-

Home

-

About Us

-

Products

-

News

-

Blog

-

Contact Us

Leave Your Message

In the realm of electrical utilities, safety and performance are paramount, and expulsion fuses play a crucial role in ensuring both. As per the latest industry reports, the global demand for expulsion fuses is expected to grow significantly, driven by the rising need for reliable overcurrent protection in electrical distribution networks. These devices are specifically designed to provide reliable fault interruption while minimizing equipment damage and maintaining system integrity.

According to a report by the Electric Power Research Institute, expulsion fuses have demonstrated a high level of effectiveness in protecting transformers and substations from overload conditions. Their design allows for the safe and efficient expulsion of the fuse element after a fault, preventing arc flash incidents and contributing to overall grid reliability. With an emphasis on safety standards, it is vital for utility companies to remain informed about the latest technologies and regulatory guidelines surrounding expulsion fuses, ensuring optimal performance in their electrical systems.

As we approach 2025, understanding the intricacies and advancements in expulsion fuse technology will be critical for businesses in the electrical sector. This overview aims to provide essential insights into the selection, installation, and maintenance of expulsion fuses, highlighting their importance in enhancing safety and operational efficiency in electrical networks.

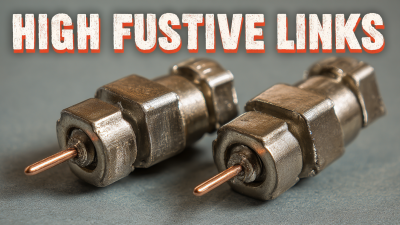

Expulsion fuses play a crucial role in electrical safety by providing overcurrent protection in distribution systems. These devices are designed to interrupt the circuit by expelling the fuse element when a fault occurs. The expulsion mechanism works through a combination of high temperatures and pressure, leading to the rapid ejection of the fuse core as a means to break the fault current. This self-disconnecting feature minimizes the risk of damage to electrical equipment and reduces the likelihood of fire hazards, making them a key component in safeguarding electrical installations.

Understanding the functionality of expulsion fuses is essential for effective implementation. Typically used in overhead power lines and substations, these fuses are engineered to respond quickly to abnormal conditions. When a fault is detected, the fuse melts, creating a hot gas that escapes through a designed vent. This action not only ensures the fuse does its job efficiently but also prevents re-energization of the circuit until the fault is resolved. By recognizing the operational principles behind expulsion fuses, operators can better manage their electrical systems and enhance safety measures across various applications.

| Fuse Type | Voltage Rating (kV) | Current Rating (A) | Breaking Capacity (kA) | Application |

|---|---|---|---|---|

| Type A | 12 | 100 | 25 | Distribution Networks |

| Type B | 15 | 200 | 35 | Industrial Applications |

| Type C | 25 | 300 | 50 | Commercial Buildings |

| Type D | 36 | 400 | 65 | Power Generation |

When it comes to ensuring safety and performance in high-voltage electrical systems, understanding the role and usage of expulsion fuses is paramount. These devices act as protective mechanisms that interrupt electrical faults, preventing damage to equipment and potential hazards. However, several key safety considerations must be taken into account for effective operation.

Firstly, it is critical to select the appropriate expulsion fuse for the specific application, as the wrong type can lead to insufficient protection or failure to trigger during a fault. Additionally, installation must be carried out by qualified personnel who fully understand the operational parameters and potential risks involved. Proper labeling of fuses is also essential to ensure that anyone working on or near the fuse can quickly ascertain its purpose and specifications.

Tips: Always check the manufacturer's guidelines for installation and maintenance routines. Regular inspections can help identify wear and tear, ensuring that fuses remain in optimal condition. Furthermore, consider implementing thermal imaging technology to monitor fuse performance visually during operation. Adequate training for operators on emergency protocols can significantly enhance safety during unforeseen events.

When evaluating performance features of the 2025 expulsion fuses, it is essential to consider key parameters such as interrupting capacity, temperature rating, and operational reliability. A recent report from the IEEE highlights that expulsion fuses with higher interrupting capacities (up to 63 kV) are increasingly becoming a standard for utility applications, ensuring they can safely handle fault currents without compromising system integrity. Furthermore, advancements in material technology have led to improved thermal performance, allowing these fuses to operate efficiently even in extreme conditions, with some models rated for up to 125°C.

Additionally, understanding the installation process and maintenance intervals can significantly impact the longevity and effectiveness of expulsion fuses. According to industry studies, fuses that are regularly inspected and maintained demonstrate a 30% longer operational lifespan compared to those that are neglected. This underlines the importance of integrating routine evaluations and replacing outdated components as part of a proactive maintenance strategy.

Tips: Always check the specifications of the expulsion fuses to match your specific application needs. Regular training for maintenance personnel on the latest features and best practices can also enhance safety and performance. Furthermore, consider utilizing fuse monitoring technology to provide real-time data that can lead to prompt decision-making in emergency situations.

Expulsion fuses are critical components in various electrical systems, designed primarily for overcurrent protection. Typically used in outdoor substations, industrial facilities, and distribution networks, these devices are employed to safeguard equipment from damage caused by short circuits and overload conditions. In applications where reliability and safety are paramount, expulsion fuses provide an effective means of interrupting abnormal current flow. Their operation relies on a simple yet efficient mechanism that expels the fuse element, effectively quenching the arc that occurs when current is interrupted, thus preventing equipment from experiencing further damage.

Common applications of expulsion fuses extend to overhead power lines, where they serve as a key protective feature. These fuses are particularly suited for rural and suburban environments where larger electrical distribution systems must manage diverse loads. Moreover, expulsion fuses are used in transformer protection to prevent faults that could lead to overheating or catastrophic failure. Other integral applications include their use in agricultural and seasonal operations, where they can help maintain the reliability of power supply to essential equipment. The versatility of expulsion fuses makes them indispensable for ensuring consistent performance and safety across various electrical systems, reinforcing their role in modern infrastructure.

Maintaining optimal performance of expulsion fuses is essential for ensuring the safety and longevity of electrical systems. Regular inspection and maintenance practices play a crucial role in this process. One key practice is to routinely check for signs of wear or damage, such as cracked bodies or corroded terminals.

Inspecting the fuse's mounting and connections can prevent overheating, which is often an indicator of poor contact. Implementing a scheduled maintenance program where these inspections are performed can significantly reduce the risk of unexpected failures.

Additionally, environmental factors can greatly influence the performance of expulsion fuses. Dust, moisture, and temperature fluctuations can affect their efficiency, so it's vital to keep the surrounding area clean and dry. Using protective enclosures can help shield fuses from adverse conditions. Furthermore, maintaining proper clearance alongside the fuse installation is important to prevent arcing or other electrical irregularities.

By combining regular inspections with proactive environmental management, the reliability of expulsion fuses can be enhanced, ensuring both safety and optimal operation in electrical systems.