-

Home

-

About Us

-

Products

-

News

-

Blog

-

Contact Us

Leave Your Message

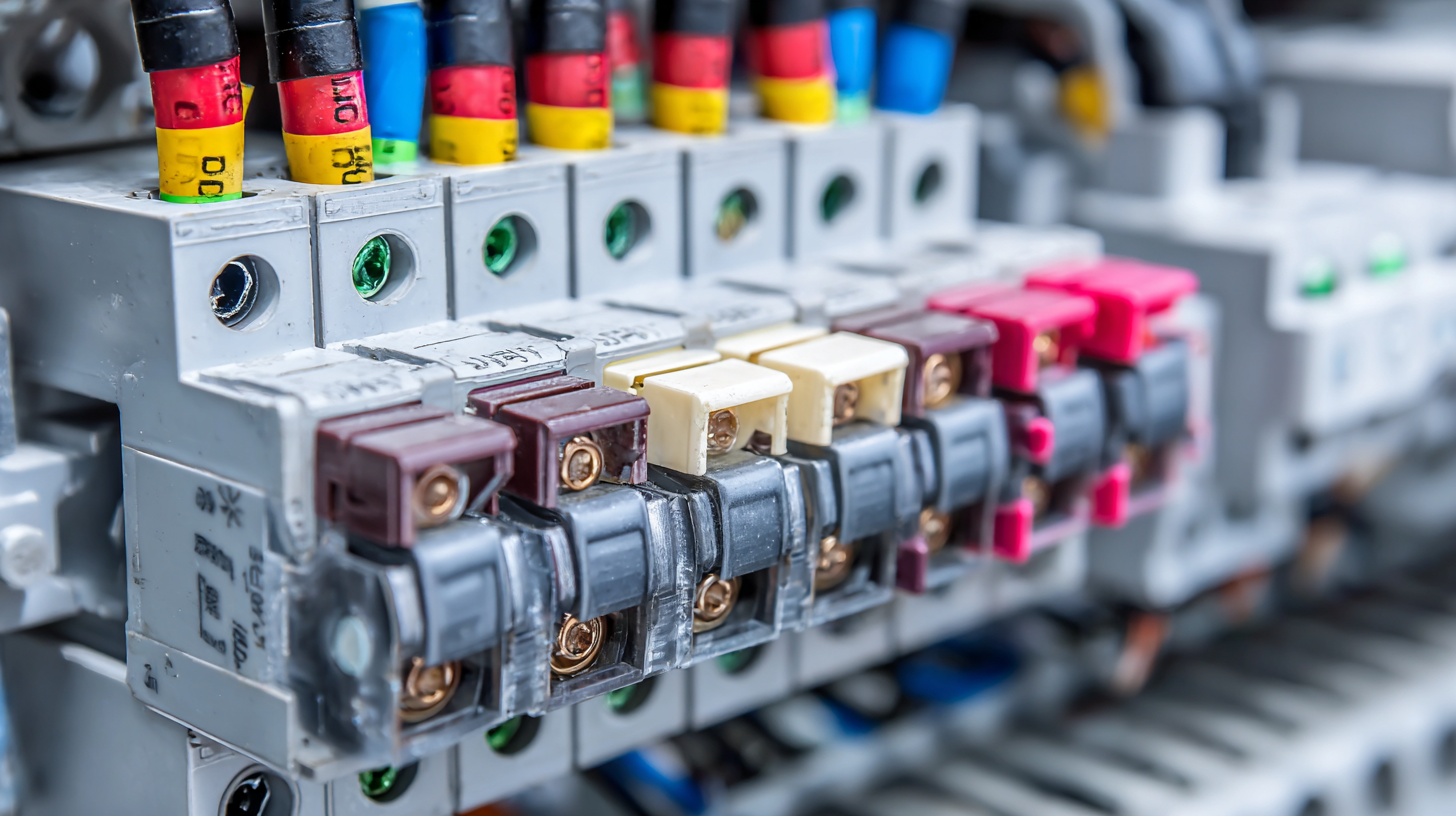

In today's fast-paced technological landscape, electrical safety remains a paramount concern for industries and households alike. With reports indicating that electrical faults account for approximately 23% of fires in industrial settings and around 13% in residential areas, the need for effective protective measures has never been more critical. Among these measures, the Pt Fuse has emerged as a crucial component in enhancing electrical safety. Designed to provide reliable overload protection, the Pt Fuse not only prevents equipment damage but also safeguards against potential electrical fires. According to the National Fire Protection Association (NFPA), the implementation of appropriate fuses can reduce the risk of electrical incidents significantly. Understanding how a Pt Fuse operates and its vital role in the electrical safety ecosystem is essential for both professionals and consumers striving to ensure secure electrical systems.

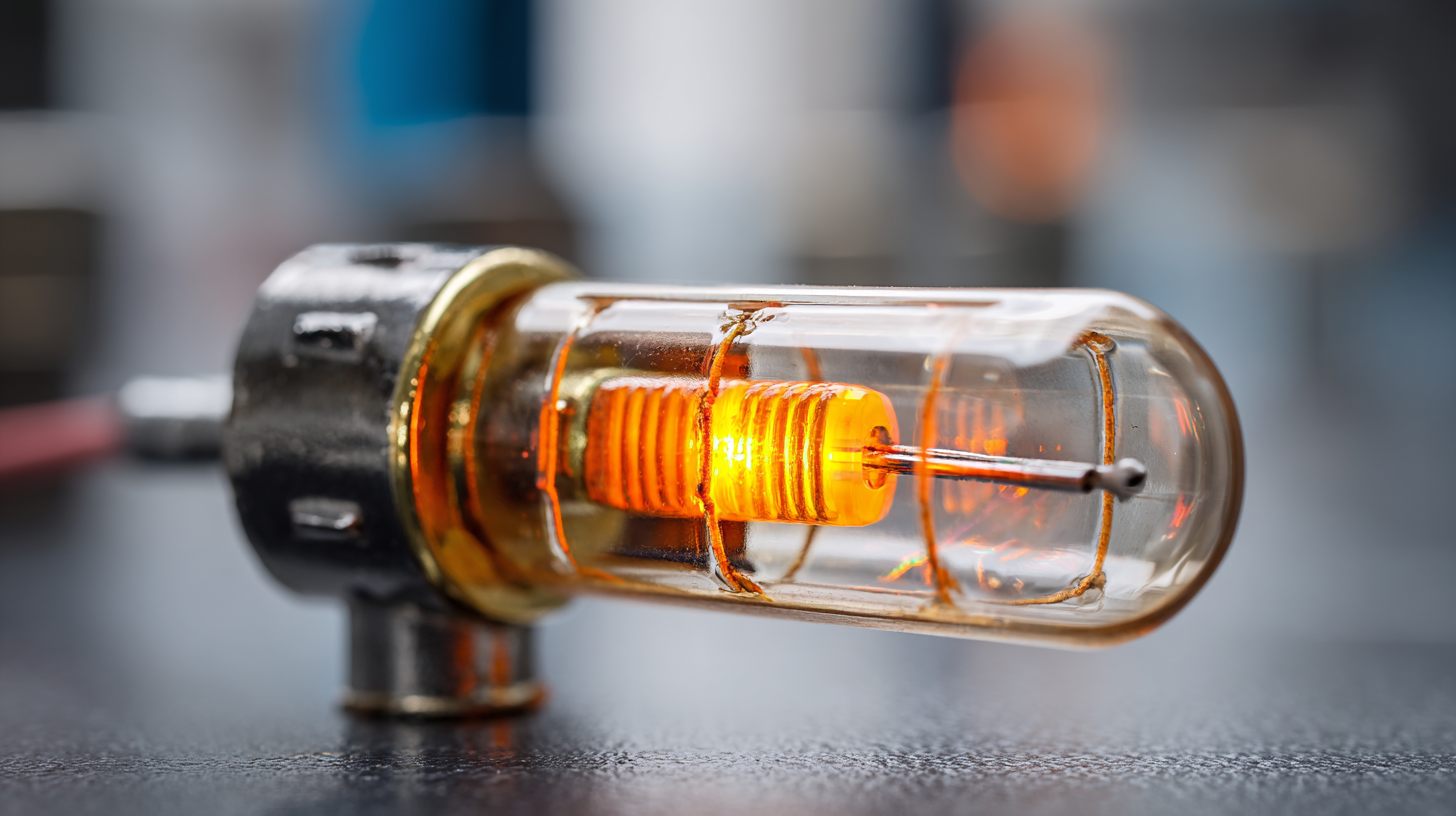

A Pt fuse, or a precision fuse, is a crucial component designed to enhance electrical safety in various applications. Unlike traditional fuses, which may simply break the circuit upon overload, Pt fuses are engineered to provide specific protection for sensitive electronic equipment. They work by responding to fault currents in a precise manner, ensuring that the device is safeguarded without causing unnecessary interruptions to the overall system.

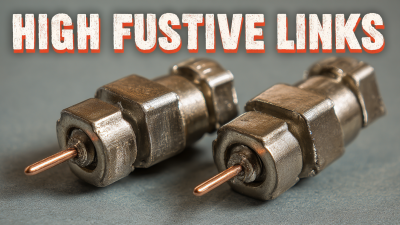

Understanding the basics of Pt fuses involves recognizing their construction and operating principles. Typically made from specially formulated alloys, these fuses exhibit predictable melting characteristics under defined current loads. When an overload occurs, the fuse melts at a specific temperature, effectively interrupting the electrical flow and preventing potential damage to downstream components. This reliable performance makes Pt fuses an essential choice in various industries, including telecommunications, automotive, and renewable energy, where maintaining circuit integrity is paramount.

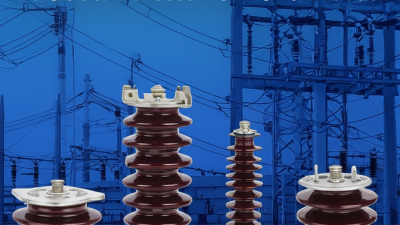

Pt fuses, or protection transformers, play a critical role in enhancing electrical safety within various systems. Their primary function is to safeguard electrical circuits by interrupting excessive currents that could potentially lead to catastrophic failures. In doing so, they help protect sensitive equipment and prevent electrical fires, ensuring the reliability of power distribution. By using Pt fuses, engineers can create safer working environments and prolong the lifespan of electrical components.

Pt fuses, or protection transformers, play a critical role in enhancing electrical safety within various systems. Their primary function is to safeguard electrical circuits by interrupting excessive currents that could potentially lead to catastrophic failures. In doing so, they help protect sensitive equipment and prevent electrical fires, ensuring the reliability of power distribution. By using Pt fuses, engineers can create safer working environments and prolong the lifespan of electrical components.

Tip: Regularly inspect and maintain Pt fuses to ensure they are functioning correctly. This proactive approach can prevent unexpected failures and costly downtime in electrical systems.

In addition to their protective capabilities, Pt fuses also serve as a means of isolation during maintenance. By disconnecting the system during repair work, these fuses help to protect technicians from electric shocks. This essential aspect significantly reduces the risk of accidents in environments where electrical systems are frequently serviced.

Tip: Always ensure that appropriate safety gear is used when working on or near Pt fuses. This includes insulated gloves and tools to minimize the risk of electrical hazards.

Protecting electrical systems from overloads and failures is crucial in maintaining operational safety. Pt fuses, or protection fuses, offer a reliable solution by interrupting the current flow when it exceeds safe limits. According to the National Fire Protection Association (NFPA), electrical failures are one of the leading causes of fires in industrial settings, accounting for over 10% of all reported fires in the U.S. By incorporating Pt fuses, businesses can significantly reduce these risks, as they are designed to react quickly to overcurrents, minimizing potential damage to electrical components and ensuring user safety.

To enhance safety further, regular maintenance of electrical systems, including the inspection of Pt fuses, is essential. Studies indicate that 30% of electrical failures could be prevented through routine checks and timely replacements. Tip: Always keep spare fuses on hand to ensure quick replacements during a failure, which can prevent prolonged downtime and potential hazards. Additionally, consider employing thermal imaging to detect hotspots in electrical infrastructure, allowing for proactive measures before any fuse is required to activate.

By integrating Pt fuses into electrical systems, companies not only adhere to safety regulations but also reinforce the reliability of their equipment. The latest reports suggest that systems equipped with modern fuses experience up to a 70% reduction in unplanned outages, demonstrating the critical role these devices play in efficient electricity management. Tip: Invest in smart fuses that provide real-time monitoring and alerts, further enhancing safety and operational performance.

When integrating Pt fuses into electrical systems, proper installation is paramount to maximizing their safety and efficiency benefits. According to the National Fire Protection Association (NFPA), improperly installed fuses can lead to electrical fires, accounting for over 22,000 cases annually in the U.S. Thus, ensuring that the fuse rating matches the circuit's load requirements is crucial. Overrated fuses may not trip in overcurrent situations, while underrated fuses can blow too frequently, causing unnecessary interruptions.

Additionally, the placement of Pt fuses is essential. They should be easily accessible for maintenance and testing, and all electrical connections should be tight to prevent overheating. The Institute of Electrical and Electronics Engineers (IEEE) recommends regular inspections of fuses every six months to identify any signs of wear or failure early on. Opting for high-quality fuses from certified manufacturers further enhances reliability, as studies indicate that approximately 30% of electrical failures can be attributed to inferior components. By following these installation tips, users can significantly enhance the performance and safety of their electrical systems.

When discussing electrical safety, one common misconception about pt fuses is that they are only effective in protecting against overloads. While it is true that pt fuses can prevent overheating and potential fires caused by excessive current, they also play a crucial role in safeguarding sensitive electronic equipment from voltage spikes. Many users overlook this protective aspect, leading to costly damages that could have been avoided with proper fuse selection.

Another common myth is that all fuses are created equal. In reality, pt fuses are designed with specific characteristics tailored to various applications, ensuring they respond appropriately to irregular current levels. This misunderstanding can lead to improper installations and an increased risk of electrical hazards. By educating users on the nuances of pt fuses, we can promote safer electrical practices and highlight the importance of choosing the right fuse for the right job.

| Dimension | Description |

|---|---|

| Definition | A Pt Fuse is a type of fuse that uses a pressure-sensitive element for electrical protection. |

| Functionality | It provides overcurrent protection by interrupting the circuit when current exceeds safe levels. |

| Common Misconception | Some believe that Pt fuses can be reset after tripping, which is false; they must be replaced. |

| Safety Enhancement | They minimize the risk of electrical fires by ensuring circuits are disconnected when faults occur. |

| Installation Location | Pt fuses are typically installed in main electrical panels or distribution boards. |

| Maintenance | Regularly check for signs of wear or damage and replace fuses as part of routine maintenance. |