-

Home

-

About Us

-

Products

-

News

-

Blog

-

Contact Us

Leave Your Message

When considering electrical safety and efficiency, the choice of fuses holds great importance. Among the various options available, Ceramic Fuses stand out. They are known for their excellent thermal and mechanical stability. This makes them suitable for high-performance applications. The durability of Ceramic Fuses helps to prevent unwanted interruptions.

Different types of Ceramic Fuses cater to specific needs. Each type has unique characteristics that affect their performance. For instance, some are designed for fast response, while others handle overloads better. Selecting the right fuse is crucial for optimal protection. It is essential to understand which type aligns with your requirements.

Despite their advantages, Ceramic Fuses can present challenges. For example, not all applications benefit equally from these fuses. Some users may overlook critical specifications. Others might fail to realize the importance of choosing the right amperage rating. This could lead to inefficiency or even failures. Understanding these nuances is key to making informed decisions about Ceramic Fuses.

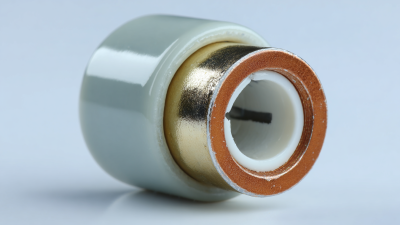

Ceramic fuses come in various types, each designed for specific applications. The most common type is the cylindrical fuse. It usually has a glass or ceramic body and can handle higher voltage applications. They are often found in household appliances and industrial machines. These fuses provide excellent overcurrent protection with reliable performance in diverse environments.

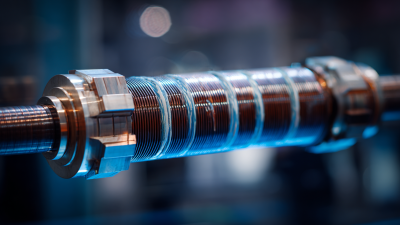

Another popular type is the surface mount fuse. These fuses are compact and primarily used in modern electronic devices. Their small size allows them to fit into tight spaces. However, installation requires careful handling to avoid damaging sensitive components. The thermal and electrical properties of these fuses make them suitable for circuit boards where space is limited.

The blade-type ceramic fuse is also significant in automotive applications. It offers a fast response time for overcurrent situations. However, it is important to select the correct rating to avoid nuisance blowing. Users sometimes struggle with finding the right fuse based on their specific needs. Improper application can lead to performance issues that could have been avoided with better research.

| Fuse Type | Voltage Rating (V) | Current Rating (A) | Applications | Features |

|---|---|---|---|---|

| Standard Ceramic Fuse | 250 | 10-20 | Household appliances | Fast-acting, reliable |

| Time-Delay Ceramic Fuse | 250 | 15-30 | Motors, transformers | Surge protection, slow-blow |

| High-Voltage Ceramic Fuse | 1000 | 1-15 | Industrial equipment | Excellent insulation, robust |

| Miniature Ceramic Fuse | 125 | 0.5-10 | Electronics, lighting | Compact, versatile |

When choosing ceramic fuses for optimal performance, it's essential to understand their key features. High-performance ceramic fuses are designed to provide superior protection. They can handle high temperatures and resist thermal shocks. This durability increases their longevity, making them a preferred choice in many applications.

Another vital aspect is their excellent response time. These fuses can quickly react to overload conditions. This rapid response helps prevent damage to sensitive electrical components. Additionally, ceramic fuses often have a high interrupting rating. This ensures they can safely disconnect from the circuit under fault conditions. However, not all ceramic fuses offer the same level of performance. Choosing the right type requires careful consideration of specific needs.

Moreover, the design of ceramic fuses plays a crucial role. A well-designed fuse ensures efficient operation, but flaws can lead to inefficiencies. For example, improper sizing or using the wrong type can result in unnecessary outages. Even the materials used in the fuse construction matter. Cheaper materials may compromise performance. Being aware of these factors helps in making informed decisions. Finding the right balance is vital for optimal protection and efficiency.

When comparing ceramic fuses to other fuse types, it becomes apparent that each has its merits. Ceramic fuses excel in durability and heat resistance. They are particularly effective in environments with significant electrical surges. According to a recent industry report, ceramic fuses can withstand up to 1,000 volts more than their glass counterparts. This makes them suitable for high-performance applications, where reliability is crucial.

In contrast, glass fuses are more common and often cheaper. However, they lack the heat tolerance that ceramic fuses offer. Some studies indicate that glass fuses may blow under thermal stress much sooner than ceramic options. This can lead to circuit interruptions in critical systems, posing a potential threat in industrial settings. In many cases, manufacturers find themselves weighing cost against long-term reliability.

Interestingly, while ceramic fuses provide higher performance, they may not be the optimal choice for every application. They can be bulkier and sometimes more complex to install. Certain installations might favor space efficiency and cost-effectiveness over sheer performance. These aspects warrant a closer look. The balance between performance and practicality often defines the best choice for fuse applications.

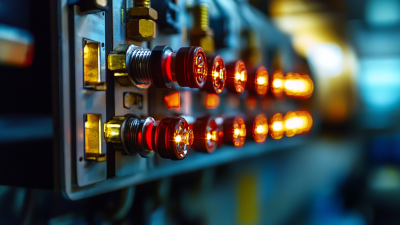

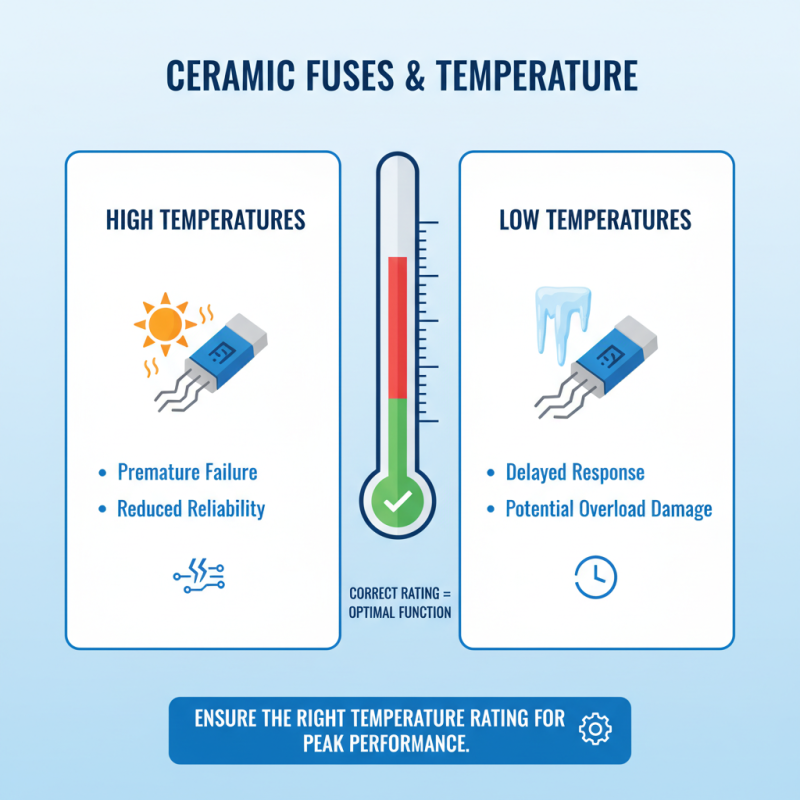

Ceramic fuses are popular for their reliability in electrical applications. However, several factors can impact their performance significantly. One of the primary factors is the temperature rating. High temperatures can lead to premature failure, while low temperatures might result in delayed response to overloads. Ensuring the correct temperature rating is crucial for optimal functioning.

Another important factor is the environment in which the fuse operates. Dust, moisture, and corrosive elements can degrade the fuse and reduce its efficiency. Regular inspections are necessary to identify any environmental threats. Additionally, the installation technique also plays a role. Poor connections can cause arcing and overheating, leading to malfunctions.

The fuse's voltage rating is equally important. Using a fuse with an insufficient voltage rating can lead to catastrophic failures. Underrating can cause a fuse to blow excessively, while overrated options may not trip in emergencies. It’s essential to choose fuses that match the specific requirements of the application for the best performance.

When selecting ceramic fuses, it’s vital to understand their specifications and applications. Different types cater to various needs. For instance, consider the voltage and current ratings. Each fuse type has unique characteristics that affect its functionality. Be mindful of these details during the selection process.

Tips: Double-check compatibility with your electrical system.

Installation requires attention to detail. Make sure to follow manufacturer guidelines closely. Incorrect installation can lead to malfunction or damage. Use appropriate tools for securing fuses to ensure a solid connection. Inadequate tightening could result in failure.

Tips: Label your fuses clearly for easy identification.

Sometimes, it's easy to overlook environmental factors. Humidity, heat, and dust can affect fuse performance. Regular inspection of your fuses is important for maintaining optimal performance. Reflect on any signs of wear or corrosion. It’s a good practice to replace fuses that show any signs of degradation.

Tips: Maintain a spare fuse inventory.