-

Home

-

About Us

-

Products

-

News

-

Blog

-

Contact Us

Leave Your Message

In the ever-evolving field of electrical engineering, selecting the right protective devices is crucial to ensure system reliability and longevity. One such device that has garnered significant attention is the Polymeric Surge Arrester. An expert in the field, Dr. Emily Thompson, emphasizes the importance of proper selection when she states, "Choosing the right Polymeric Surge Arrester can significantly reduce downtime and maintenance costs." This insight highlights the critical role these devices play in shielding electrical systems from transient voltages.

As we approach 2025, the need for effective surge protection becomes even more pronounced with the increasing complexity of electrical networks and the integration of renewable energy sources. Understanding the various types of Polymeric Surge Arresters, their applications, and the key factors influencing their performance can empower engineers and decision-makers to make informed choices. This guide aims to demystify the selection process and provide a clear roadmap for evaluating the most suitable Polymeric Surge Arrester for diverse operational needs. By focusing on the unique characteristics and benefits of these devices, we can enhance the reliability of infrastructure and protect against the unpredictable nature of electrical surges.

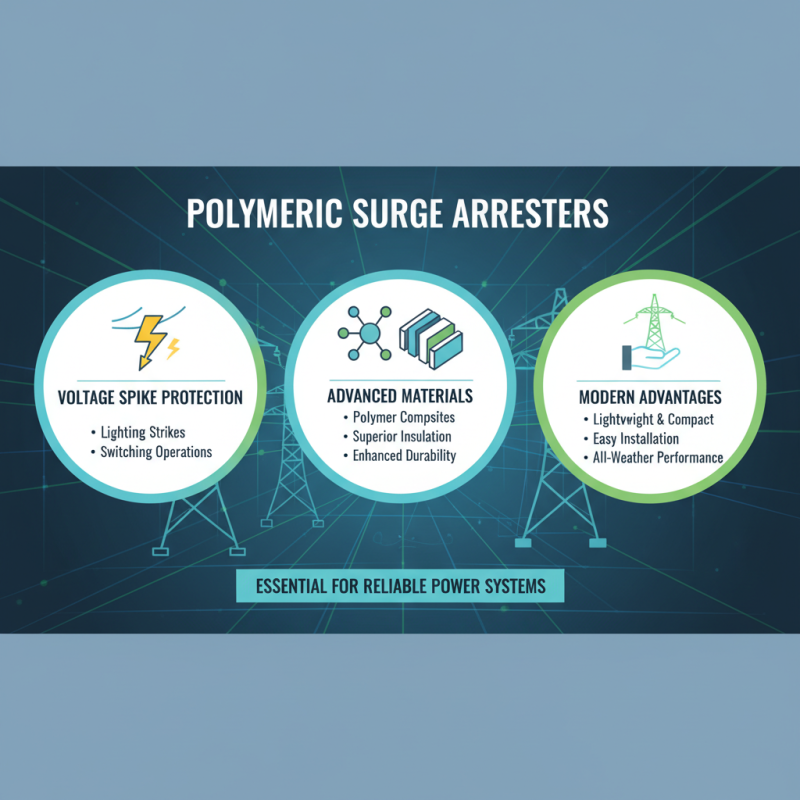

Polymeric surge arresters have emerged as a pivotal component in modern electrical systems, providing essential protection against voltage surges caused by lightning strikes or switching operations. These devices are typically constructed using advanced polymer materials that offer superior insulating properties and durability compared to traditional porcelain or glass options. Their lightweight and compact nature not only makes installation easier but also enhances their performance in various environmental conditions.

Understanding how polymeric surge arresters function is crucial for anyone looking to implement them in their infrastructure. When a surge occurs, these devices redirect excess electrical energy away from sensitive equipment, thereby mitigating potential damage. The materials used in polymeric arresters allow for rapid response times, which significantly improves their effectiveness in protecting electrical systems. Furthermore, the ability to withstand extreme weather conditions, including UV exposure and moisture, makes polymeric surge arresters a reliable choice for both outdoor and indoor applications.

When selecting a polymeric surge arrester, understanding the critical factors that influence performance and reliability is essential. One of the primary considerations is the voltage rating, which should match or exceed the system voltage. This ensures effective protection against voltage spikes, which can occur due to lightning strikes or switching operations. Additionally, the insulation level must be assessed, as it impacts the lightning impulse withstand voltage. Choosing a surge arrester with adequate insulation helps in maintaining operational safety and longevity.

Another key factor is the energy absorption capability of the arrester. This characteristic determines how much energy the device can safely dissipate during a surge event. It is advisable to select a surge arrester with sufficient energy handling capacity relative to the potential surge levels in your application. Furthermore, the environmental conditions, such as temperature and moisture levels, can affect the performance of the polymeric material used in the arrester. Therefore, ensuring the selected arrester is suited for the specific environmental context is crucial for long-term functionality.

Polymeric surge arresters are essential components in electrical protection systems, designed to safeguard equipment from voltage spikes caused by lightning strikes or switching surges. Understanding the different types of polymeric surge arresters and their applications can significantly enhance system reliability. Two primary types include metal-oxide surge arresters (MOSAs) and silicon-carbide surge arresters (SCSAs). MOSAs are known for their high-energy absorption capability and minimal residual voltage, making them suitable for high-voltage substations and critical infrastructure. According to a report from the International Electrotechnical Commission (IEC), over 70% of surge protection failures in electrical systems are attributed to insufficient arrester specifications, underscoring the importance of selecting the right type.

In contrast, SCSAs are more frequently used in lower voltage applications, such as renewable energy systems and urban power distribution networks, where their compact size and lightweight design present practical advantages. A study conducted by the IEEE Power Electronics Society suggests that integrating polymeric surge arresters in photovoltaic (PV) installations can reduce damage from transient overvoltages by nearly 90%, highlighting their effectiveness in renewable energy integration. As the demand for reliable power systems grows, particularly in renewable sectors, understanding the distinct characteristics and applications of various polymeric surge arresters becomes critical for engineers seeking to optimize system performance and ensure equipment longevity.

| Type | Description | Typical Applications | Voltage Rating (kV) | Response Time (ns) |

|---|---|---|---|---|

| Station Class | Designed for use in substation applications, offers high reliability. | Power substations, renewable energy installations. | 36 | 100 |

| Distribution Class | Used in medium voltage distribution networks, compact design. | Urban distribution networks, industrial facilities. | 15 | 30 |

| Line To Ground | Designed for line-to-ground protection in overhead systems. | Overhead power lines, telecommunication lines. | 25 | 50 |

| Harmonic Filters | Optimizes power systems by reducing harmonic distortion. | Manufacturing plants, data centers. | 33 | 60 |

| Metal-Oxide Varistor (MOV) | High energy absorption capability for transients. | Residential and commercial infrastructure. | 20 | 25 |

When selecting the right polymeric surge arrester, understanding performance specifications such as voltage ratings and energy absorption is crucial. Voltage ratings denote the maximum voltage the arrester can handle without failure, ensuring it can effectively protect electrical systems from surges. Moreover, it’s imperative to choose a device that matches the operational voltage levels of your system, as selecting one with inadequate ratings could lead to catastrophic failures and costly downtime.

Energy absorption capacity indicates how much energy the arrester can absorb before reaching its limits. This specification plays a pivotal role in determining the longevity and effectiveness of the surge protection. High energy absorption ratings are particularly beneficial in environments prone to frequent surges, as they guarantee enhanced protection and minimized risk of damage.

Tips for choosing the right polymeric surge arrester include evaluating the expected surge environment, understanding the voltage requirements of your systems, and assessing the potential energy levels you may encounter. It’s also wise to consult with technical experts to verify that the selected device aligns with your specific applications and system configurations. This deliberate approach will ensure optimal performance and protection for your electrical infrastructure.

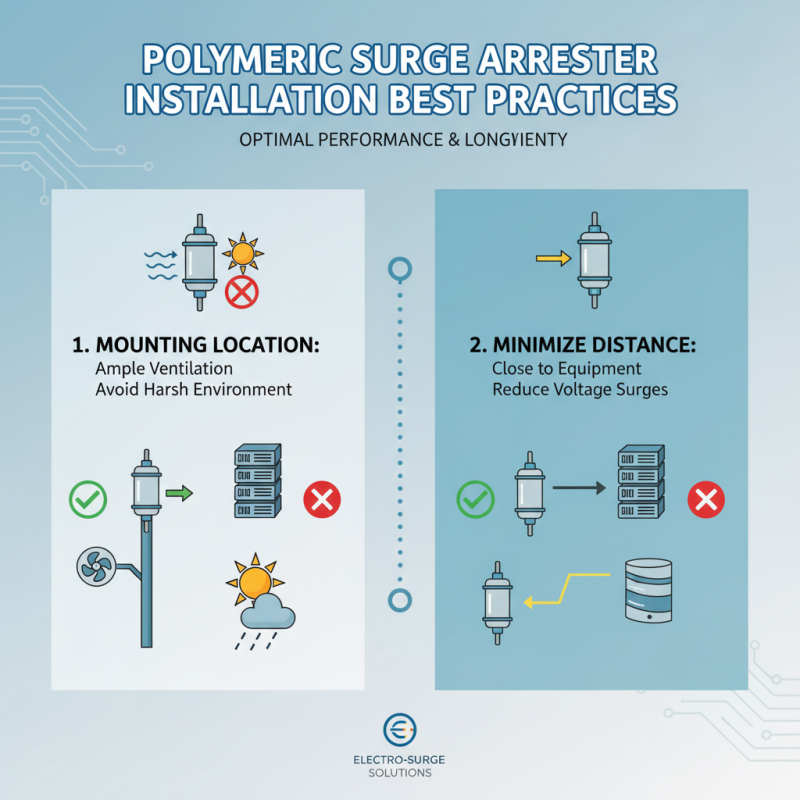

When it comes to installing polymeric surge arresters, it’s essential to adhere to best practices to ensure optimal performance and longevity. First, select an appropriate mounting location that offers ample ventilation and avoids direct exposure to harsh environmental conditions. The arrester should be installed as close to the equipment it protects as possible, minimizing the distance between the arrester and the device to reduce the risk of voltage surges affecting your systems.

Tips: Before installation, conduct a thorough inspection of the surge arrester and its surroundings. Ensure that there are no potential physical obstructions and that the structure can support the installation. Proper grounding is also crucial; make sure that the grounding connection is secure, as it significantly impacts the surge arrester's effectiveness.

Maintenance is equally important in safeguarding against surge events. Regularly inspect and test the arrester to identify any signs of wear or damage. Look for deterioration in the polymer material and ensure that all electrical connections remain secure and corrosion-free. Keeping a maintenance log can assist in tracking the health of the surge arrester and facilitate timely interventions if issues are detected.

Tips: Schedule maintenance checks at least twice a year, and more frequently in aggressive environmental conditions. Utilize thermal imaging to identify any hotspots that may indicate failure points, allowing for proactive repairs before a surge occurs.