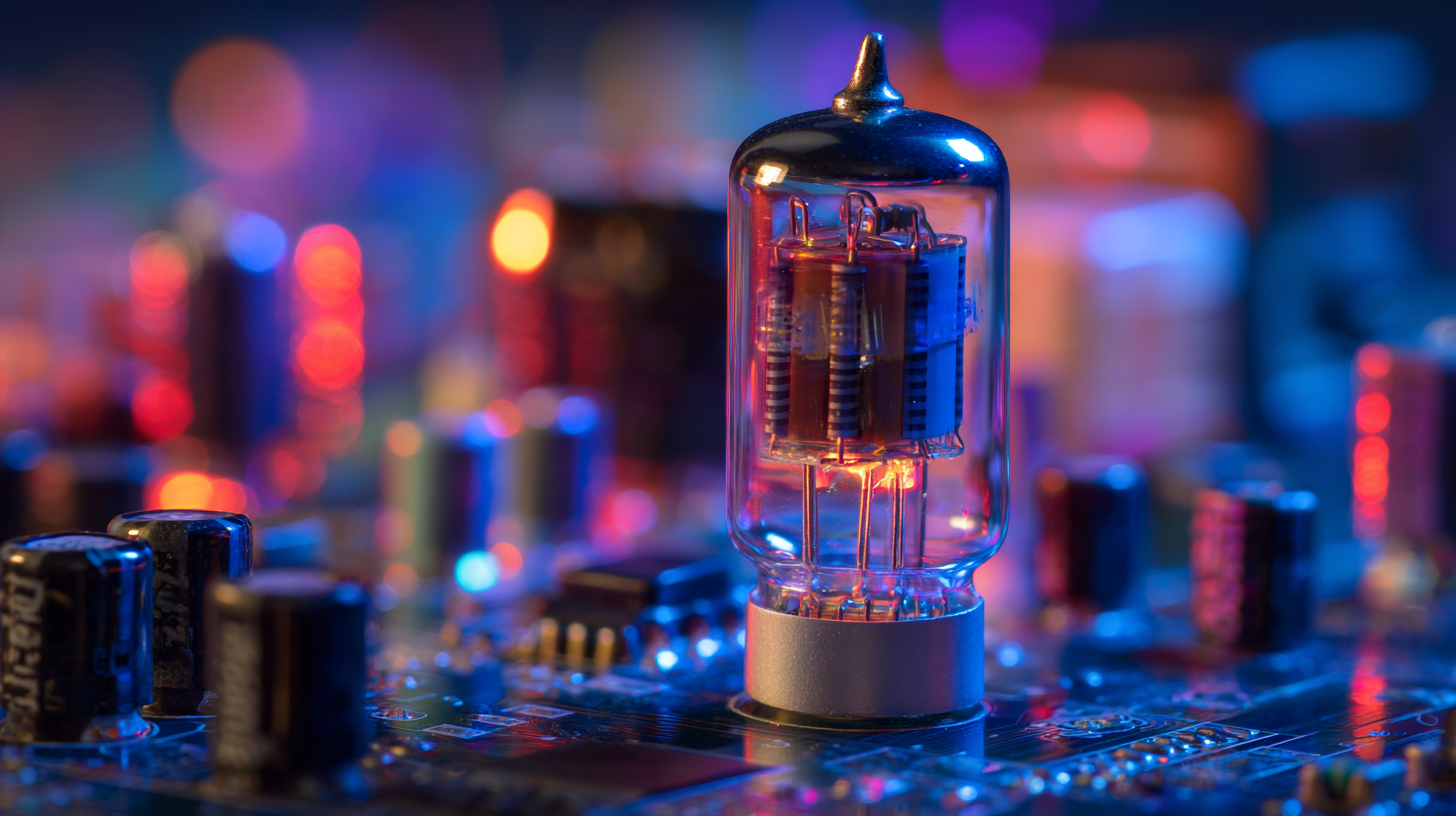

Platinum fuses are emerging as critical components in modern electronics, primarily due to their exceptional properties that enhance performance and reliability in electronic applications. Understanding the fundamental properties of Pt fuses reveals their unique capabilities in handling high currents, providing superior thermal stability, and ensuring rapid response to overcurrent conditions. These attributes make Pt fuses ideal for safeguarding sensitive electronic components and systems, enabling them to function safely and effectively in various environments.

Recent advancements in computational studies have mapped the intricate relationships between structure and properties in various materials, including carbon nanomaterials like fullerenes, which parallel the innovations seen in Pt fuse technology. This research indicates that structural diversity plays a pivotal role in determining material performance. Similarly, the exploration of novel phenomena such as valleytronics further highlights the continued evolution of electronic applications. By examining the underlying properties that govern the behavior of materials at the nanoscale, researchers can pave the way for innovative electronic devices that leverage both the unique properties of Pt fuses and the advances in material science to create more efficient and powerful systems.

The integration of Pt fuses in modern electronics is steadily evolving, driven by the need for enhanced safety and efficiency in semiconductor applications. As the industry witnesses innovations in wafer-level packaging (WLP) technology, the role of Pt fuses becomes increasingly crucial. Research indicates that WLP is expected to significantly reduce warpage issues in semiconductor applications while facilitating heterogeneous integration. This reduction enhances the reliability of circuitry, making the incorporation of Pt fuses a strategic necessity.

When considering innovative design strategies for integrating Pt fuses into circuits, it is vital to leverage insights from the growing global integrated circuit market, projected to reach USD 1924.17 billion by 2033. This growth is particularly pronounced in the Asia-Pacific region, which demonstrates a robust manufacturing infrastructure. Therefore, designers must explore collaborations that leverage local manufacturing capabilities while incorporating advanced features of Pt fuses to improve safety and performance.

Tips:

1. Utilize simulation software to model circuit layouts before physical integration; this practice can help identify potential issues early on.

2. Stay updated on advancements in semiconductor technologies to ensure design strategies align with the latest trends and best practices within the industry.

The innovative use of Pt fuses in modern electronics significantly enhances device performance and protection. According to a recent industry report by MarketsandMarkets, the global fuse market is projected to reach USD 10.1 billion by 2025, with a notable shift towards platinum-based solutions. Pt fuses offer superior current interruption capabilities, high thermal stability, and minimal energy loss, reinforcing their necessity in advanced electronic designs. These properties allow for smaller, more efficient devices that can handle increased power demands without compromising safety.

**Tip:** When designing circuits that utilize Pt fuses, ensure that the fuse rating aligns with the peak operational current to optimize performance and safeguard sensitive components.

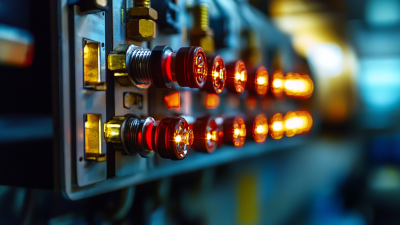

Furthermore, the ability of Pt fuses to operate effectively across a broad temperature range makes them ideal for applications in automotive, aerospace, and consumer electronics. The International Electrotechnical Commission (IEC) notes that the failure rate in electronic devices can be reduced by up to 30% when employing higher quality fuses, such as Pt varieties. This enhancement not only prolongs the life of electronic devices but also boosts reliability, making Pt fuses a crucial element in the design of cutting-edge technology.

**Tip:** Regular testing and evaluation of fuse performance can provide insights into potential improvements and ensure that devices maintain their integrity under varying operational conditions.

| Application Area | Advantage of Pt Fuse | Performance Metrics | Typical Use Case |

|---|---|---|---|

| Consumer Electronics | Improved Overload Protection | Response Time: < 1 ms | Smartphones and Tablets |

| Automotive | Increased Safety and Reliability | Operating Temperature: -40 to 125 °C | Electrical Systems in Vehicles |

| Industrial Equipment | Enhanced Power Management | Current Rating: Up to 60 A | Manufacturing Machines |

| Telecommunications | High-Quality Signal Integrity | Failure Rate: < 0.1% | Network Equipment |

| Medical Devices | Critical Protection for Sensitive Equipment | Compliance: ISO 13485 | Diagnostic Machines |

The growing reliance on electronic devices has amplified concerns regarding electronic waste (e-waste) and its environmental impact. Platinum (Pt) fuses are becoming increasingly prevalent in modern electronics, valued for their reliability and efficiency. However, the disposal of electronic devices containing Pt fuses poses a significant challenge. When improperly discarded, these fuses can contribute to environmental degradation, releasing harmful substances into soil and waterways. This highlights the critical need for effective recycling programs that address the specific materials used in electronic components, including Pt fuses.

Sustainability in electronics is not just about the materials themselves but also about the lifecycle of these devices. As manufacturers innovate to create more efficient electronic systems, they also have a responsibility to implement recycling initiatives. By promoting proper disposal and encouraging the recovery of precious metals like platinum, the industry can minimize the negative environmental impact associated with e-waste. Transitioning to a circular economy, where valuable materials are reclaimed and reused, is essential for reducing the ecological footprint of electronic products containing Pt fuses.

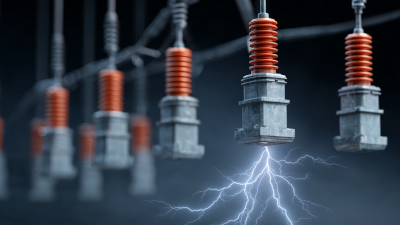

The future of electronics is increasingly intertwined with innovative uses of materials like platinum (Pt) fuses. As the demand for miniaturization and efficiency rises, industries are exploring advanced technologies that utilize Pt fuses to enhance performance and reliability. With their superior conductive properties and resistance to oxidation, Pt fuses are poised to play a pivotal role in applications such as high-frequency circuits and sophisticated power management systems. This trend aligns with the growing focus on sustainability, where the longevity and reusability of components are paramount.

Emerging technologies in electric vehicles (EVs) and renewable energy systems are set to leverage the distinctive benefits of Pt fuses. In EVs, the reduction of weight and size without compromising safety is critical, and Pt fuses can help achieve this by providing reliable overcurrent protection in compact forms. Furthermore, as smart grids and intermittent energy sources like solar and wind become more prevalent, Pt fuses will be instrumental in managing electrical loads and enhancing the overall stability of energy systems. The exploration of these applications indicates a significant shift towards integrating advanced materials into the fabric of next-generation electronics, marking an exciting frontier in technological innovation.