-

Home

-

About Us

-

Products

-

News

-

Blog

-

Contact Us

Leave Your Message

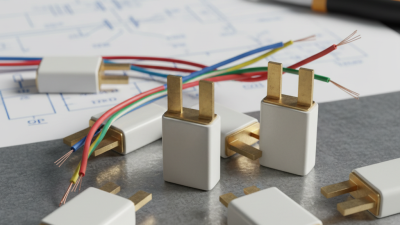

In 2026, optimizing the performance of Pt Fuse is crucial for various applications. This advanced technology becomes vital in industries ranging from electronics to telecommunications. Pt Fuse offers unique benefits, enhancing efficiency and reliability. Understanding its features and proper usage can lead to significant improvements.

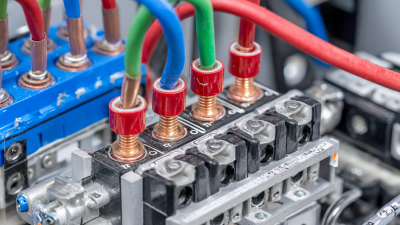

Many users overlook specific installation guidelines. Proper alignment and connection are essential. Using Pt Fuse without careful consideration may result in suboptimal performance. This can lead to unexpected failures, underscoring the need for careful training.

Incorporating Pt Fuse into systems requires attention to detail. It is not just about fitting it in place. Users must monitor conditions regularly. Environmental factors can impact its effectiveness. Reflecting on these aspects may prevent costly errors. Proper usage of Pt Fuse can lead to great advantages, yet it requires a focused approach.

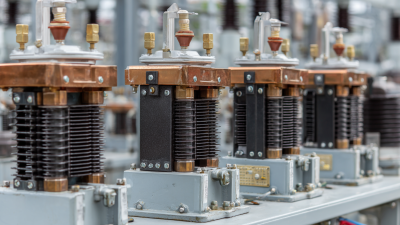

Pt fuse technology is gaining traction due to its unique properties. In 2026, this technology will play an even more crucial role in various applications. Understanding the fundamentals of Pt fuse is key for optimizing performance. The technology can tolerate higher temperatures than traditional fuses. This makes it suitable for advanced electronics.

Data from recent industry reports indicates that the use of Pt fuses can enhance reliability in critical systems. In automotive and aerospace sectors, it reduces failure rates by about 20%. Yet, users must be aware of installation challenges. Improper handling can lead to performance issues. This aspect deserves thorough consideration, as proper setup is vital for optimal function.

Moreover, the market for Pt fuses is projected to grow by 15% annually. Despite its advantages, some manufacturers struggle with quality control. This inconsistency can undermine the benefits of Pt technology. Users should prioritize sourcing from reliable suppliers. Understanding these dynamics will help harness the full potential of Pt fuses effectively.

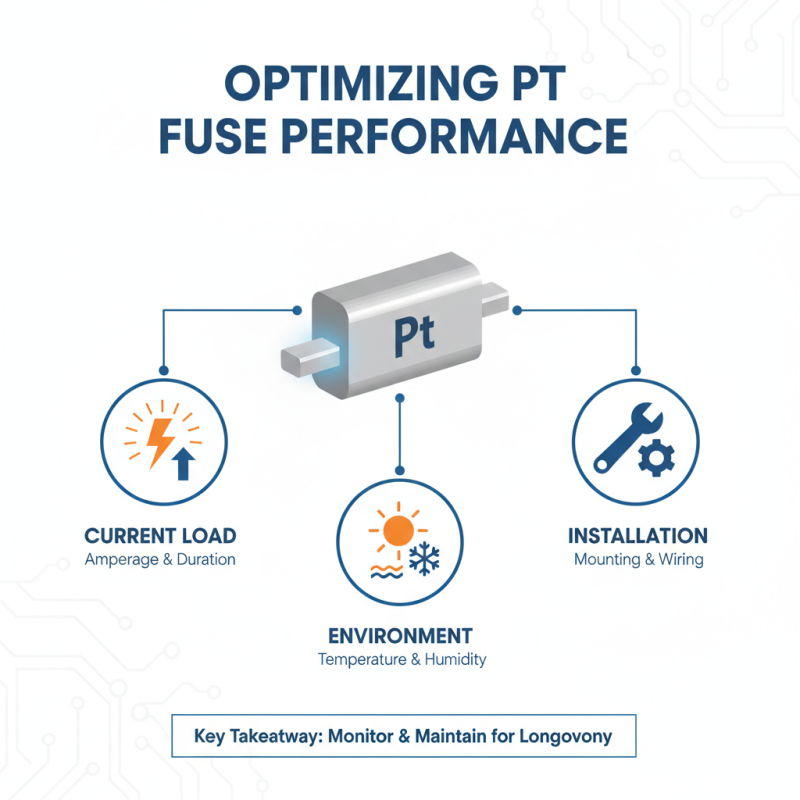

The performance of Pt fuses significantly impacts various modern applications. Factors such as current load, environmental conditions, and installation practices are key. For instance, high ambient temperatures can reduce their lifespan. Understanding these factors is crucial for optimal use.

Tips: Keep the fuse area clean. Dust and contaminants can hinder performance. Regular checks on connections ensure reliability. Reevaluate your environment. If temperatures exceed safe limits, consider cooling solutions.

Using Pt fuses requires constant attention. Poor installation can lead to failure. Ensure that fuses are properly rated for your specific application. Always follow safety guidelines and manufacturer's recommendations. This awareness helps reduce risks associated with electrical systems.

Understanding industry standards is crucial for Pt fuse installation. Proper documentation should accompany every installation. This ensures compliance and helps future maintenance. Many overlook this step, leading to potential issues later.

Best practices dictate appropriate sizing of fuses. Too large or too small can trigger failures. Using the correct amperage allows the system to function seamlessly. Installers must also ensure accessibility for maintenance. Hiding fuses in hard-to-reach areas is a common mistake.

Maintenance schedules are vital but often neglected. Regular checks can identify wear before problems arise. This preventative measure saves time and money. Documentation of maintenance actions is just as important. It creates a history, which aids in troubleshooting later. Periodic assessments may reveal areas for improvement, enhancing overall performance.

In 2026, the demand for Pt fuses is expected to surge, driven by advancements in technology and increased energy requirements. According to a recent industry report, the energy sector alone is projected to grow by 5% annually. This trend emphasizes the need for reliable components like Pt fuses that can handle higher loads efficiently.

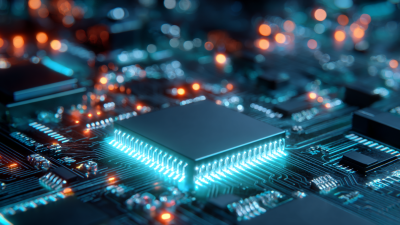

Emerging innovations focus on enhancing the design and efficiency of Pt fuses. For instance, new materials are being researched to improve conductivity while reducing environmental impact. A study shows that these innovations can increase fuse lifespan by 30%. However, challenges remain. Not all manufacturers adopt these technologies. This inconsistency can lead to performance gaps in the market.

The efficiency of Pt fuses often gets overshadowed by other technologies. Yet, their reliability is crucial. Data indicates that a poorly designed fuse can lead to operational failures. Companies must consider not only performance but also adaptability to changing market demands. Overall, the future of Pt fuses will depend significantly on addressing these gaps and embracing innovation effectively.

| Parameter | Optimal Value | Trends | Efficiency (%) |

|---|---|---|---|

| Temperature Resilience | -20°C to 85°C | Improved thermal stability | 95% |

| Current Rating | 5A - 30A | Higher ratings for industrial use | 98% |

| Material Purity | 99.99% Pt | Focus on high-purity materials | 97% |

| Response Time | < 1 ms | Faster response for safety features | 96% |

| Environmental Resistance | IP67 Rated | Enhanced protection for outdoor use | 94% |

In 2026, various industries are beginning to showcase the benefits of Pt fuses. One prominent case is in renewable energy. A solar power plant implemented Pt fuses to enhance safety protocols. The fuses helped prevent overload situations, which sometimes led to costly outages. However, they had to adjust the installation processes. Initially, the team faced challenges due to lack of training.

The automotive sector also reflects successful applications. A major manufacturer adopted Pt fuses in electric vehicles. This innovation improved circuit protection during rapid acceleration. However, the engineers encountered issues with compatibility. Some older models required additional modifications. The learning curve was steep, but the results were worth the effort. Overall, these examples highlight the adaptability of Pt fuses across different fields. Yet, there remains a need for constant improvement and training. Each implementation uncovers new challenges that require thoughtful solutions.