-

Home

-

About Us

-

Products

-

News

-

Blog

-

Contact Us

Leave Your Message

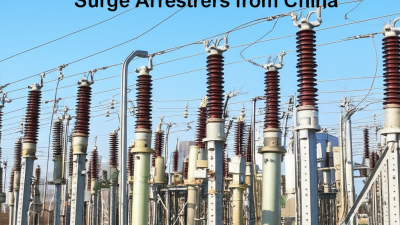

In an era where electronic systems are increasingly vulnerable to weather-related disruptions, the need for robust protection mechanisms has never been more critical. According to recent industry reports, lightning strikes cause an estimated $1 billion in damages annually to power systems and electronic equipment, highlighting the urgency of effective protective solutions. One such solution gaining traction is the Gapless Lightning Arrester, which offers unparalleled protection against voltage surges. Unlike traditional arresters that include air gaps, gapless designs ensure a continuous path for fault currents, significantly reducing the risk of equipment failure. As the demand for reliable power supply intensifies, implementing technology such as Gapless Lightning Arresters becomes paramount for utilities, industrial plants, and commercial enterprises striving for maximum safety and operational integrity.

Lightning strikes can cause severe damage to power systems, leading to extensive downtime and costly repairs. Understanding the importance of lightning protection is crucial for maintaining the integrity and reliability of electrical infrastructure. Power systems, whether they are large-scale utilities or smaller industrial setups, are vulnerable to lightning strikes which can induce transients and surges that exceed the tolerance levels of various components. This makes a robust lightning protection strategy essential for safeguarding electrical equipment.

Lightning strikes can cause severe damage to power systems, leading to extensive downtime and costly repairs. Understanding the importance of lightning protection is crucial for maintaining the integrity and reliability of electrical infrastructure. Power systems, whether they are large-scale utilities or smaller industrial setups, are vulnerable to lightning strikes which can induce transients and surges that exceed the tolerance levels of various components. This makes a robust lightning protection strategy essential for safeguarding electrical equipment.

Gapless lightning arresters provide an effective solution to mitigate the risks associated with lightning strikes. Unlike traditional arresters, gapless designs do not rely on air gaps, which can fail under high-energy strikes. Instead, they utilize advanced materials to ensure continuous protection against voltage spikes. Implementing these arresters not only enhances safety but also improves the overall performance of power systems, allowing them to operate more efficiently without the interruptions often caused by lightning-related incidents. Adopting gapless lightning protection is a proactive step that minimizes the potential for catastrophic failures and enhances the longevity of power infrastructure.

Gapless lightning arresters are becoming an essential component in enhancing the safety and reliability of power systems. Unlike traditional arresters that rely on gas discharge tubes, gapless designs provide uninterrupted protection without any gaps. This approach minimizes the risk of power surges during lightning events, which can cause costly equipment failures and downtime. According to industry reports, gapless technology can reduce lightning-induced outages by up to 90%, making it a smart choice for energy providers seeking to maintain stable operations.

One notable advancement is the implementation of Externally Gapped Line Arresters (EGLAs), which effectively combine the benefits of both traditional and gapless technology. EGLAs can handle high surge currents while maintaining system continuity, essential for modern power line designs. As environmental considerations continue to escalate, power line designers are increasingly gravitating towards EGLAs. Research indicates that integrating EGLAs can lead to significant long-term savings on maintenance and repair costs, answering both operational efficiency and sustainability needs. Such developments reflect the industry's commitment to enhancing power grid resilience in the face of unpredictable weather patterns and rising environmental concerns.

When it comes to safeguarding power systems from lightning strikes, the installation of gapless lightning arresters is a critical measure for achieving maximum effectiveness. Industry reports indicate that electrical surges due to lightning can cause significant downtime and financial loss, with an estimated 30% of all power disturbances originating from such events. To mitigate these risks, the proper installation of gapless arresters requires careful consideration of various factors including arrester placement, grounding systems, and environmental conditions.

Best practices for installing these devices begin with ensuring that gapless arresters are strategically located near sensitive equipment and in areas most prone to lightning activity. According to a study by the IEEE, placing these arresters within 30 meters (approximately 100 feet) of the load they protect can significantly enhance performance. Furthermore, an effective grounding system is essential; grounding resistance should be less than 5 ohms to facilitate immediate dissipation of lightning energy. Regular maintenance checks and ensuring that the installation adheres to the National Electrical Code (NEC) can further optimize the reliability and durability of the protection system. By considering these factors, operators can greatly reduce the risk associated with lightning-induced surges, ensuring the safety and longevity of their power systems.

Routine maintenance and inspection of lightning protection systems are crucial for ensuring optimal performance and safety. According to a report by the National Lightning Safety Institute, lightning strikes cause an estimated $1 billion in property damage annually in the United States alone. Regular inspections help identify any potential weaknesses in the lightning protection system, including wear and tear on gapless lightning arresters, connections, and grounding systems. Ensuring that these components are in top condition is essential, as any lapse can lead to catastrophic damage during a storm.

Tips for effective maintenance include conducting thorough inspections at least twice a year, checking for signs of corrosion or physical damage on arresters, and ensuring that grounding connections are secure and in compliance with local codes. Additionally, it is advisable to keep proper documentation of inspections and maintenance activities to track system performance over time.

Investing in quality gapless lightning arresters can greatly enhance the safety of your power systems. Reports indicate that systems equipped with these advanced protectors can reduce the risk of failure from lightning strikes by up to 30%. Therefore, incorporating routine maintenance and inspections not only safeguards your assets but also prolongs the lifespan of your lightning protection systems.

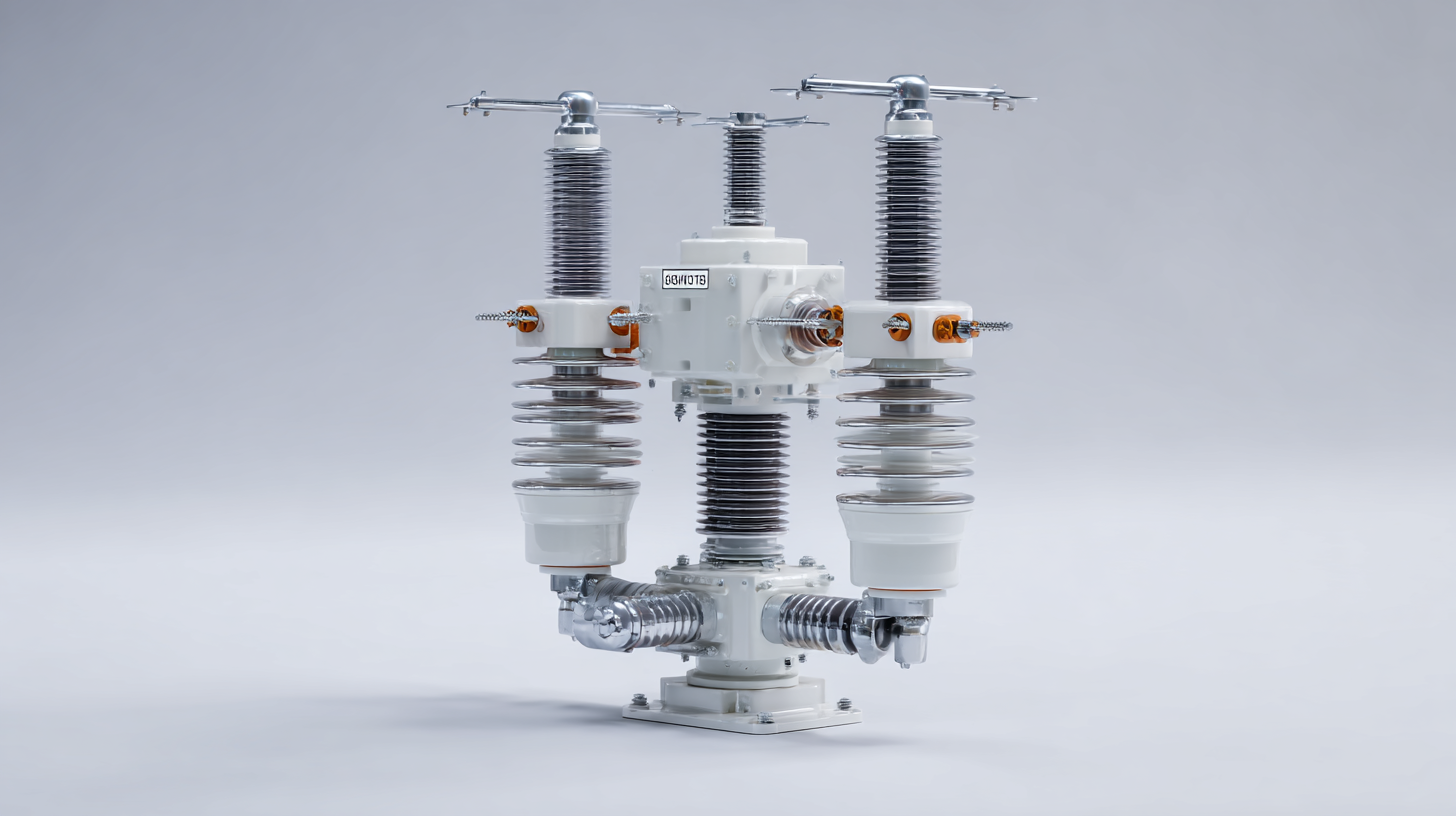

Upgrading existing protection systems with gapless technology is essential for enhancing safety and reliability in electrical power systems. Traditional surge protective devices often rely on spark gaps, which can wear over time and may not provide adequate protection during severe lightning events.

Gapless lightning arresters, on the other hand, utilize advanced materials and design to offer continuous protection without the risk of degradation, ensuring that power systems remain operational even in the face of extreme weather conditions.

The transition to gapless technology not only improves the effectiveness of lightning protection but also simplifies maintenance procedures. Since these devices lack moving parts that can become damaged, the need for frequent replacements is significantly reduced, resulting in cost savings over time. Additionally, gapless arresters can be integrated seamlessly into existing infrastructure, providing a straightforward upgrade path for facilities looking to fortify their defense against electrical surges and improve overall resilience.

This evolution in protective technology empowers operators to maintain high levels of performance while safeguarding their investments in power system reliability.